The rate of cooling during the cryopreservation of cells can have a substantial impact on long-term cell viability. Cooling too rapidly can cause lethal intracellular ice to form, because cells do not dehydrate sufficiently. Cooling too slowly has the opposite effect, maximizing dehydration but resulting in the accumulation of cryoprotective medium that can be toxic to cells. When freezing biologics, most cell types benefit from an optimized and controlled cooling rate.

To protect cells during cryopreservation, controlled-rate freezers make sure freezing protocols are accurate and reproducible. However, as with all equipment, there is a risk of power interruption, whether it is the result of grid supply issues, power surges, power cuts, or safety features activating within the laboratory infrastructure.

If there is a power interruption, these types of systems will perform an unplanned but safe shut down, then reboot when the power is reconnected. The VIA Freeze system is a controlled‑rate freezer incorporating substantial insulation to protect samples from the ambient air temperature. This study tested the effects of a simulated power interruption on the VIA Freeze controlled-rate freezer for up to 10 minutes at different stages of the cryogenic freezing process from a thermal and biological standpoint, assessing post-thaw cell viability.

The thermal effects of interrupted cooling during cryopreservation

Method

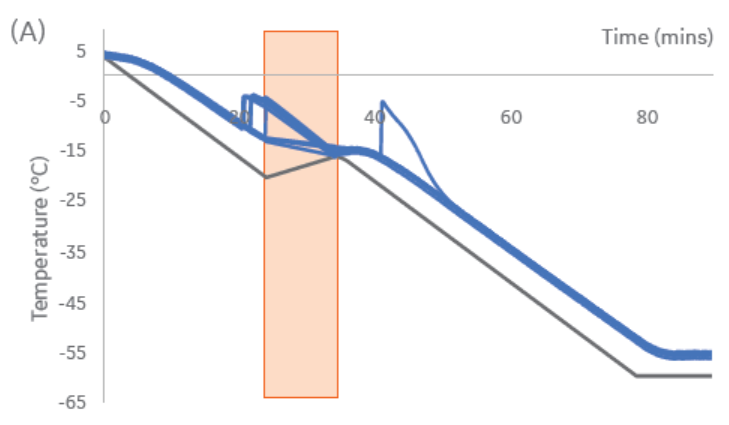

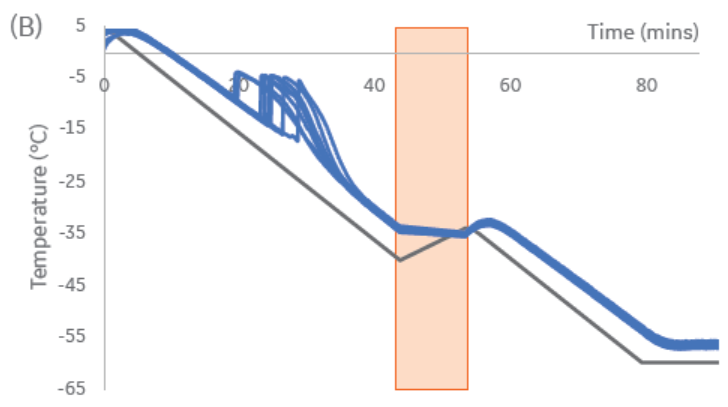

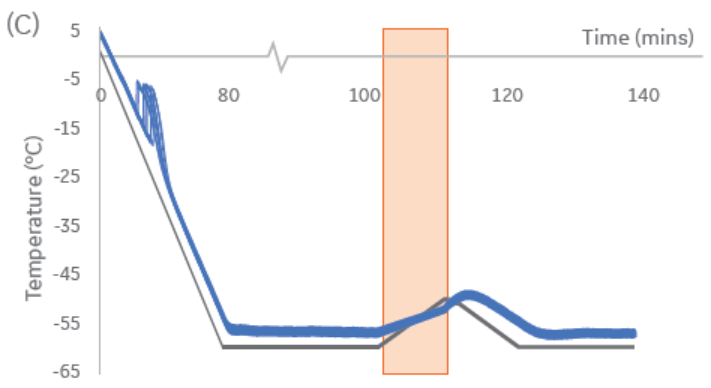

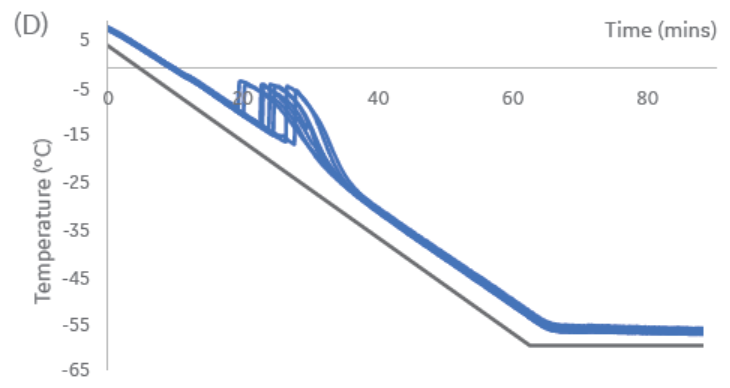

Four separate cooling runs at 1°C/min were carried out in a VIA Freeze controlled-rate freezer with a thermocouple placed in eight 2 mL cryovials, containing 1 mL of 10% (v/v) DMSO in isotonic saline, to monitor sample temperature. During three of the runs, power interruption and reboot were simulated by aborting the cooling process when the program reached selected temperature points, either -20°C, -40°C, or -60°C. After 10 minutes the program was re-started and the average temperature increase of the vials calculated (Table 1). The fourth run proceeded to -60°C and was held there without interruption.

Table 1. Vial temperatures recorded immediately before initiation of a 10-minute simulated power interruption, and the observed increase in vial temperature

| Interruption temperature (°C) | Mean vial temperature on failure (°C) | Mean maximum vial temperature after failure (°C) | ∆T (°C) |

| -20 | -7.7 | -14.6 | < 0 |

| -40 | -34.0 | -32.7 | 1.3 |

| -60 | -57.0 | -49.1 | 7.9 |

Results

At -20°C, there was no observed increase in temperature, which is due to the relatively small difference between vial and ambient temperature, as well as residual cooler components in the VIA Freeze system. The 1.3°C fluctuation in temperature observed during the power interruption at -40°C is lower than that typically experienced during nucleation events in vials, and it is similar to cooling profiles that incorporate a ‘hold’ step at lower temperatures. This level of fluctuation would not typically be damaging to cells. The larger increase of 7.9°C in temperature seen at -60°C can be attributed to the greater difference between the VIA Freeze system at shutdown and external ambient temperature compared to the other temperature points.

Fig 1. The impact of cooling on a cryovial temperature and the program set point during a simulated power interruption. (A) interruption at -20°C, (B) interruption at -40°C, (C) interruption at -60°C, and (D) no interruption. The VIA Freeze setpoint is shown in gray, with each of 8 thermocouples in blue. Simulated power interruption is shown in orange shading.

This increase is equivalent to holding a vial in ambient air for several seconds, and typical of the process of transferring samples between a controlled-rate freezer and low temperature storage. Crucially, the vials remained below the intracellular glass transition temperature, meaning the intracellular compartments remain solidified.Figure 1 indicates that all vials experience homogeneous temperature profiles before and after nucleation (seen as a temperature spike when ice forms), even in the presence of a power interruption.

The biological effect of power interruptions during cryopreservation

Method

To test the biological impact of power interruption, 20 cryovials, each containing 1 mL of 3 × 106 cells/mL (Jurkat cell line-human immune suspension), were cryopreserved at a rate of 1°C/min in 10% DMSO. Four separate cooling runs were carried out with five replicate cryovials in each. Three of the cooling runs had a simulated power interruption for 10 minutes, at either -20°C, -40°C, or -60°C. A fourth run proceeded to -60°C and was held there without interruption.

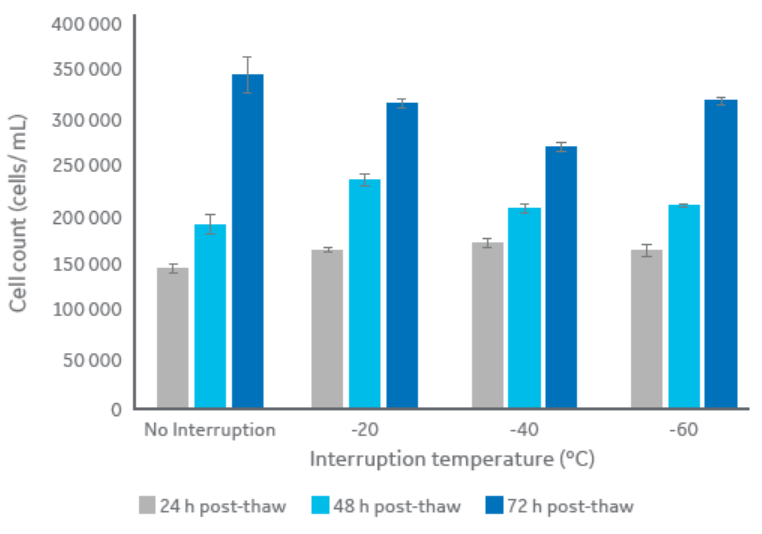

All samples were transferred to low temperature storage at -140°C for at least 24 h. These samples were thawed using a dry, automated vial thawer. Cells were thawed, cultured under normal conditions for 24, 48, and 72 h, then tested using a Cytell Cell Imaging System (Cytiva) (Fig 2).

Results

No substantial difference in post-thaw cell viability or proliferation ability is observed between samples experiencing a power interruption at any measured temperature, or a control where no interruption occurred (Fig 2). These results agree with the data recorded in Figure 1 and Table 1.

Fig 2. Viable cell count for Jurkat cells cultured under normal conditions for 24, 48, and 72 h post-thaw when experiencing a simulated power failure at -20°C, -40°C, or -60°C during the cryopreservation protocol; n=5 ± SD.

Conclusion

This study demonstrates that there is no biological impact in Jurkat cells resulting from a 10-minute power interruption at any stage of the cryopreservation process when using the VIA Freeze controlled-rate freezer. For additional protection, where extended power failures are likely, an Uninterruptable Power Supply (UPS) can be installed between the mains electricity and the controlled-rate freezer to provide backup power and minimize the risk of an extended shutdown in the event of a power cut.

Find out more about Cytiva’s GMP-ready systems that support the cryopreservation of cells.