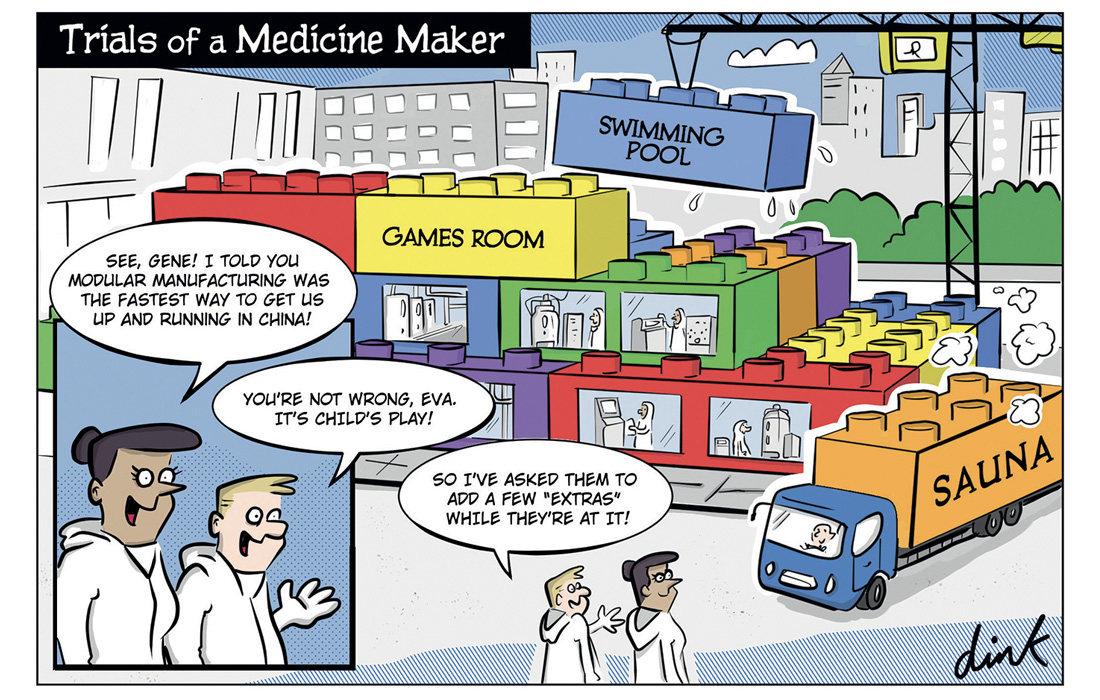

What would you add to your biomanufacturing facility if you had the chance? Gene’s sauna might be out of the question. But going for a prefabricated facility can add more benefits than you might imagine.

Wow, Gene really has some nice ideas for upgrading the facility…Ok, so a pool might be pushing it, but prefabricated facilities sure help reduce capital risk and time to market. Gone are the days when setting up a cGMP manufacturing facility took years to build and validate.

In fact, prefabricated facilities can help slash factory construction time in half, going from three years down to just 18 months. According to an internal study, costs can also be reduced 25% to 50% compared to building a traditional facility. The environmental impact is also smaller, with a 75% reduction in CO2 emissions plus an 80% decrease in water and energy use.

Changes in the bioprocessing market demand new ways of thinking. How do you scale up to produce the new treatments needed? How do you satisfy regulators while minimizing both financial and production risks? Our flexible solutions can help you deal with this complexity. Read why Pfizer decided to go for a prefabricated facility in China.