In environmental testing, filtration is commonly used to remove insoluble particles – but how do you prevent problems such as back pressure build-up?

Preparation of water samples for environmental monitoring assessment often involves dealing with insoluble particles that need to be removed by filtration.

For example, water samples taken for heavy metal or organic compound testing can differ greatly, ranging from clear surface water to water containing dissolved sediment, sludge, and/or soil.

Some of these samples contain high levels of particulates that can cause filtration difficulties, such as back pressure build-up in a syringe. In this post, we talk about how prefiltration can save time, waste, and your thumbs.

Why is filtration necessary?

Filtration should yield a sample free from insoluble particles, ready for analysis without negatively impacting the instrumentation. Filters capable of handling samples with a high particulate content simplify this process.

Back pressure build-up

When using a syringe filter to prepare high-particulate samples, rapid clogging of the filter device is a common occurrence. Dealing with back pressure will almost certainly cost time to handle the challenging sample. It can also cost money if multiple filters need to be used to filter the sample, and sample could be lost. Rarely, the filter membrane can be damaged from excessive pressure and compromise the quality of the sample.

From an ergonomic point of view, daily use of a syringe filter with significant back pressure can lead to hand strain and painful thumbs; then painful forefingers; then whichever fingers you have left to press the plunger…

Alleviating pressure

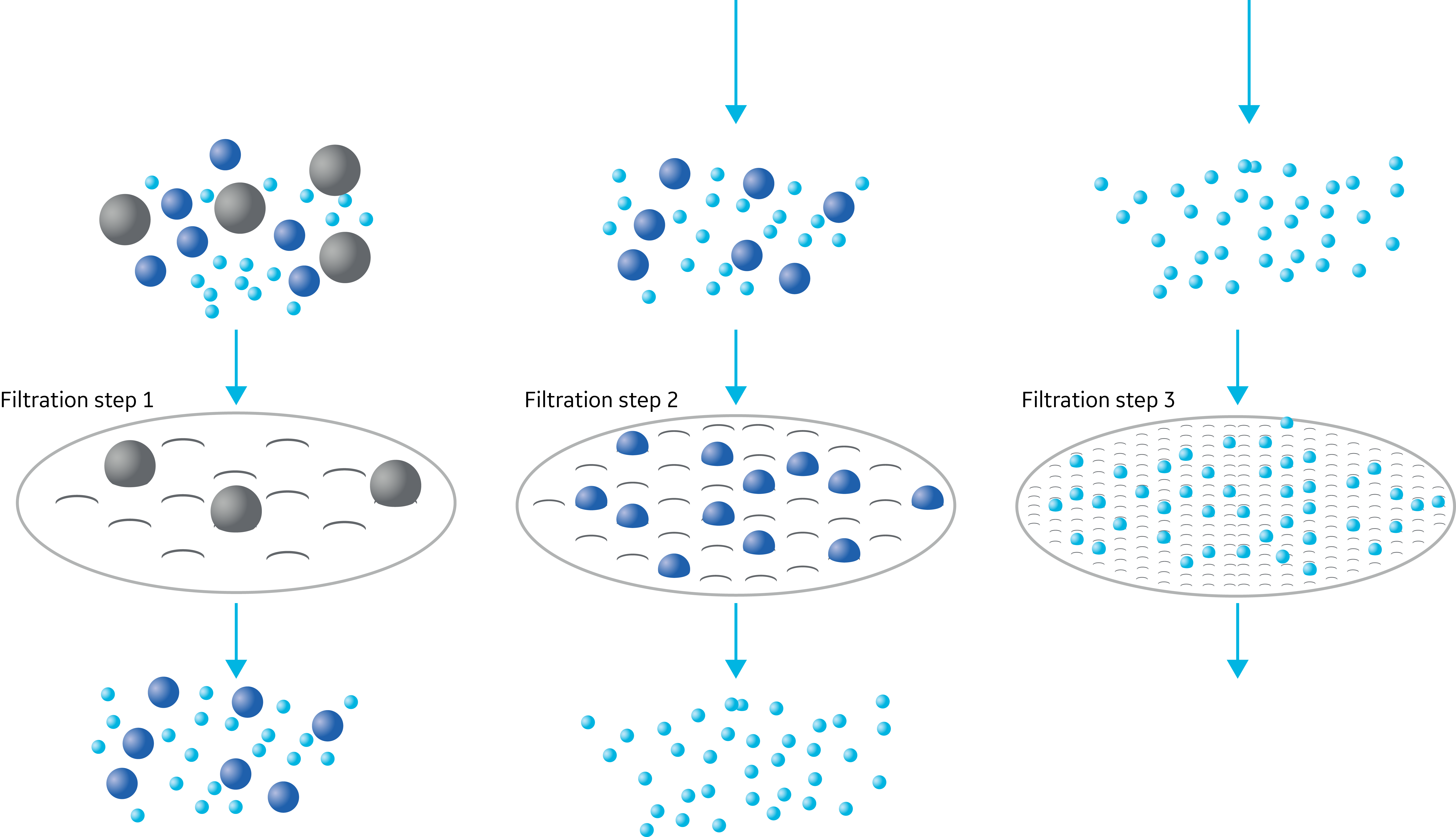

So, what can you do about back pressure build-up? One method to minimize these problems is to use a series of different filters—starting with a large pore size to remove the fraction of larger particles before successively reducing pore sizes—until you remove all the remaining particles.

However, the use of multiple filters for each sample means using more consumables, which can be a bit wasteful in terms of cost and precious lab time. Hold-up volume, the amount of sample that remains in the filter, is also a consideration. When you use multiple filters, you multiply the small fraction of sample you cannot recover.

A better option, in terms of sample loss, time, and number of consumables, is the use of a stacked filter dedicated to filtering high-particulate samples.

Stacked filters

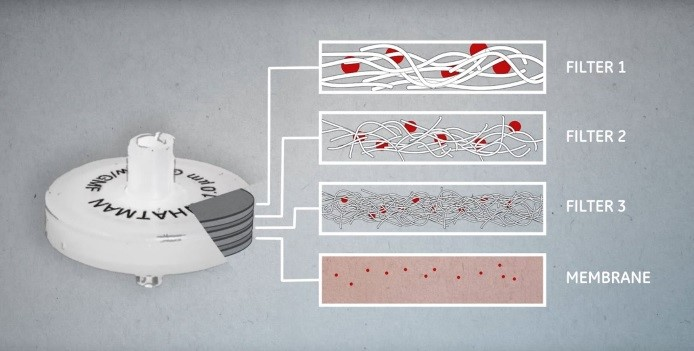

Designed to tackle hard-to-filter samples, a stacked syringe filter consists of multiple glass fiber layers with different porosities, enabling, for example, smooth sludge and soil filtration.

By trapping large particles in the filter’s top high-porosity layer, smaller particles can continue through the layers until captured, with only the finest particles reaching the membrane.

This multilayer filter approach successfully filters all particles of the specified size range without build-up of back pressure or clogging. This design makes stacked filters well suited for the high particulate water samples taken for environmental monitoring, and for saving your thumbs!

We design our GD/X filter devices with these common issues in mind. Watch our short video on solving your back-pressure problems.

The Whatman GD/X range of filters integrates prefiltration stacks, with up to three layers for removing large particles. These filters are available in more than ten different membrane materials, including regenerated cellulose, and in pore sizes ranging from 5 µm down to 0.2 µm.

Request a sample GD/X filter now or use our Whatman Filter Selector Tool to see which GE product is most appropriate for your filtration needs.