Consider particle retention, loading capacity, and liquid flow rate when choosing a filter or device to help improve laboratory efficiency.

Do you often wonder whether your laboratory is functioning as efficiently as it could be? Laboratory efficiency is important to minimize costs, improve results, and increase the number of analyses that can be run in a given time.

Of course, there are many areas and processes in your laboratory that can affect overall efficiency. But filtration is a key step in your analyses that can benefit from an efficiency review.

Perhaps there is a better filter out there for your application. Or perhaps your analysis might be easier, quicker, or produce results that are more consistent if you switched your filter to a different grade. Here we discuss some basic filtration principles and describe the most important considerations when selecting a filter for your application.

Choosing your filter - what should you consider?

Although most paper filters might look alike, they can have a dizzying number of technical differences. These differences are meant to ensure that the filter being used is optimized to support the analysis being performed. But the sheer number of filter options also presents a risk of choosing one that is not fit for purpose.

A lab’s reputation depends on reliable, consistent, and repeatable analysis. A filter choice is one of many things that can have an impact!

Here are three key characteristics to consider when identifying the right filter —particle retention, loading capacity, and liquid flow rate. These all influence the effectiveness and speed of filtration.

- Particle retention

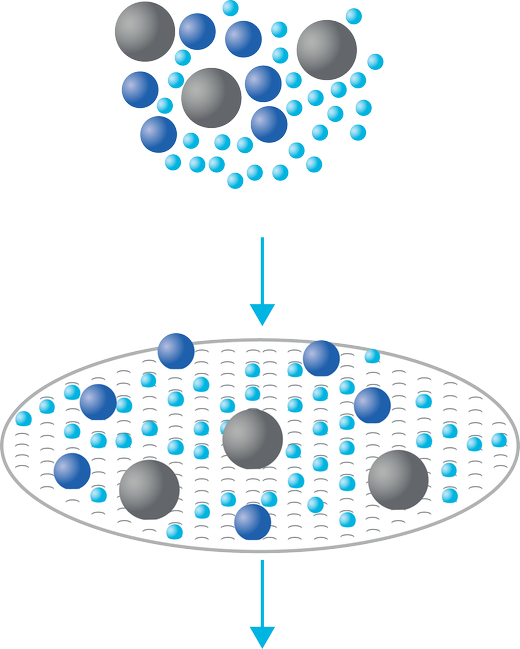

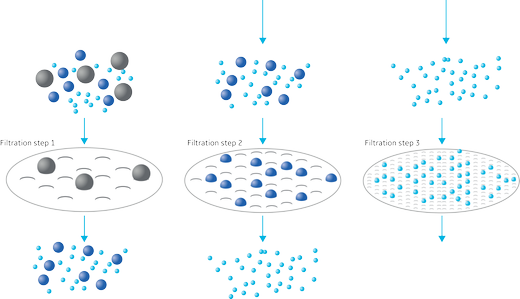

The particle retention of a filter denotes the size of a particle that will be retained and is often expressed in micrometers (µm or microns). For cellulose and glass microfiber papers, it is expressed as a “nominal retention rating”, and quoted at 98% efficiency to allow for secondary filtration effects. For membrane filters with defined pore sizes, it is an absolute retention rating. The lower the particle retention value of a filter, the smaller the particles that will be retained.

Make sure that you know the particle size of the compound you’re looking to filter from solution, as well as the compound size you want to let pass through the filter. Then select a paper with a slightly smaller retention rating than the particle to remove. For example, if you need to remove a 5.8 µm diameter particle from an aqueous solution, consider a filter with a 5 µm retention rating.

If you have multiple compounds with different sizes to filter, then you have two options.

- If there aren’t any particles to be retained in the sample with sizes that fall between the diameters of particles to remove, you can use a filter with a retention rating smaller than the smallest particle to filter.

- If you need to retain a particle that falls between the sizes of multiple compounds in solution, then you might need to take a systematic approach. In this case, you could use multiple filters with retention ratings appropriate to remove one compound at a time, while retaining the compound of interest.

- Loading capacity

The loading capacity of a filter is related to its ability to load particulates into its fibrous matrix. It is common to want a high loading capacity, but there are trade-offs.

Filters with the highest loading capacities are chemically treated and are more expensive than their untreated counterparts. Treatment might also interfere with analysis. This can happen either through chemical interaction with the sample or by increasing the time to results due to a slower flow rate than that of an untreated filter.

By knowing the weight of filtrate that you want to retain on the filter, you can choose a filter that will safely accommodate your needs without the downsides of a filter that is more complex than is needed.

- Liquid flow rate

The flow rate describes the speed at which a liquid flows through the filter. In practice, this is dependent on several factors that will often be specific to the solid/liquid being filtered. But, for comparison purposes, a typical water flow rate is measured and provided for each grade under gravity and normalized to a certain diameter.

After you know the retention rate and loading capacity of the filter you’re looking for, compare your options to understand roughly which filters support higher flow rates and which support lower ones.

Ultimately, your decision will come down to the requirements of your work – do you have a sample that needs to be filtered immediately, or can the sample be left alone to be filtered in due time? Is a specified liquid flow rate required and maintained by either positive or negative pressure? If so, choose a filter with a rating that can support these requirements without tearing!

Here are three key characteristics to consider when identifying the right filter —particle retention, loading capacity, and liquid flow rate. These all influence the effectiveness and speed of filtration. Stayed tuned to the blog for more key information around choosing the best filter for your needs.

Try our Whatman Filter Selector App to find out if you are using the most appropriate filtration solution for your samples. To discuss any challenges you are facing, please contact GE Healthcare Life Sciences.