Ready-to-use(RTU) filters save time and money.

Wastewater flowing into wastewater treatment plants originates from industrial plants, domestic sewage, and rainwater runoff. Specialized testing laboratories work 24/7 to ensure that the water that is released after treatment meets purity standards to protect the community and the plants and animals that live in and around the waterways.

The sample filtration tests performed at wastewater treatment plants must meet federal regulatory standards. The volume of test can be high, and lab managers take a robust approach to understanding where her team must spend their time and how it can be optimized.

Gravimetric assessment to measure the Total Suspended Solids (TSS) in each sample is a common practice in effluent testing.

- In the US, TSS is determined by using Method 2540 C, D, and E, the standard filtration method approved by the Environmental Protection Agency (EPA).

- In Europe, EN 872 describes a standard method for suspended solids measurement in water. It specifies the equipment and materials that are suitable for determining TSS.

Although most countries have their own testing standard, it is likely based off one of these two methods. For example, the British standard BS EN 872:2005 is derived from EN 872.

US Method 2540 C, D, and E passes a sample of water through a glass microfiber filter and measures:

a. the solid residue left on the filter (suspended solids)

b. the solid residue from the filter that incinerates at high temperatures (volatile solids), and

c. the solids residue present after evaporating the water that passed through the filter (dissolved solids)

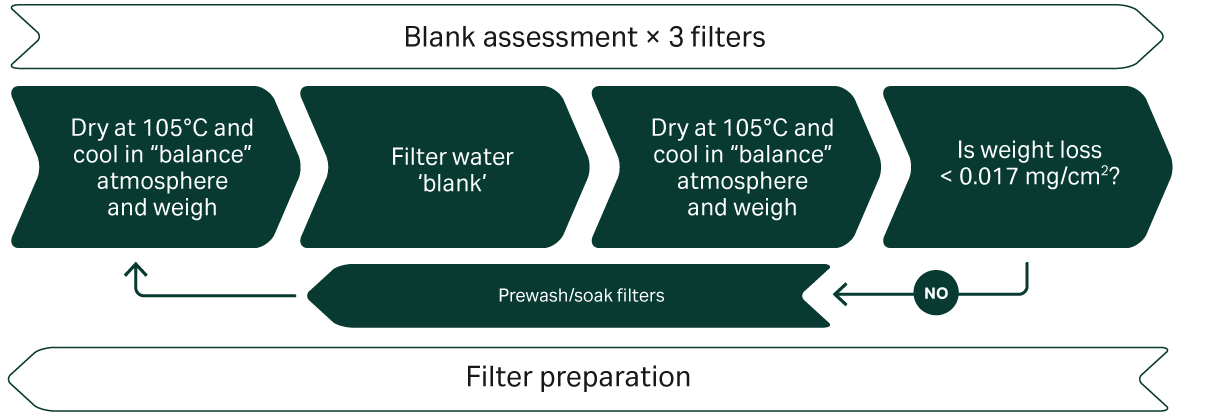

Because of the critical nature of the filter in this process, this (US) method states that it be binder free glass fiber and be prepared according to specific steps prior to use. Specifically, it should be rinsed three times, then dried and weighed until a constant weight is obtained. In testing for volatile suspended solids (VSS), the filter must also be ignited in a furnace at 550°C.

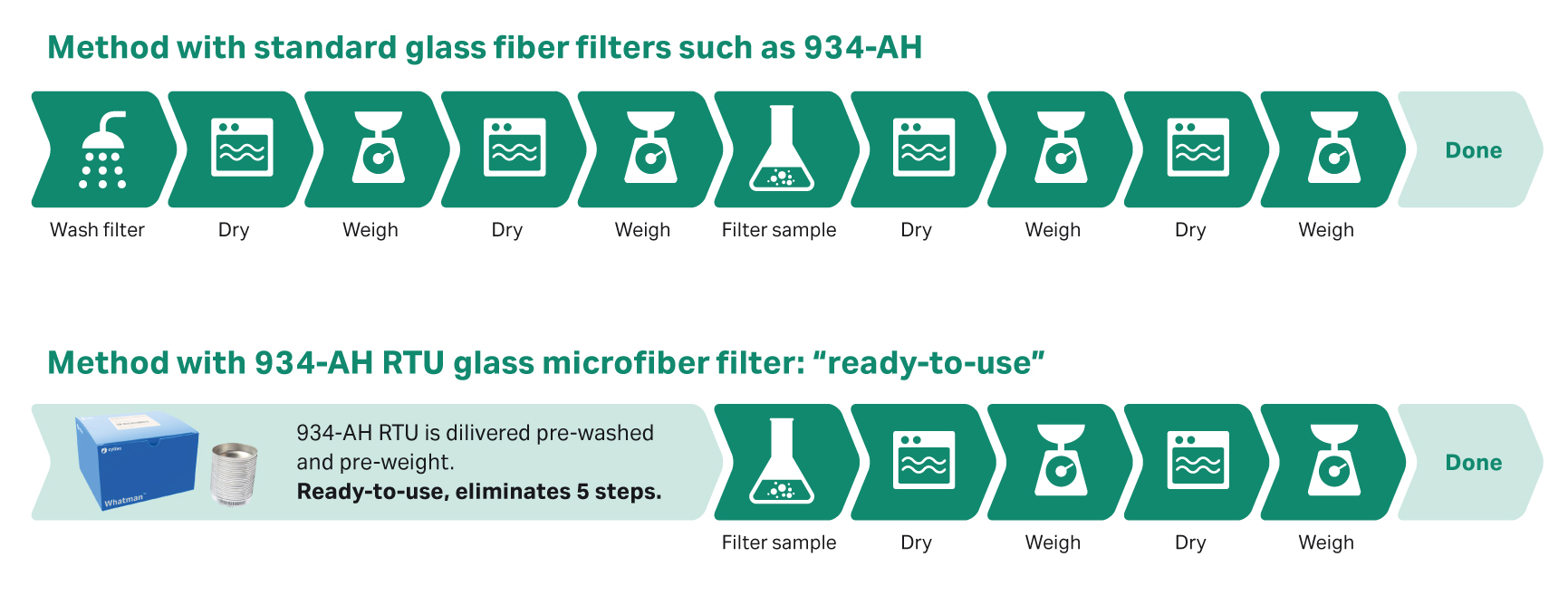

With seven steps in the filtration process, TSS testing is not only time-consuming, but also leaves too much room for human error. Add in the high volume of samples many labs must test daily, and the need for efficiency is clear.

That’s where the Whatman™ 934-AH™ RTU (ready-to-use) filters by Cytiva come into play. These filters have been pre-treated to various degrees in accordance with US Standard Method 2540, saving time and costs compared to untreated filters. And with fewer steps in the filtration process, there is less room for human error, increasing confidence in the testing results.

Each pretreated filter comes in an aluminum pan with the filter weight clearly noted, and each pan has its own unique barcode that can be used to find documentation of the filter weight on the Cytiva website. Each box of 934-AH™ RTU filters also has a barcode that can be used to download the weights of all filters from that box to support regulatory record keeping.

By implementing the 934-AH™ RTU into the TSS testing workflow, wastewater testing labs can process a high volume of difficult samples with more accuracy and free up precious time to tackle other vital tasks around the lab. Most importantly, lab managers and technicians can accomplish the main goal of ensuring the safety and purity of the waterways.

Ready-to-use Whatman™ GF/C™ filters, which align with EN872, are also available. Refer to the related products below for the full list of standard (non-RTU) and ready-to-use products.

Try our Whatman™ Filter Selector App to find out if you are using the most appropriate filtration solution for your samples. To discuss any challenges you are facing, please contact Cytiva's Scientific Support.

Watch our 934-AH™ filter paper demonstration to learn more.