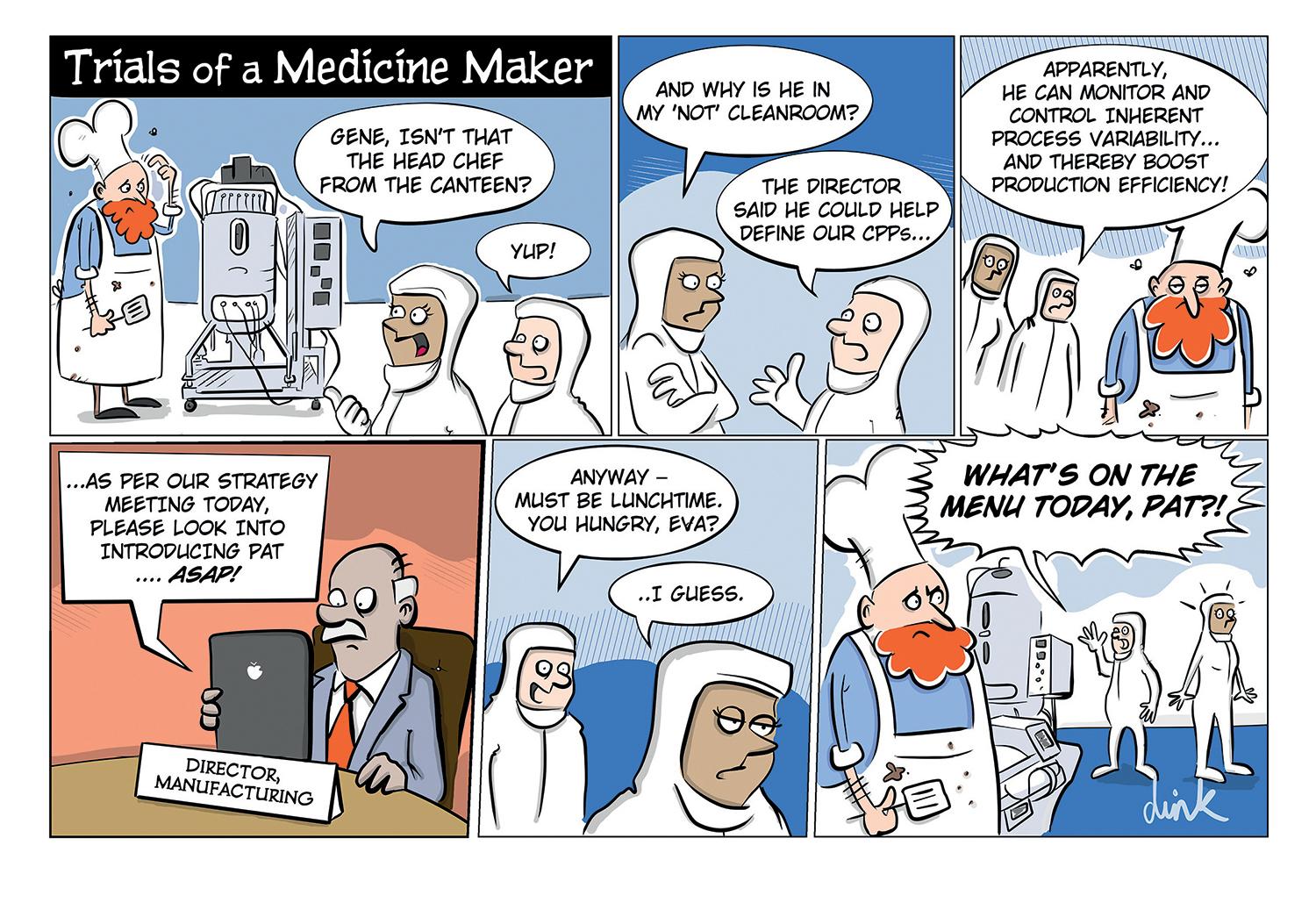

Comparing kitchens to cleanrooms might seem strange. But, as medicine makers Gene and Eva discovered, process analytical technologies (PAT) can bring success in both places. Here’s why.

Well…I’m not sure I would let Pat into my cleanroom. But getting the head chef to improve the bioprocess recipe is not that farfetched. Just think of the similarities. In both cooking and bioprocess optimization, raw materials and critical parameters play an important role.

Too much flour, not enough sugar, and cooking at the wrong temperature probably results in a lousy cake. The same goes for bioprocessing. Tight control over your raw materials, systematically following the recipe, and process analytical technologies (PAT) can bring you a better-quality product and more reproducible results.

Why invite PAT into your cleanroom?

In a recent interview with The Medicine Maker, Patrick Guertin, Global Technical Manager for Cytiva, discussed challenges associated with scaling up a process. He highlighted the everyday importance of PAT in biomanufacturing:

‘I’ve seen a lot of companies with limited understanding of their process and insufficient relative data, which can lead to problems when moving from the lab to the commercial scale. You need to be asking, how are you controlling the critical process parameters? How does the process impact the molecule? And how can you align yourself with state-of-the-art technologies, and use them for the right processes?’

So, will you invite PAT into your cleanroom?