Prepacked chromatography columns in biomanufacturing can save time, but also present concerns related to delivery lead times, capacity, and operational cost. Here are three ways to mitigate these concerns.

1. Manage delivery times with standard components and planning

Today, the majority of single-use equipment is customized to fit user-specific processes, affecting delivery lead times, unit cost, and performance robustness. One way to address these challenges is to choose standardized, configurable columns.

Standardized columns use verified components and manufacturing methods, so they can use multiple components for different column diameters and bed heights. Using standard components allows shorter delivery times and opportunities for better planning of both cash flow and production campaigns.

Moving from occasionally replacing the resin to replacing the whole packed column for each campaign might add complexity to delivery lead times. Continuous forecasting with suppliers and/or setting up a dedicated safety stock at the supplier’s site will help minimize risks for delayed deliveries.

2. Match column capacity to your bioreactor harvest

Column diameter, bed height, and resin characteristics determine total column capacity. That is, for a given diameter, the bed height might need to be varied to optimally accommodate different upstream product titers.

Increasing the bed height from 20 to 25 cm can increase the total column capacity by 25%. The increased bed height means you might be able to process your total harvest in fewer cycles, ultimately reducing your process time (Table 1).

When scaling, however, you should keep the loading residence time constant by adapting the volumetric flow (Fig 1).

Table 1. The amount of mAb that a ReadyToProcess column with 359 mm i.d. can process in a single cycle (data for two different chromatography resins packed at three bed heights)

Bed height (mm) | Load (g/L) | Processed mAb (g/cycle) | ||

| MabSelect SuRe LX | MabSelect PrismA | MabSelect SuRe LX | MabSelect PrismA | |

| 150 | 47 | 63 | 705 | 945 |

| 200 | 47 | 63 | 940 | 1260 |

| 250 | 47 | 63 | 1175 | 1575 |

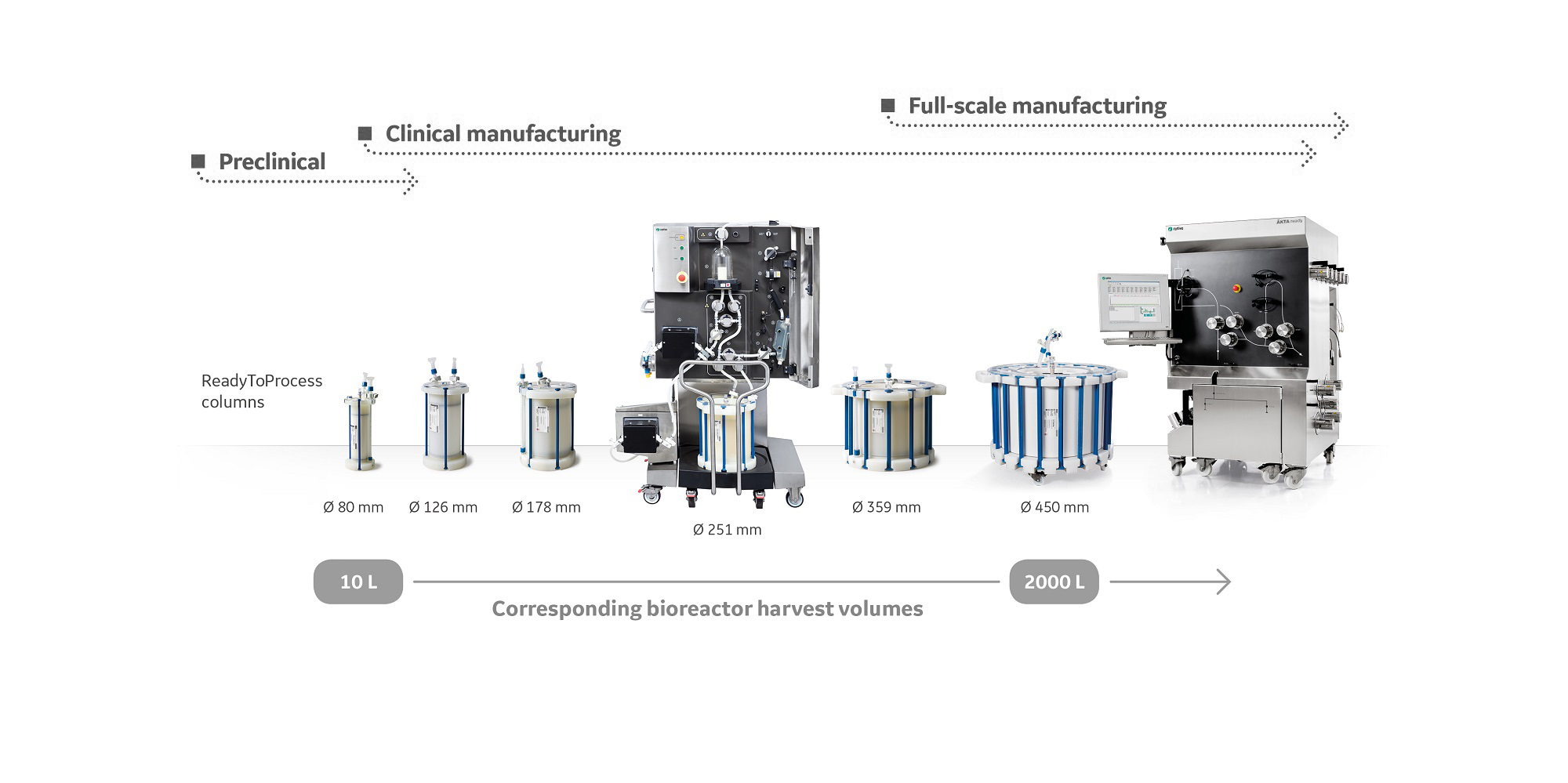

Fig 1. ReadyToProcess columns can be used with ÄKTA ready and ÄKTA ready XL chromatography systems. Consistency in column geometry allows for convenient scaling of ReadyToProcess columns from 80 to 450 mm in i.d.

3. Optimize process economy by column reuse

Most of the cost of a prepacked column comes from the chromatography resin. But resins can be used for up to several hundreds of cycles, justifying their cost per volume.

Reusing the column could significantly improve process economy. However, reuse of the disposable column requires a stable and validated column bed to ensure a consistent performance over multiple process cycles.

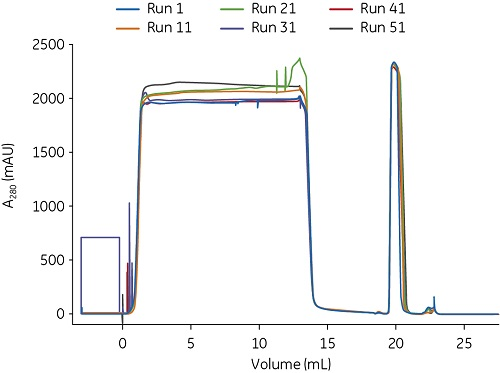

A study with real harvest feed shows that the disposable ReadyToProcess columns can be used for up to 50 cycles with maintained performance (Fig 2), making these columns a viable option for large-scale regular manufacturing.

Fig 2. Overlay of chromatograms from runs 1, 11, 21, 31, 41, 51 of repeated mAb capture cycles using the ReadyToProcess MabSelect SuRe LX 1 L column.

Learn more

Learn more about how ReadyToProcess columns can address your needs in clinical and regular manufacturing.