Developing a process or looking for a clone of interest often requires screening large numbers of samples. Many analyses require purified protein, and substantial hands-on time might be allocated to this task. In this post, Penny describes how she worked with a customer to develop a solution to increase throughput of mAb purifications, decreasing hands-on time.

Six months ago I got a request from a lab that uses several of our ÄKTA systems to purify monoclonal antibody (mAb) candidates for screening and characterization. This very busy lab wanted to be able to do more than 50 two-step (two-dimensional) purifications unattended without the need for going back to their ÄKTA system. This capability would allow staff members to spend their time on other critical work.

Here I will describe how we modified an ÄKTA pure system and developed an automated two-step purification method and scouting protocol in our labs at GE. The customer then optimized the two-step purification method for his mAb samples.

An off-the-shelf solution

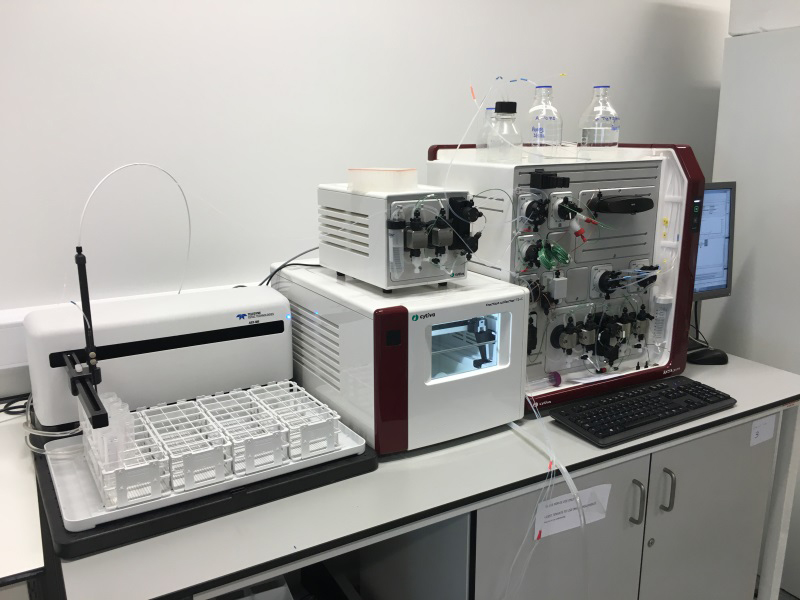

Building upon previous work, we connected an autosampler (ASX-560, Teledyne CETAC) to an ÄKTA pure chromatography system via an I/O box. Connection to the box allows the ÄKTA pure to send digital signals to the autosampler.

ASX-560 (left), sample pump (middle top), fraction collector (middle bottom), ÄKTA pure 25 system (right).

Protocol for 2-D purification

We connected the ASX-560 sampling line to the S1 position on the ÄKTA pure’s sample inlet valve. The simple method we created is a standard two-step process with a capture chromatography step followed by a desalting column. To facilitate method development, we used HiTrap Capto S followed by HiTrap Desalting, with a BSA test sample. After development and testing in our lab, the customer further developed the method by changing the first column to a HiTrap MabSelect SuRe column. Here is an overview of the final method.

To begin, a MabSelect SuRe column is equilibrated and then the first sample is directly loaded onto the column using the ÄKTA system’s sample pump/sample inlet valve. End of loading is triggered by the air sensor in the sample inlet valve. The buffer line on the sample inlet valve is selected, and the sample remaining in tubes is loaded onto the column. Then the autosampler returns to the rinse station, which is filled with phosphate-buffered saline (PBS). An S1 sample pump rinse with PBS clears the line of air. After washing, the MabSelect SuRe column is eluted and the eluted peak diverted via a UV watch command to a loop. The eluted sample is then loaded from the loop onto an equilibrated HiTrap Desalting column. Finally, the desalted peak is collected in the fraction collector.

A scouting protocol is set up in the ÄKTA pure’s UNICORN software to repeat this process, matching the number of samples loaded in the autosampler. A cleaning-in-place (CIP) procedure is performed between each sample to avoid cross-contamination.

Results from initial method development in our GE lab

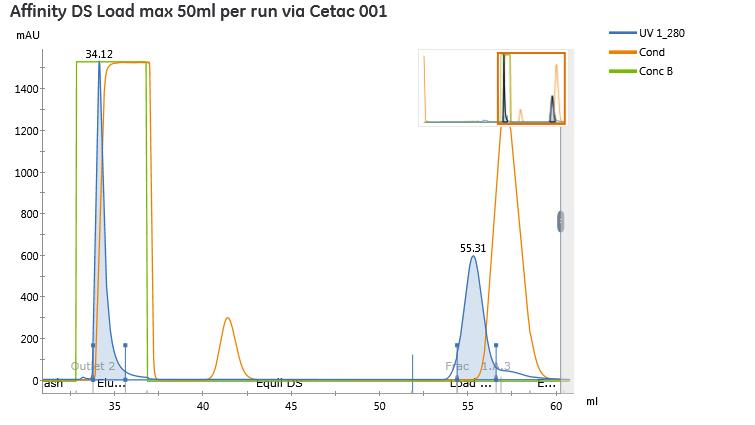

Initial method development was performed at GE. An ÄKTA pure system was connected to an ASX-560 fraction collector as described previously, and an automated two-step purification method was developed with ion exchange chromatography followed by desalting. Results in the following chromatogram and table are for a BSA test sample (3 mg in 50 mL) using a 4 mL/min flow rate for the 1 mL HiTrap Capto S column and 5 mL/min for the 1 mL HiTrap Desalting column. The yield was 88%, based on an area under the peak calculation from UNICORN 7.

| Peak | Retention (mL) | Area (mL*mAU) | Area (%) | Fraction(s) | Volume (mL) | Conductivity (mS/cm) |

| Peak A (first peak) | 34.125 | 839.3 | 53.17 | Outlet 2 | 1.83 | 64.59 |

| Peak B | 55.308 | 739 | 46.83 | Frac - 1.A.2 | 2.211 | 8.94 |

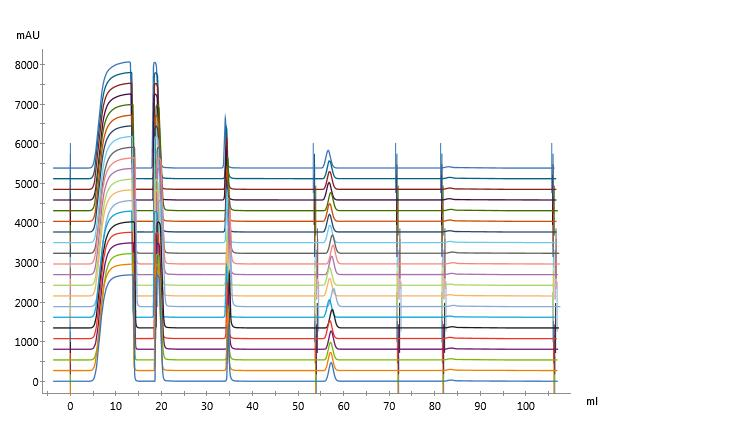

Results from a scouting run at GE

A 21-sample scouting run was performed. The A280 results are shown in the following overlay chromatogram. The first peak, Peak A, is the flowthrough from the HiTrap Capto S column; Peak B is the eluted protein; Peak C is the desalted protein; and Peak D is a result of the CIP procedure. The cycle time was 30 min.

Customer results

The customer further developed the method for mAb purification by swapping out the HiTrap Capto S column for a HiTrap MabSelect SuRe column. Some of the customer’s development data is published in a Teledyne CETAC application note, High throughput automation of the ÄKTA pure 25 via the ASX-560.

Based on the customer’s positive outcome with the modified ÄKTA system set-up and developed method, he is looking forward to doing dozens of mAb screening preps unattended without the need for returning to his ÄKTA pure system after selecting the Run button.

Please share your comments or questions below.