Controlled perfusion in a closed, single-use bioreactor can cut the complexity from your cell culture expansion process, making it possible to go from seed train to full production in a single, cost-effective step.

Simplifying the cell expansion journey

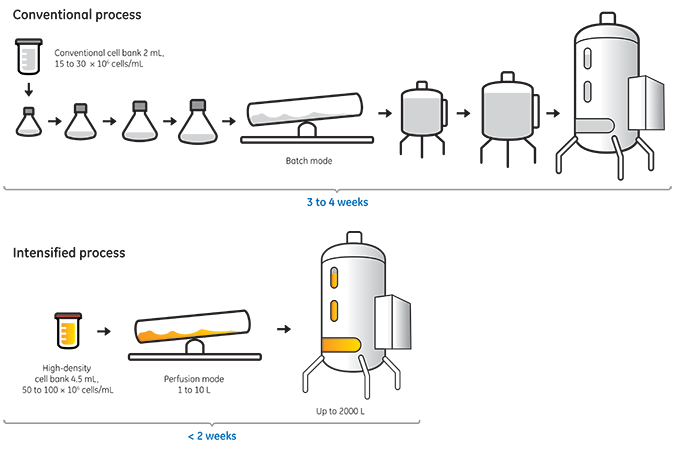

Picture a seed train, and you probably envision a sea of progressively larger bioreactors that require preparation before use. In a typical process, these bioreactors are needed to increase the number of viable cells until the culture can be transferred to your target volume production bioreactor.

Most seed trains involve between 5 and 10 steps. Operators perform checks at regular intervals by moving the shaker flask to a biosafety cabinet and counting the number of cells in the culture. When ready, the culture is transferred to progressively larger vessels. At each step, the potential for contamination is real. It’s a process that’s ripe for simplification.

Perfusion with the WAVE 25 bioreactor

What if the multi-stepped shaker flask and bioreactor process could be replaced by a single bioreactor? The ReadyToProcess WAVE 25 bioreactor has been successfully used to expand CHO (Chinese hamster ovary) cells from a single vial of high-density cell bank to a 2000 L production bioreactor, and even provide multiple new cell bank vials along the way.

Because the WAVE 25 and Cellbag are a closed system, there is no need for manual changeovers or biosafety cupboards. All the operator needs to do is connect a needleless syringe to the Cellbag’s port to remove cells for counting.

Accuracy and control

To maintain healthy, viable cells in culture and keep them at an exponential growth rate, it’s crucial to be able to control critical variables such as pH, DO (dissolved oxygen), and motion. The WAVE 25 system uses a sophisticated range of sensors and automated software to keep these and other factors in the optimal ranges. The system can be pre-programmed according to a defined protocol, so it’s very suitable for reproducing succesful processes with a high degree of accuracy.

Once the cells have reached the required density, cryopreservation can be used to ’pause’ expansion, get the culture ready for concentration, and transfer it to a production-scale bioreactor.

One instrument, many benefits

WAVE 25 has multiple functions that contribute to upstream processes. In addition to providing seamless, single-vessel expansion via perfusion (Fig 1), the WAVE 25 system can be used to produce new cell banks thanks to its cell retention filter. By draining out medium without cycling new medium in, concentration levels can be increased up to the high density per mL required. Operators can then take aliquots of concentrated medium to cryopreserve for subsequent production or future use. No centrifugation step is required.

Fig 1. Vials from a high-density cell bank can be used for direct inoculation of a small bioreactor culture, eliminating the need for shake flask operations in the immediate post-thaw expansion phase. The use of perfusion in the bioreactor stage allows cells to stay in exponential growth phase throughout the entire culture, for high final viable cell density and cell viability. By such a procedure, an N-1 culture at 10 L scale can be used to seed a production culture with a final volume of 2000 L.

Savings and economies

The benefits of replacing multiple flask-based steps with a single-use bioreactor are many. There are fewer consumables involved, a smaller physical footprint for the work, and less demand on operator time. The process also shortens the time horizon, typically trimming a process that would be expected to take over 2 weeks down to around 10 days. Given that the cell doubling time is fixed by the natural properties of the cells, this time saving can be attributed to simplification and streamlining of the process.

All gain, no compromise

The cells produced by the simplified process proved to be healthy, meeting the experimenters’ targets of > 95% viability. Their growth after revival from cryopreservation was comparable to conventional cell bank performance.

See the complete method and results in our application note.

Download the full paper (PDF)

A culture of innovation

Advances like this arise as a result of continual experimentation, curiosity, and knowledge-sharing. This is just one example of how we continually iterate and improvie products and processes based on what we learn. We enjoy a culture of collaboration, both within Cytiva’s specialist teams, and beyond them, by working collaboratively with our customers and collaborators.

The Fast Trak program has been set up to support our customers and foster productive working relationships between our experts and yours. By sharing data and process design challenges with us, customers benefit from our expertise, while simultaneously adding to it so that in the future, we can make ever-greater steps forward.

Related information

Learn more about the feasibility of monoclonal antibody (mAb) production in fed-batch processes using the single-use Xcellerex XDR-200 stirred-tank and ReadyToProcess WAVE 25 rocking bioreactor systems.