The power number is an important parameter when designing a mixing process for process scale-up. The Xcellerex™ magnetic mixer is a single-use mixing system incorporating a bottom-mounted magnetically driven Rushton-type impeller capable of providing efficient high-torque mixing for powder-liquid and liquid-liquid mixing applications. The impeller rides on a low-friction, inert bearing assembly.

Introduction

The power input (Pinput) is the power transferred to the fluid by the impeller per unit of volume (V in m3) (Eq. 1).

The power number (Po) is the link between the power delivered by the impeller to the fluid. Ignoring the friction in the drive and bearings of the impeller enables us to calculate the power number from the known parameters (Eq 2), where Po is the power number in W/m3, M is the torque in Nm, N is the speed in rev/s, and d the impeller diameter in meters (m).

Our test generated multiple power numbers depending on the mixing speed and the fill level.

Materials and methods

We modified the drive of an Xcellerex™ magnetic mixer to incorporate a Datum Electronics RS425 torque sensor. We then mixed water at different speeds and fill volumes in 2000 and 3000 L mixing tanks as summarized in Table 1. For each of the performed experiments, the power number was calculated based on the moment the torque was stabilized after reaching the target mixing speed. The calculation was done by subtracting the blank torque (torque required to mix in the absence of liquid in the mixer) from the measured torque.

Table 1. Experimental conditions

| System description | Tested fill volumes (L) | Tested mixer speed (rpm) |

| 2000 L | 500 (25%), 1000 (50%), 1500 (75%), 2000 (100%) | 100, 200, 300, 310 |

| 3000 L | 750 (25%), 1500 (50%), 2250 (75%), 3000 (100%) | 100, 200, 300, 310 |

Results and discussion

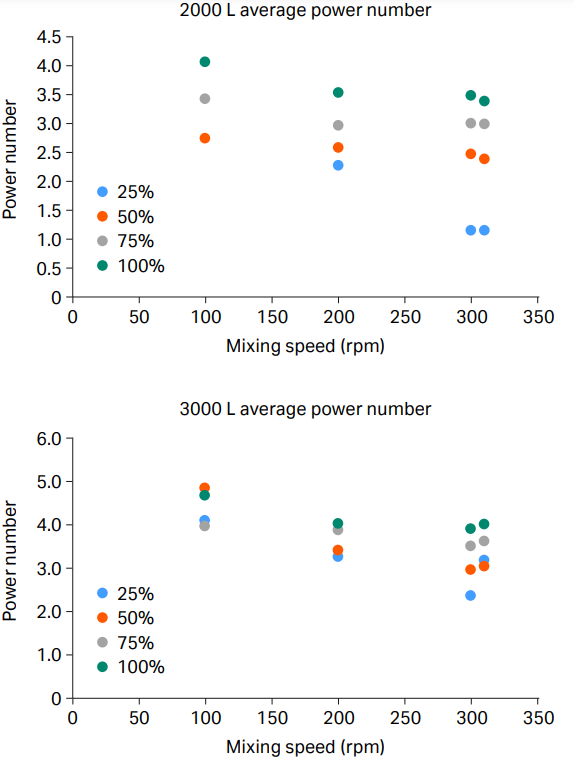

Figure 1 presents the calculated power number at each tested fill volume, and mixing speeds tested in both the 2000 and 3000 L mixing tanks. Table 2 reports the average power number at each fill level at the tested mixing speeds. In both tanks the power numbers increased with the fill level. In the 2000 L tank, the power numbers decreased with an increasing mixing speed, while in the 3000 L tank they decreased in the 100 to 200 rpm range, then flatened out for mixing speeds above 200 rpm.

Fig 1. Average power number for Xcellerex™ magnetic mixer in 2000 and 3000 L mixing tanks.

Table 2. Average power number at various fill levels and speeds.

| Fill level | 100 rpm | 200 rpm | 300 rpm | 310 rpm | |

|---|---|---|---|---|---|

| 2000 L | 25% | 2.7 | 2.3 | 1.1 | 1.1 |

| 50% | 2.7 | 2.6 | 2.5 |

2.4 | |

| 75% |

3.4 | 3.0 | 3.0 |

3.0 | |

| 100% |

4.1 | 3.5 |

3.5 |

3.4 |

|

| 3000 L | 25% |

4.1 | 3.3 | 2.4 |

3.2 |

| 50% |

4.8 | 3.4 |

3.0 |

3.1 | |

| 75% |

4.0 | 3.9 | 3.5 |

3.6 | |

| 100% |

4.7 |

4.0 | 3.9 |

4.0 |

Table 3 reports the average power input at the maximum mixing speed for both tanks at a fill volume of 100%. There was a decrease in the power input due to the power being dispersed further with an increase in volume.

Table 3. Average power input (W/m3) at maximum mixing speed at 100% fill volume.

| 2000 L | 3000 L | |

| Maximum speed | 310 rpm | 310 rpm |

| Average power input (W/m3) | 88.6 | 70.2 |

Conclusion

Power numbers are an important peremeter for process scale-up and designing a mixing process. We have determined the power number at various mixing speeds and fill levels for Xcellerex™ magnetic mixers. We have shown that the power input of the Xcellerex™ magnetic mixer impeller at the maximum fill level and speed of 310 rpm was 88.6 W/m3 for 2000 L tank and 70.2 W/m3 for the 3000 L tank. These high power values allow for strong vortex formations which are effective for various powder dissolution applications at large-scale.