Sterilizing grade filter performance with high concentration drug products

A throughput benchmarking study with Supor™ Prime membrane

I. Introduction

As the development and manufacturing of biologics for subcutaneous injection grows, new challenges arise in filtration processes. These processes play a crucial role in contamination control during drug substance production, as well as for sterility assurance during the final drug product filling.

When antibody concentrations exceed 100 g/L, fluid viscosity markedly increases. Viscosities of high concentration feeds typically range from 10 to 30 cP compared to just 1 to 5 cP for formulations with concentrations of less than 30 mg/L. This increase in viscosity leads to a reduction in the typical flowrates achieved by any given filter selection. These higher concentrations may also increase filter fouling which reduces the average process flow rate further. Consequently, larger filters are required to process the batch and to maintain targeted flow rates during the final filtration of drug substance and drug product. These larger filters can lead to greater unrecoverable volumes of high-value drugs due to the hold-up volumes of the filter and associated filtration system. In addition, larger filters also have an environmental impact such as greater consumption of water during processing, an increased mass of polymer and corresponding increased weight during shipment and disposal. Such factors are increasingly common contributors to the filter selection criteria.

When reviewing filter performance, relative flowrates may be indicated by a comparison of water flowrates published by the filter manufacturer. However, this alone is not an accurate predictor of in-process performance when a degree of filter blockage is expected. In these instances, filter throughput performance can be evaluated with simple small-scale filterability studies using a fluid sample that is representative of the process material. The volume of material available during development process restricts opportunities for extensive filter benchmarking even when using predictive modelling to reduce the fluid volumes required. This can result in suboptimal filter selection.

In this application note, we compare the throughput performance of our Supor™ Prime filter membrane with other sterilizing grade membranes in a range of moderate-to-high concentrations of monoclonal antibodies (mAbs) and immunoglobulins (IgG). From this, we showcase the performance of Supor Prime filters and the potential impact their selection can have on filter sizing.

Read on to learn how the right filter selection can optimize your process and foster success in your biologics production journey.

II. Test method

The membranes used in this study are shown in table 1.

Table 1: membranes used in this study and published specifications for related filters

| Membrane tested | Manufacturer | Material of construction | Rating | Area per 254 mm (10 in.) filter (m2) | Water flowrates per 254 mm (10 in.) filter (L/min/100 mbar) |

| Supor Prime | Cytiva | Polyethersulfone | 0.2 µm | 1.34 | 18 |

| Express® SHC | Merck Millipore EMD | Polyethersulfone | 0.2 µm | 1.0*† | ~8† |

| Sartopore® Platinum | Sartorius KGa | Polyethersulfone | 0.2 µm | 1.0‡ | ~8‡ |

* High area variant

† Lit. No. MK_PG1284EN Ver 2.0 39880 03/2022

‡ Publication No.:SPK2157-e | Status: 08 | 01 | 2022

The throughput performance of each membrane was evaluated in up to 17 fluids with antibody concentrations ranging from 70 g/L to 220 g/L. Of these fluids, 14 were supplied by end-users and a further 3 were tested from a bank of internal test fluids including formulations derived from Rituximab and Trastuzumab excreting cell lines. Details of each fluid used in the study are shown in appendix 1.

Throughput testing

Filterability tests were conducted using the most suited small-scale device available given the volume of fluid available for each test. Test device areas and descriptions can be found in appendix 1.

Tests were performed under constant pressure conditions with each membrane tested using the same feed material. The filtration was performed at a constant pressure of 0.69 bar (10 psi) with the decline in flowrate being monitored for each membrane using an automated data collection system.

Throughput for each membrane and fluid combination was calculated from these data using the gradual pore plugging model[ref] and reported as the calculated volumetric throughput at 90% flux decay (V90) in L/m2. All subsequent analyses assume the stated area of the device used is accurate and scales linearly based on the quoted area or larger devices.

III. Results

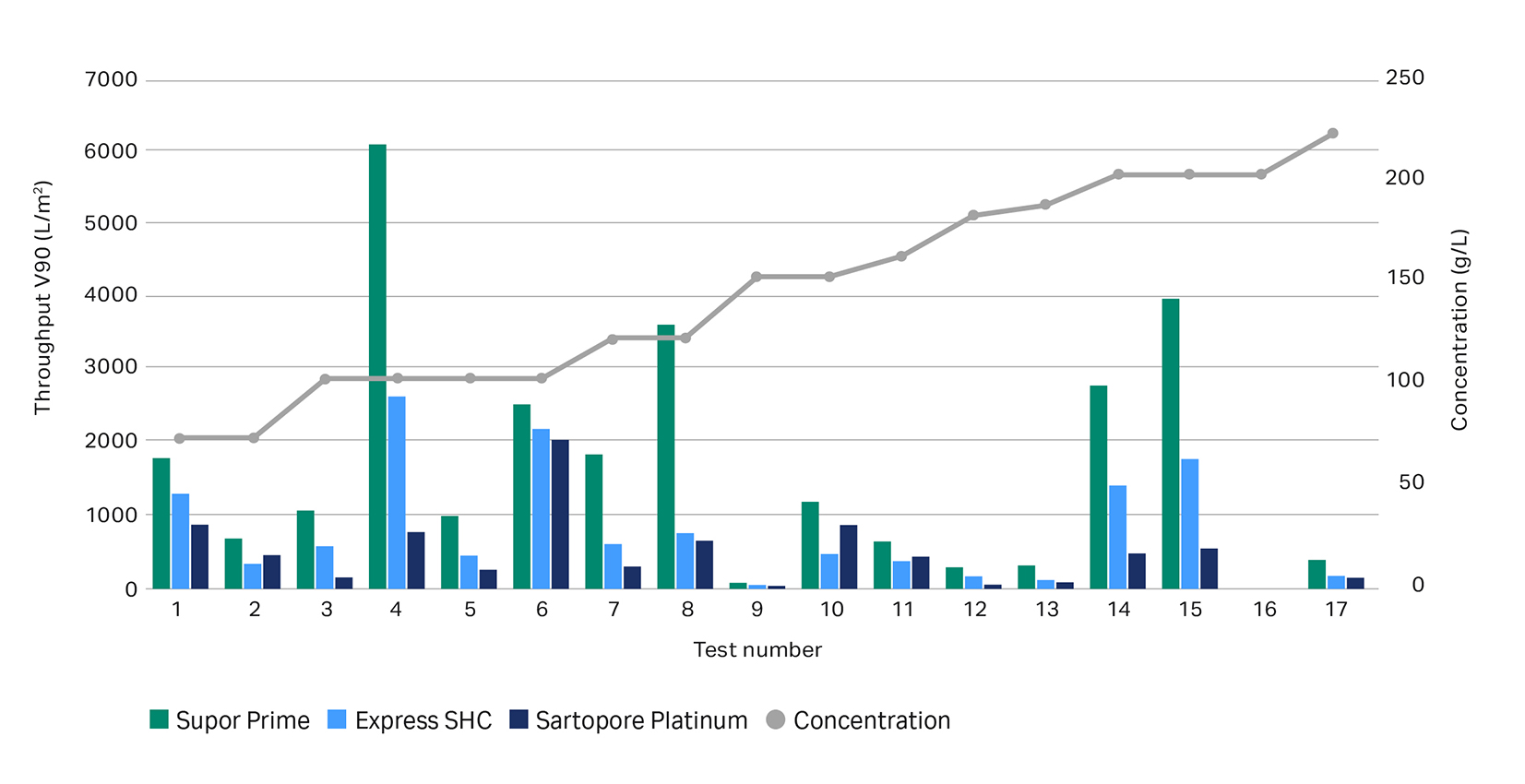

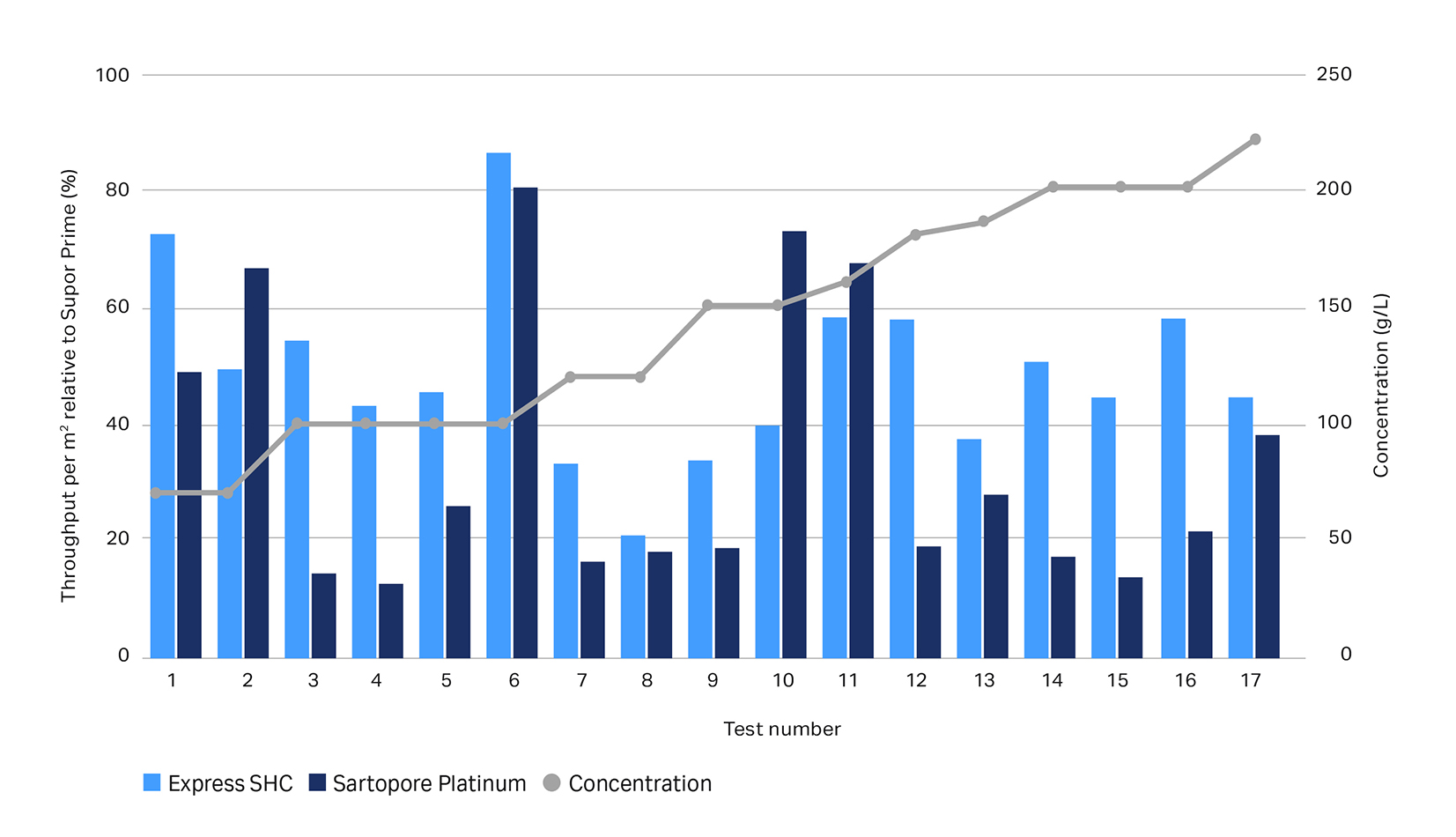

The calculated throughput (V90) for Supor Prime membranes varied significantly, from ~ 25 to ~ 6000 L/m2, across the range of fluids in this study (fig 1). The relative performance of Supor Prime membrane in each of the fluids in this study is also shown in figures 2a and 2b.

Fig 1.Throughput performance per m2 of membrane. Each data point is in n=1 tested in parallel with other filters. Individual feed comparisons may vary upon replication.

Fig 2a. Relative performance.

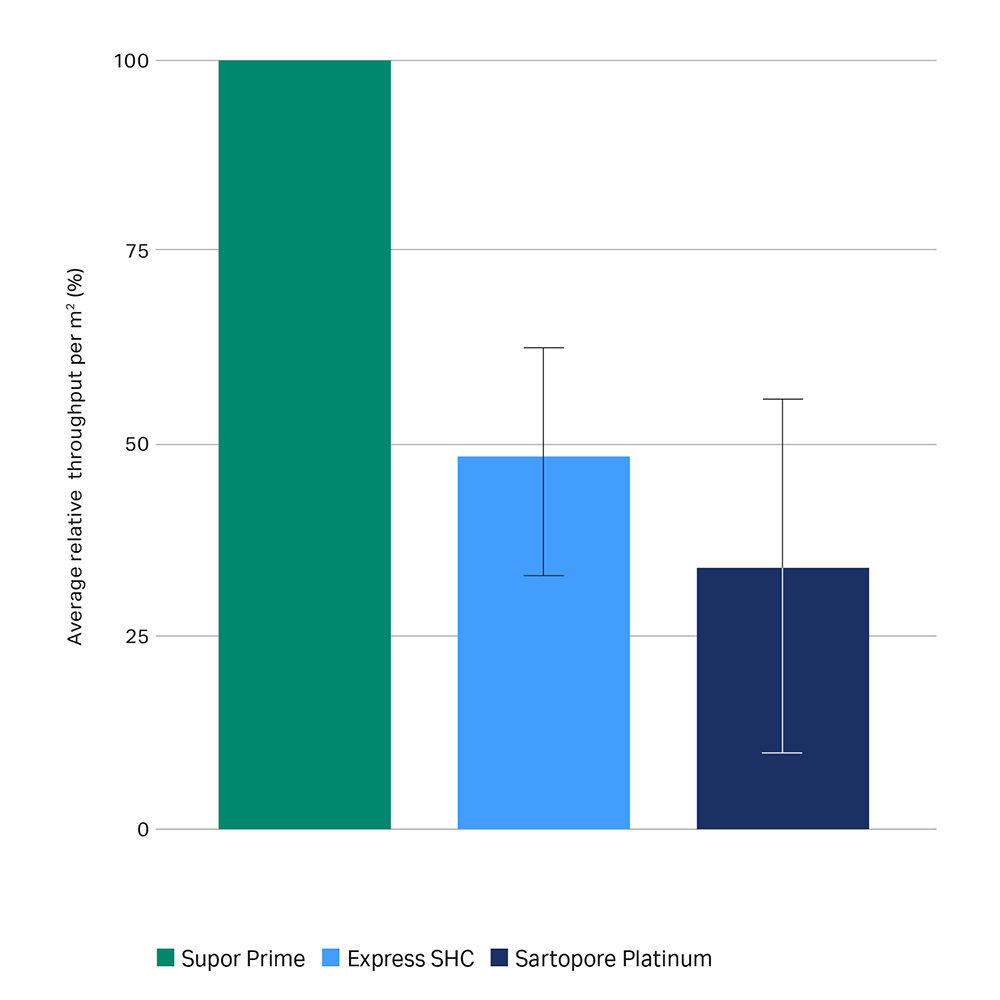

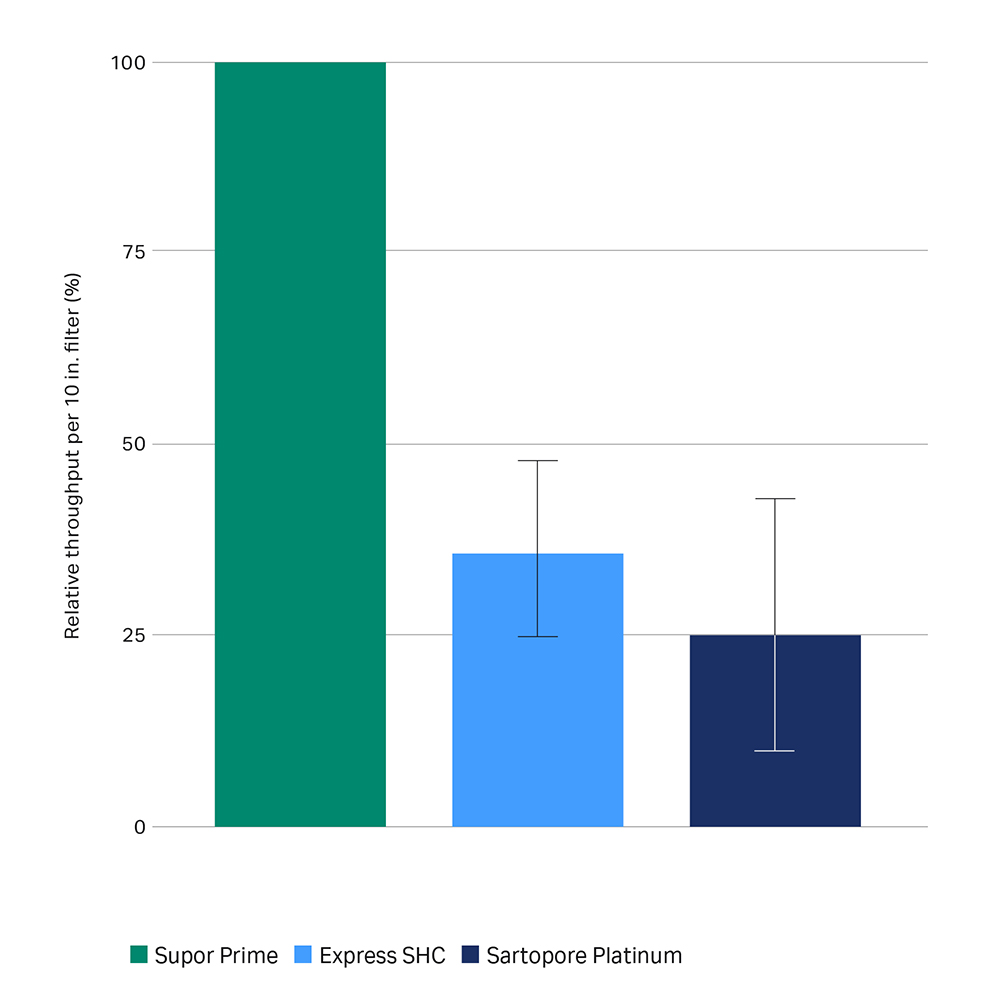

Fig 2b. Average relative throughput performance per m2 of membrane compared to Supor Prime membrane. Error bars represent one standard deviation of the mean. The difference in the mean is highly significant (p<0.01) for both Express SHC (n=17) and Sartopore Platinum (n=17) using a two-tailed paired Student's t-test. Results for individual feeds will vary.

IV. Analysis

The wide range of throughput results obtained for all membranes tested highlights the importance of throughput testing to establish the likely performance for each process fluid. The relative membrane performance is an indicator of relative filter performance however the area of the filter format should be accounted for before making a direct comparison.

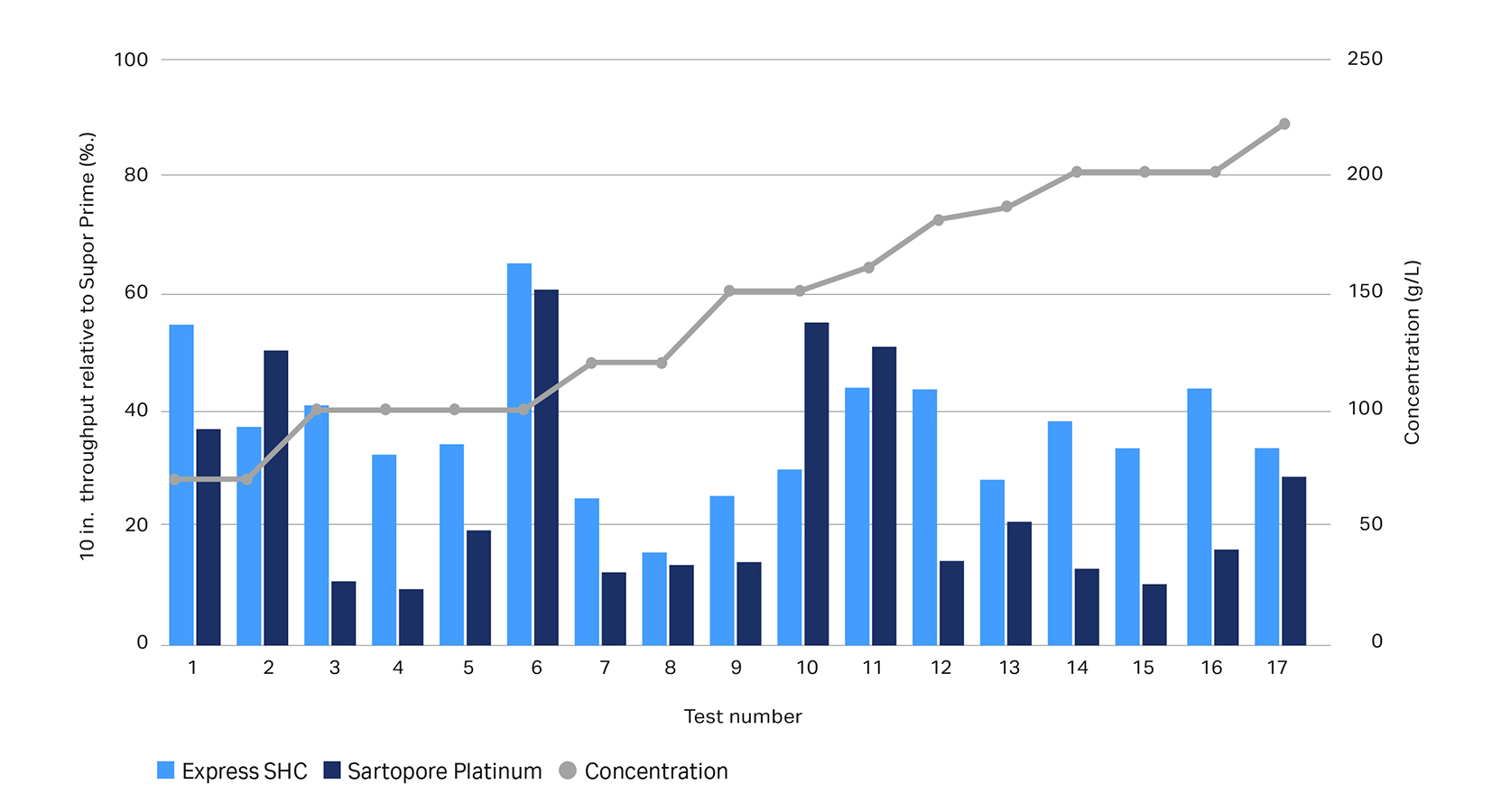

The data shown in figures 3a and 3b is adapted from data shown in figure 2a and 2b to account for the different filter areas. In this scenario the higher area of Supor Prime in this format extends the average performance margin of Supor Prime filters compared to other filters in this study.

Fig 3a. Relative throughput performance per 254mm (10 in.) filter. Each data point is n=1, tested in parallel with other filters and scaled up using published filtration areas. Individual feed comparisons may vary upon replication.

Fig 3b. Average relative throughput performance per 254 mm (10 in.) filter compared to Supor Prime filters. Each data point is scaled using published filtration areas. Error bars represent one standard deviation of the mean. The difference in the mean is highly significant (p<0.01) for both Express SHC (n=17) and Sartopore Platinum (n=17) using a two-tailed paired Student's t-test. Results for individual feeds will vary.

Impact of filter performance on process filter sizing

Filter sizing needs to consider the critical process parameters that must be achieved during each filtration operation. Bulk filtration of drug substance is typically driven by the capacity of the filter whereas the final filtration of drug product may also need to consider a minimum acceptable average flowrate. In the final filtration of drug product, blockage is often reduced due to previous filtration of the fluid however, this low-fouling characteristic should not be assumed. Storage, transportation or any freeze/thaw process may generate multimers and aggregates that may increase filter blockage despite previous filtration.

Sizing example

The maximum volumetric capacity is typically the filter performance attribute that influences filter sizing the most. This is m in applications where the bulk of the fluid is processed without a time limitation. This includes most bulk filtration processes immediately prior to bulk filling in drug substance production.

The following example uses the mean throughput and flowrate performance from this dataset based upon a typical relative performance shown in figure 2a. The impact of the effective filtration area of the targeted filter configuration is also included to represent a real-world filter sizing exercise, including a nominal safety margin of 50%.

Table 2: impact of throughput of filter sizing

| Filter membrane | Throughput, V90 (L/m2) | Minimum filter area for 250 L batch† (m2) | Recommended filter size‡ | Recommended filter device area (m2) |

| Supor Prime | 1000 | 0.38 | 1 × 5 in. | 0.63 |

| Express SHC | 485 + 148 = 633* | 0.59* | 1 × 10 in. | 1.0 |

| Sartopore Platinum | 340 +230 = 570* | 0.65* | 1 × 10 in. | 1.0 |

* Calculated using average relative throughput performance (mean + 1σ) shown in figure 1b

† Including 50% area safety margin

‡ Based on published areas of filter modules. Other filter configurations may be available.

V. Conclusion

Throughput performance varies significantly across different feed streams however, these data demonstrate a significant increase in average relative performance when compared to the other filter membranes tested.

Across the range of high concentration antibody feed streams tested ranging from 70 to 220 g/L, the average throughput of Supor Prime filters are shown to be 2 x the other filters tested.

VI. Summary

Selecting the right sterilizing grade filter for highly concentrated and viscous mAb solutions requires careful thought and consideration. Often, during process development, there's a limited amount of fluid available, making it impractical to test numerous filtration products. This limitation can lead to a risk of not including the ideal filter grade in the test panel, resulting in potentially oversized filters, and reduced yields due to the larger filter hold-up volumes of these larger than necessary filters.

This study confirms that, on average, the Supor Prime filter membrane outperforms other membranes tested with high concentration and viscous feeds. On average Supor Prime filters deliver twice the volumetric throughput, enabling operational benefits such as increased yields from smaller filters. Additional benefits such as reduced water consumption may also be realized alongside the environmental benefits of reduced shipping and disposal weights associated with the use of smaller products. Furthermore, for low fouling applications the comparatively high water-flowrate compared to similar published values indicates shorter filtration times are likely in both high and low fouling feeds.

Every process formulation comes with a unique filtration challenge. It is recommended that these should be quantified early in the process development pathway. These findings emphasize the value of including Supor Prime sterilizing grade membranes when evaluating filter options, particularly for challenging fluids such as high concentration mAbs and viscous drug formulations.

Give Supor Prime filters a try and define the difference in your process.

Know more about Supor™ Prime sterilizing grade filtersTable 3: study details and results

| Test number | Test formats† | Fluid characteristics | Throughput, V90 (L/m2) | |||

| Fluid type |

Concentration (g/L) |

Supor prime |

Express SHC |

Sartopore Platinum |

||

| 1 | A / A / A | Internal mAb | 71 | 1774.0 | 1290.0 | 870.3 |

| 2 | A / A / A | Internal mAb | 71 | 684.0 | 338.9 | 457.5 |

| 3 | A / A / A | IgG | 100 | 1062.6 | 578.8 | 154.5 |

| 4 | A / A / A | igG (prefiltered) | 100 | 6034.1 | 2611.5 | 770.1 |

| 5 | A / A / A | IgG | 100 | 990.6 | 452.0 | 258.4 |

| 6 | A / A / A | IgG (prefiltered) | 100 | 2504.1 | 2169.9 | 2022.9 |

| 7 | A / A / A | mAb | 120 | 1824.2 | 608.4 | 302.4 |

| 8 | A / A / A | mAb | 120 | 3586.2 | 755.3 | 654.5 |

| 9 | A / A / A | mAb | 150 | 81.5 | 27.6 | 15.4 |

| 10 | A / A / A | mAb | 150 | 1182.1 | 472.5 | 865.6 |

| 11 | A / B / A | mAb | 160 | 644.2 | 376.6 | 436.3 |

| 12 | A / B / C | mAb | 180 | 292.6 | 169.9 | 56.1 |

| 13 | A / A / A | mAb | 185 | 317.3 | 119.2 | 88.9 |

| 14 | A / A / A | IgG | 200 | 2760.3 | 1403.2 | 480.6 |

| 15 | A / A / A | igG (prefiltered) | 200 | 3937.6 | 1762.8 | 547.3 |

| 16 | A / A / A | mAb | 200 | 25.2 | 14.7 | 5.5 |

| 17 | A / A / A | Internal mAb | 200 | 393.3 | 175.9 | 150.5 |

| †Test format | Format description | Effective filtration area |

| A | 25 mm disk installed in Swin-Lok™ filter holder, Cytiva | 3.8 cm2 |

| B | OptiScale® 25 capsule | 3.5 cm2 |

| C | Sartoscale 25 capsule | 4.5 cm2 |