Chromatography resins have evolved to meet demands for higher productivity

As protein purification has evolved and new molecule types have come to the forefront, scientists in process development and biomanufacturing have grown to expect ever-higher productivity from their chromatography processes.

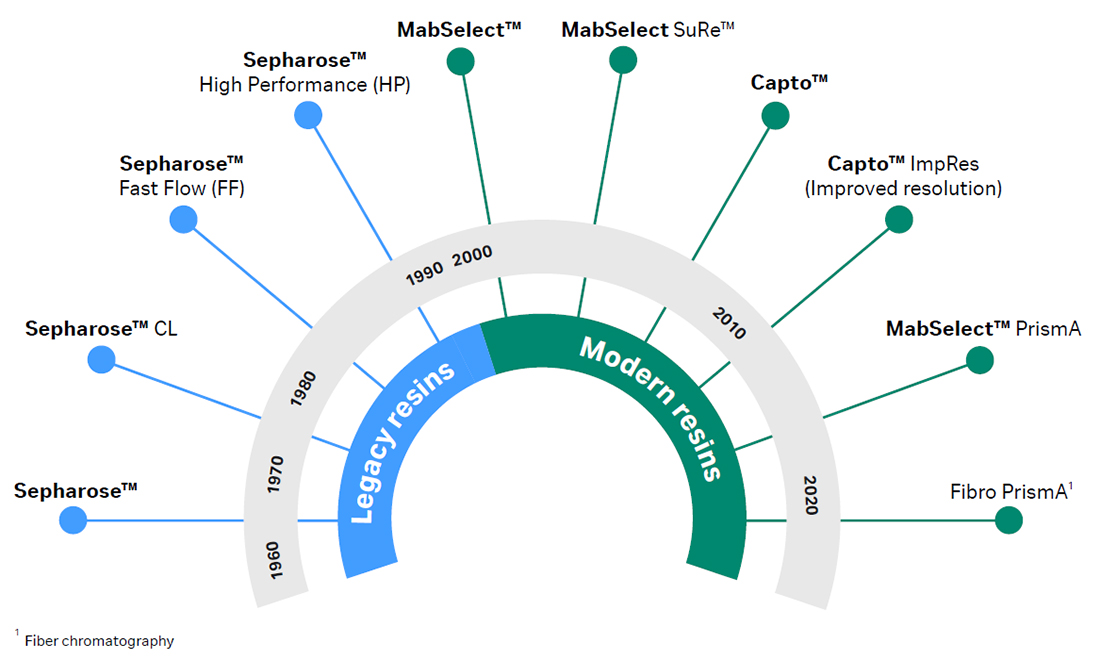

That’s why we’ve continued to innovate our chromatography resins here at Cytiva. Figure 1 shows a timeline of innovations over 60 years.

Fig 1.Evolution of Sepharose™ based resins towards modern Capto™ and MabSelect™ based resins.

You might be familiar with the ‘workhorse’ resins Sepharose™ Fast Flow and Sepharose™ High Performance that we developed in the 1980’s. Indeed, they are still used in many existing processes worldwide and are listed in many research publications. And perhaps you even use them in your daily work. But you could be missing out – on better productivity and performance.

After a decade of R&D efforts, we developed Capto™ resin and MabSelect™ resin. Both are based on high-flow agarose base matrices with significantly better flow rate performance and higher productivity than their predecessors.

Advantages of using a modern chromatography resin

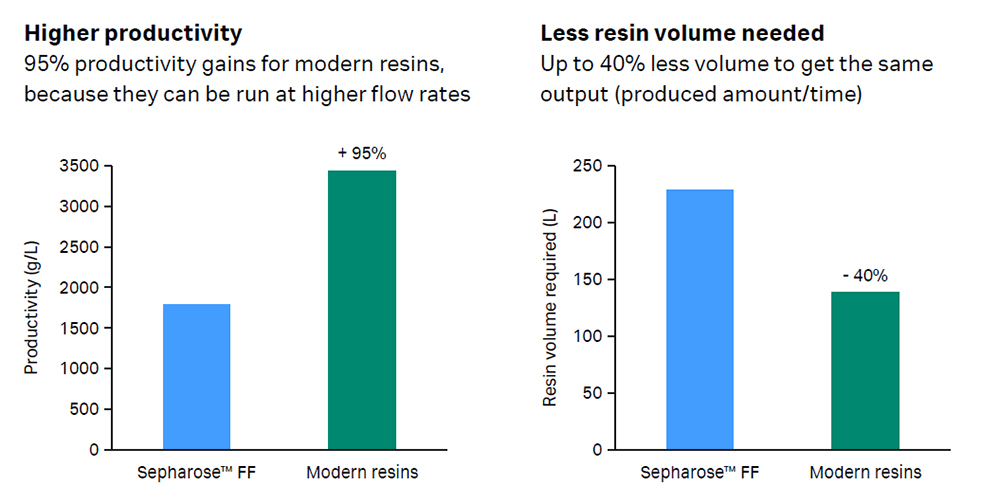

The Capto™ resin and MabSelect™ resin have two main advantages over the legacy Sepharose™ Fast Flow (FF) resin:

Check out these examples showing the benefits of switching to modern resins:

- Plasmid purification

- mAb purification: protein A capture

- mAb purification: aggregate removal via hydrophobic interaction chromatography

Advantages of using updated resins for protein A chromatography

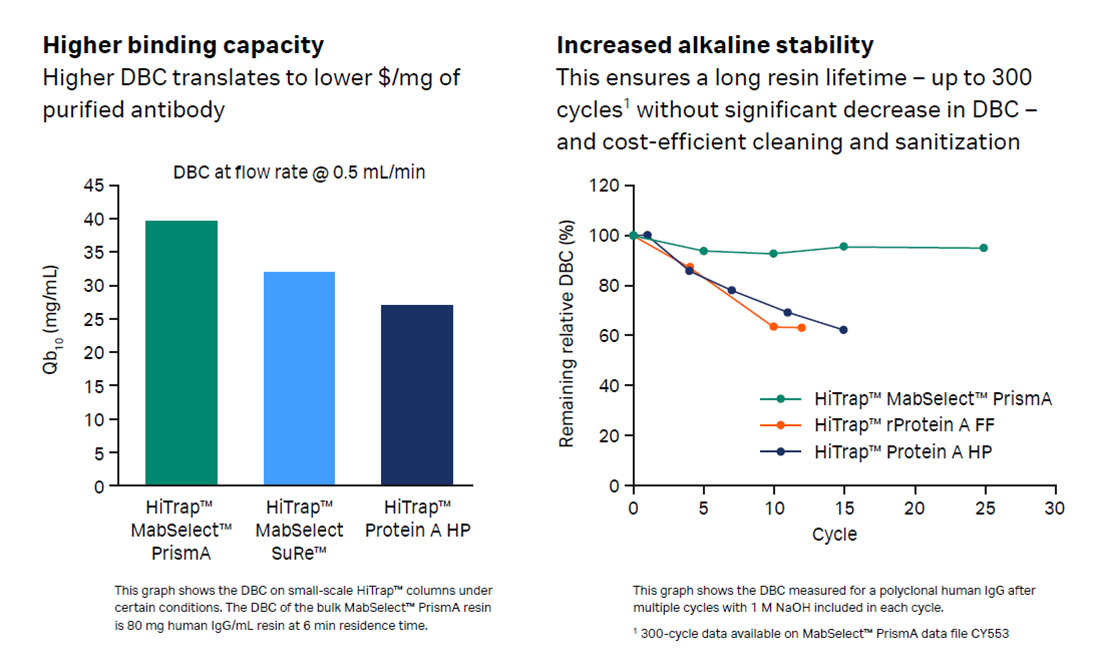

We have continued to improve protein A chromatography after transitioning our protein A resins from Sepharose™ base matrix onto MabSelect™ base matrix in 2001. Over the years we unremittingly optimized the protein A ligand to ultimately design the PrismA ligand. The resulting MabSelect™ PrismA resin offers much higher dynamic binding capacity (DBC) and alkaline stability than its predecessor products (Protein A High Performance, MabSelect SuRe™ resin, and MabSelect SuRe™ LX resin). It also has improved flow properties and mass transport.

This next-generation resin has two main advantages over its predecessors:

And if you want to purify even faster

We developed a cellulose fiber-based option that combines high flow rates with high binding capacity. Our Fibro PrismA units have the same alkaline-stable ligand as MabSelect™ PrismA. Learn more about Fibro chromatography.

How do I know which modern resin to use in my new projects?

Check this table for some suggestions. Other modern resins, including multimodal (mixed-mode) resins, are available. For an overview of all our modern resins, download this poster.

Table 1. Guidance for replacing legacy Sepharose™ based resins with the most recent resins for your new projects

| Technique |

If you’re using this resin |

Try this one |

| Ion exchange chromatography (IEX) | Q Sepharose™ High Performance (e.g., HiTrap™ Q HP column) |

Capto™ Q ImpRes |

| SP Sepharose™ High Performance (e.g., HiTrap™ SP HP) |

Capto™ SP ImpRes | |

| Q Sepharose™ Fast Flow (e.g., HiTrap™ Q FF) |

Capto™ Q | |

| SP Sepharose™ Fast Flow (e.g., HiTrap™ SP FF) |

Capto™ S | |

| DEAE Sepharose™ Fast Flow (e.g., HiTrap™ DEAE FF) |

Capto™ DEAE | |

| Hydrophobic interaction chromatography (HIC) | Phenyl Sepharose™ 6 Fast Flow (e.g., HiTrap™ Phenyl FF) |

Not sure which HIC resin to use? Try a selection kit to identify which of the following resins are best suited for your molecules. • Capto™ Phenyl • Capto™ Butyl • Capto™ Octyl • Capto™ Phenyl ImpRes • Capto™ Butyl ImpRes Indeed, the hydrophobicity of your molecule will help you choose: –Butyl, –Phenyl, or –Octyl. |

| Butyl Sepharose™ 4 Fast Flow (e.g., HiTrap™ Butyl FF) |

||

| Octyl Sepharose™ 4 Fast Flow (e.g., HiTrap™ Octyl FF) |

||

| Phenyl Sepharose™ High performance (e.g., HiTrap™ Phenyl HP) |

||

| Butyl Sepharose™ High Performance (e.g., HiTrap™ Butyl HP) |

||

| Affinity chromatography | Protein A High Performance (e.g., HiTrap™ Protein A HP) |

MabSelect™ PrismA or a fiber-based alternative, Fibro PrismA |

| Blue Sepharose™ 6 Fast Flow (e.g., HiScreen™ Blue FF) |

Capto™ Blue | |

| Heparin Sepharose™ 6 Fast Flow | Capto™ Heparin | |

| Chelating Sepharose™ Fast Flow | Capto™ Chelating | |

| Lentil Lectin Sepharose™ 4 B | Capto™ Lentil Lectin | |

| AVB Sepharose™ High Performance (e.g., HiTrap™ AVB Sepharose™ HP) |

Capto™ AVB |

Behind the curtain – insights from our R&D scientists

About our modern resins

One motivation behind creating the Capto™ and MabSelect™ products was to significantly improve the flow properties of our agarose resins. Back then, in the 90’s, agarose resins were considered as ‘soft-gels’ that did not meet new industrial requirements. The challenge was not a small one, since improving mechanical properties could mean a sacrifice in other important properties such as protein binding capacity. The aim for the new product was to improve overall process economy. After a decade of effort and creativity to optimize the pore structure and crosslinking, the first Capto™ and MabSelect™ products were launched based on the new high-flow agarose particles with significantly better flow rate performance and higher productivity, which we demonstrated. Since that day the discussion that agarose particles are inherently soft has disappeared, and the advantage of using these resins has been proven in so many large-scale biotherapeutic processes.

Tobias Söderman, Senior scientist in R&D, Cytiva

About the PrismA protein A ligand

The development of the MabSelect™ PrismA ligand has been an exciting journey. It all started back in 2012, when R&D began to study the effect of different mutations on the ligand. Eventually, it led to a project with the main purpose of stabilizing the MabSelect SuRe™ ligand further and optimizing the structure (together with the base matrix) for optimal capacity. A tremendous number of point mutations and combinations thereof were studied before choosing the final ligand. The resulting ligand surpassed our expectations, as it could withstand NaOH concentrations as high as 1 M. I am proud when I hear customers are designing-in MabSelect™ PrismA to their processes with the potential to produce large amounts of biotherapeutics.

Gustav Rodrigo, Senior scientist in R&D, Cytiva