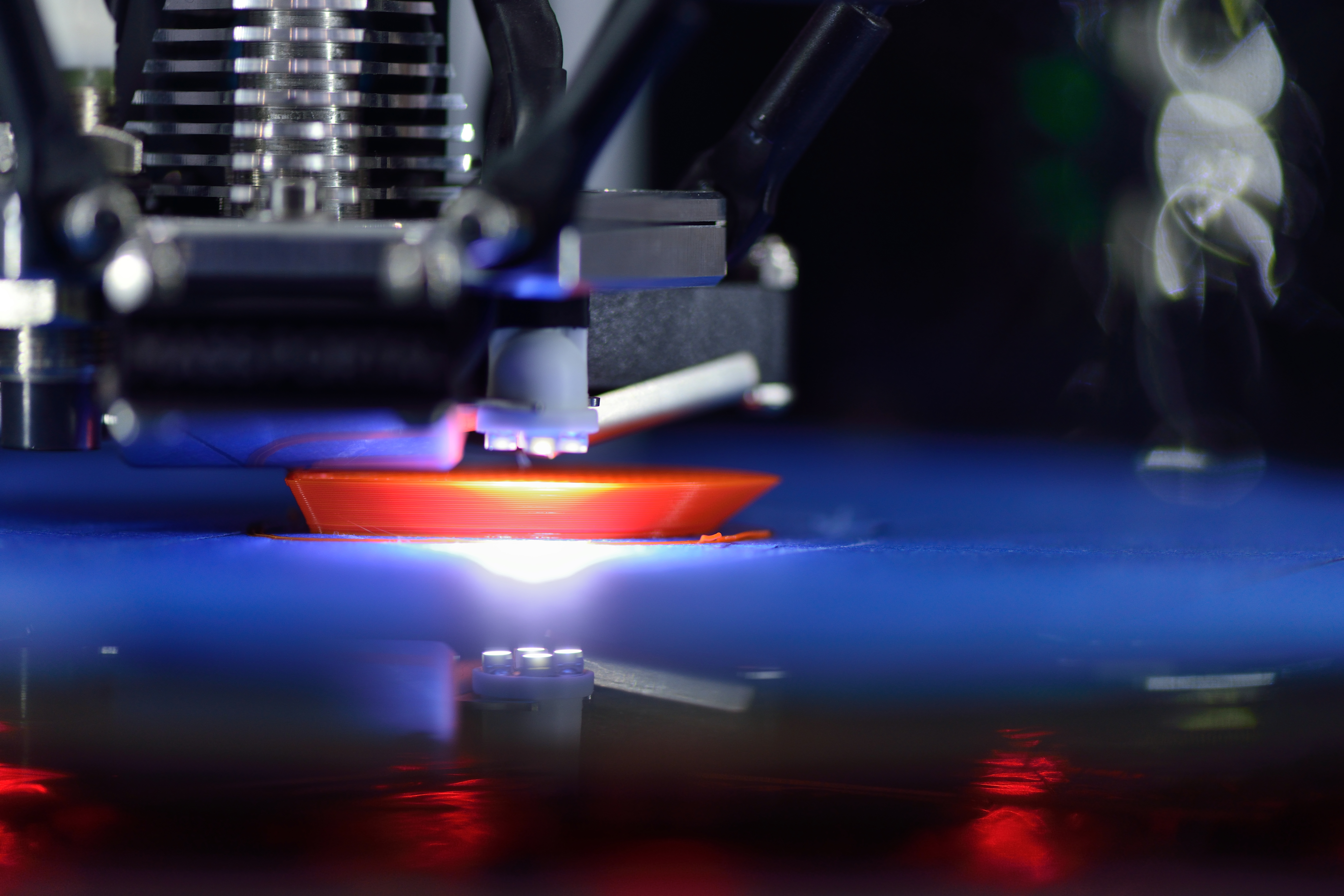

Additive manufacturing — which applies 3D printing to industrial production — reduces equipment needs, raw materials, and carbon emissions. Learn how one of our Innovation Accelerator finalists is exploring this carbon-emission-reducing avenue.

3D printing: a viable way to reduce our C02 emissions and our use of raw materials, with added customer benefits

One of our 2020 Innovation Accelerator finalists, Team Vartgass, began a proof-of-concept phase in 2021.

Taking a digitalized approach

The pilot demonstrated how additive manufacturing (AM), which applies 3D printing to industrial production, can radically reduce the size of our bioprocessing equipment. AM advances the way we approach industrial production of parts and systems, moving from analog processes to digital. Unlike traditional manufacturing, where parts are carved out or shaped, AM allows material to be added where needed, so it’s much easier to reduce materials.

Klas Marteleur, principal mechanical engineer at Cytiva, and a member of the Vartgass team, says, “The breadth of ideas shows our creativity in addressing environmental challenges. We are fortunate to get support from highly skilled mentors throughout the entire innovation journey from prototype to, hopefully, commercial success.”

Half the size, double the savings

After an eight-week bootcamp to refine the concept and explore their business case, the Vartgass team’s pilot phase was launched in 2021. It pointed to remarkable results, showing that we can shrink the size of some equipment by up to 62% compared to traditionally manufactured counterparts. This translates to less material use, such as 44% less steel in production and a 70% reduction in CO2 emissions during the customer use phase. The resulting products are also considerably lighter, which translates to fewer transport emissions.

There are benefits for our customers too. Since machines can be smaller, space is freed up in cleanrooms, allowing manufacturers to add more equipment and potentially increase their production volume.

The next phase in the project will see AM-made equipment used on the ground by customers, in addition to further iterations developed with customer feedback.

Projects like this, where the results are truly transformative, illustrate the multi-dimensional value of continuous investment in sustainable innovation.

About Cytiva

At Cytiva, we believe the key to transforming human health is accessing life-changing therapies. That’s why our 10 000+ associates in more than 40 countries are keenly focused on helping researchers, biopharma companies, and drug manufacturers to advance and accelerate therapeutics for people that need them.

Learn more about sustainability at cytiva.com/sustainability.