Meet the Anopore true pore membrane, made with proprietary electrochemical technology to provide a highly consistent pore structure useful in several areas of science. This article highlights some of the major applications of Anopore membranes and explores how they can increase the purity or yield of your analyte and simplify your analytical or manufacturing processes.

Tortuous path vs. true pore membrane filters basics

Membrane filters separate particles from fluids. Depending on the pore size, these filters can isolate particles between 10 nm and 10 µm, a range that includes yeast, bacteria, and even viruses. You might therefore use them for either particle filtration from your sample or to facilitate their analysis by removing other contaminants.

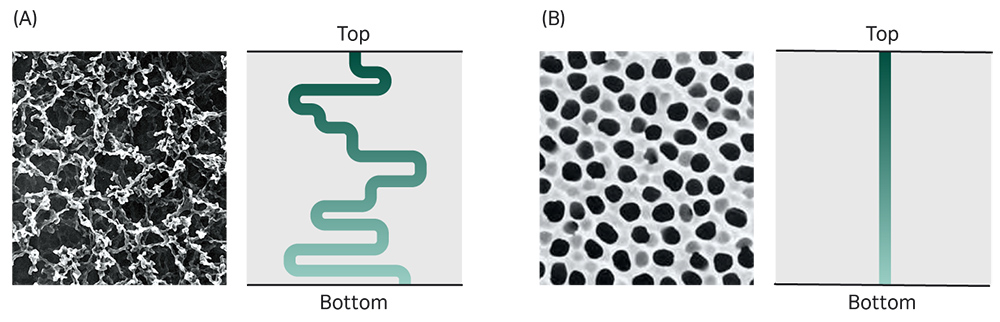

Membrane filters can be separated into two main types based on pore structure. The ‘tortuous path’ pore membranes have pores with a random, interconnected sponge-like structure (Fig 1A). Examples of tortuous path membranes include polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), and cellulose membranes.

By comparison, ‘true’ pore membranes have pores with a direct path from top to bottom of the membrane and a specific diameter (Fig 1B). Examples of this type include track-etched organic membranes, such as Whatman Nuclepore and Cyclopore membranes as well as those formed of aluminum oxide, such as Anopore membranes.

Fig 1. Comparison of tortuous path and true pore structures. (A) Image of tortuous path pores with diagram of example path through membrane. (B) Image of true path pores with diagram of example linear path through membrane.

Explore our range of Anopore membranesApplications of Anopore membranes

The proprietary process used to manufacture Anopore membranes creates pores of high density and narrow size distribution, so they can filter particles of an extremely precise size range from a sample. This manufacturing process also uses minimal additives, so Anopore membranes are chemically unreactive, giving you more confidence that particles are being filtered by size alone.

Applications for Anopore membranes are found in areas including bioprocessing, water quality monitoring, and semiconductor research. However, these membranes are used most frequently in biological research for techniques such as:

- Mobile phase filtration and degassing for high-performance liquid chromatography (HPLC)

- Filtration of bacterial cultures for microscopy

- Liposome extrusion

Applications of Anopore membranes in chromatography

HPLC mobile phase filtration and degassing

Filtration is a common and important step in HPLC sample prep. Minimizing the number of unwanted particulates in your sample protects both the pump and the column, extending the useful life of your equipment.

Upstream filtration of HPLC mobile phase also protects the pump from dissolved gas bubbles that form when mixing solvents. Damage to the pump can cause variation in the pressure and flow rate of mobile phase through the column, adding noise or variation to your experimental data. Using Anopore membranes to filter the solvent upstream of the pump can prevent premature clogging and help you to maintain consistency between experiments.

Since Anopore membranes are also low protein-binding, there is no loss of analyte during protein purification procedures.

Sample filtration for ion chromatography

Filtering out contaminating particles from samples is also an important step in sample prep for ion chromatography (IC). As IC relies on interaction between specific ions in the mobile and stationary phases to separate analytes, it is essential that any filters used in preparation minimize any leaching of ions into the sample so as not to influence results.

For this application, the Anopore filter range contains specialized Anotop IC syringe filters, which are validated to leach only 10 to 30 parts per billion of major anions, including fluoride, chloride, bromide, sulfate, nitrite, and nitrate.

Find out more about filtration and HPLC column protectionUsing Anopore membranes in microscopy

Filtering bacteria for light and fluorescence microscopy

Isolating cultured bacteria from suspension is a necessary step for various downstream analyses, including microscopy. The defined pore sizes of 0.02, 0.1, or 0.2 µm provided by Anopore membranes enable micrometer filtration of bacteria (average size 0.5-5 µm) from a sample. The membranes are also autoclavable, so you can reuse them after an experiment.

The chemical structure of Anopore membranes makes them hydrophobic and virtually transparent when wet, making the matrix almost invisible under a light microscope and eliminating the need to transfer the bacteria before microscopy. Acquiring microscopic images of bacteria on the same membrane used to filter them from culture can greatly increase the quality of your images, by avoiding the debris that is associated with transfer between different membrane types.

Anopore membranes also display low autofluorescence, so they are well-suited for fluorescence microscopy experiments. The flat, rigid structure allows you to capture more bacteria in focus than with other membrane types.

Anopore membranes in scanning electron microscopy (SEM)

Scanning electron microscopy (SEM) is a useful tool to determine the size and morphology of microorganisms. Unlike organic filters, the aluminum oxide matrix of Anopore membranes is conductive. This prevents substrate charging, enabling you to acquire high quality SEM images.

With minor modifications, Anopore membranes can also be converted into culture surfaces, enabling both culture and imaging of bacteria on a single surface.

Using Anopore membranes for particle removal and quantification

Sterilization of cell culture media

Sterilizing your cell culture media is an important step in experiments that require drug dilutions and treatments, or when preparing electrophysiology solutions. Sterile Anopore syringe filters offer a convenient method of sterilizing media.

In addition to filtering all bacteria, the sub-micrometer pore size (lowest diameter 0.02 µm) removes mycoplasma and certain viruses from solutions, giving you confidence that contaminating organisms have not influenced your in vitro experimental results.

Explore our range of Anotop syringe filtersGravimetric analysis

Gravimetric analysis is a useful technique to determine the purity of your solutions, and gives a quantitative measure of the amount of a particulate contaminant or precipitated component. This technique is often integrated into modern bioreactors used for industrial-scale cell processing.

The precise pore size offered by Anopore membranes facilitates accurate filtration of particles from solutions based on size, while the high temperature stability of these membranes (up to 400°C for Anodisc 47 mm) ensures that calculations of the weight of filtered particles after membrane drying are accurate.

Liposome extrusion with Anopore membranes

Liposome extrusion is a nanosizing procedure that yields liposomes with a highly uniform dimension. Unlike other nanosizing techniques, such as ultrasonication and freeze-thaw sonication, liposome extrusion with Anopore membranes is a simple process, involving just passing your liposome suspension through the membrane with a pump and collecting the homogenous liposomes from the filtrate.

The high density and narrow size range of Anopore membrane pores makes them well-suited for nanosizing liposome-encapsulated molecules. Pharmaceutical companies have taken advantage of this Anopore membrane capability in chemotherapeutic manufacturing using a liposome extrusion process.

Explore our range of Anopore membranesAnopore membranes are multi-functional, with a wide range of uses that extend beyond simple filtration owed to their innovative and precise pore characteristics. To find out more about Anopore membranes and filtration in general, read our lab filtration knowledge articles. Or, for support with your filtration workflows, or any of the applications mentioned, contact the Scientific Support team.