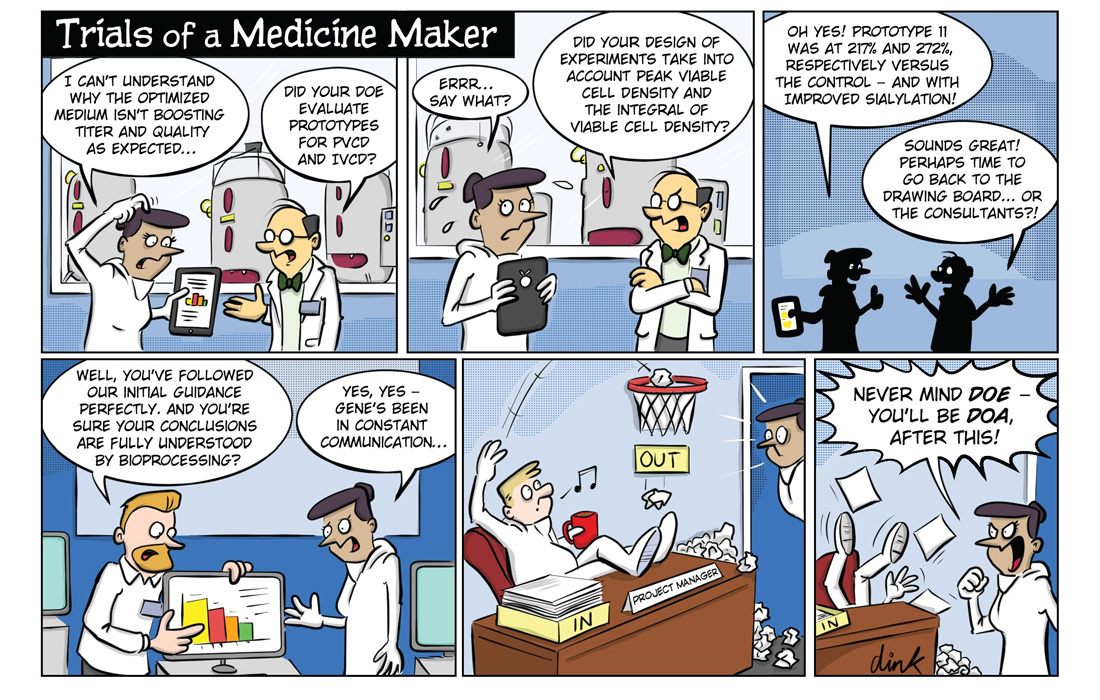

Design of experiment (DoE) in process development can help you save time and money in the long term. Not sure Gene has quite gotten the hang of this. Let’s see how Eva uses DoE to improve cell culture titer in an efficient way instead.

A little more help from Gene would go a long way. Eva seems to know the basics of design of experiments. But Gene’s project management skills are certainly in question, especially as it’s Eva who is taking the heat.

The requirements for speed and economy in the biopharma industry means increasing pressure to quickly create processes that are cost-effective and scalable. Using a DoE approach can help tackle that.

Good planning and relevant experiments make data evaluation more rigid. That way the outcome is not only generated by chance. Instead you get more robust processes and predictable outcomes. For example, the possible gains in cell culture titer and protein quality from using DoE can make a real positive impact on overall process economy.

If you want to learn DoE better, why not register to a design of experiments introduction course?