How do you use filtration in HPLC? Why might you not use filtration in HPLC sample prep and in-system, and when is it essential? And how can syringeless filters simplify your workflow, saving resources and time? Let’s find out.

Filtration and HPLC

High-Performance Liquid Chromatography (HPLC) can be both high pressure in workflow and results. Accurate analyses depend on various steps and processes working just so. An analytical lab might deal with hundreds of samples per week, each requiring fast analysis generating reliable results. This means the analyst needs to find and maintain the optimum balance between pace and quality.

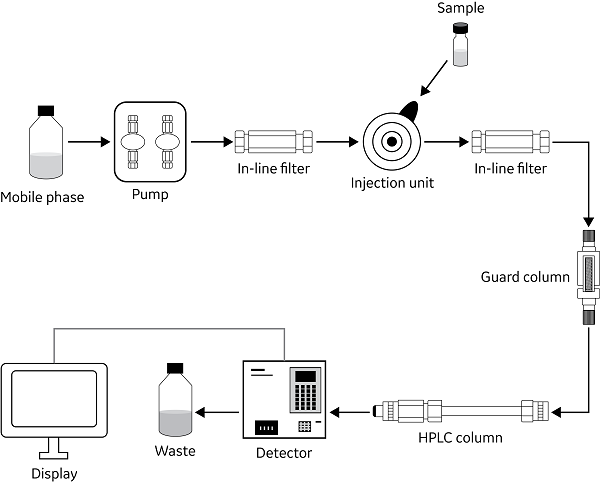

Filtration can play a key role (or not) in the HPLC workflow (Fig 1). It can be essential to delivering a clean mobile phase to the column, or it can create its own challenges. Either way, there’s no getting away from it. Not quite, anyway.

Find out more about the challenges of running an HPLC system saving time in HPLC prep

Fig 1: A typical HPLC workflow contains several opportunities for filtration.

To filter or not to filter in HPLC?

According to a recent survey by LCGC, over 70% of respondents used filtration in their HPLC workflow, making it one of the three most common components of the HPLC sample preparation workflow, along with diluting and weighing (1).

Two key reasons for using filtration during HPLC sample preparation are to:

- Protect the pump from particulates in the solvent or released from rubber components.

- Prevent particulates clogging and damage the delicate HPLC column.

Protecting the pump

The pump is one of the components susceptible to premature failure, leading to leaky or no flow from the pump. Particulates can accelerate wear on valves, pistons, and seals, and show up as noisy or irregular baselines in analysis, or as variations in pressure and flow rate.

These issues can affect the sharpness of peaks, complicating analysis of results, and certainly calling into question the accuracy and reliability of those results.

A simple solution to this challenge is filtration upstream of the pump, preferably to at least 0.45 µm. You could do this off-line or continuously in-line, but it potentially adds cost and time to the workflow. Alternatively, you could purchase premixed and filtered solvents, which also minimizes the potential for contamination of the solvent.

If you’re introducing solid additives, you’ll most likely need to filter anyway, even if you use premixed solvents. So, ultimately, the decision to filter or not to filter upstream of the pump depends on your context.

You might want to weigh up the cost of filtration (including purchasing premixed solvents) versus the cost of pump maintenance and downtime. In laboratories dealing with a continuous stream of HPLC samples, the cost of the pump being out of action could be a lot higher than in a lab where there is only an occasional HPLC sample to analyze.

Labs carrying out 24/7, high-throughput HPLC analysis could likely justify the extra cost of implementing filtration, both in terms of minimizing downtime and maximizing the quality of results.

Protecting the column

HPLC column frits reduce the risk of unwanted particulates entering the column, but these frits can also get clogged, making the column unusable and increasing the frequency of HPLC column maintenance. Even if the solvent from the pump is particle-free, valves downstream of the pump can degrade and the sample itself can contain and introduce particulates.

Filtration, again, is a potential solution.

In-line filters can reduce the risk of particulates reaching the column. That’s their sole purpose, and high-performance filters are designed to withstand the pressures in an HPLC system, despite having very small pore sizes. They can considerably lengthen the lifetime of the column.

Guard columns can perform a similar function but are considerably more expensive to replace than a few in-line filters, often 10-20% of the column purchase price each. It would be more cost effective to just use them for chemical protection of the analytical column.

Lastly, we come to the sample itself. The potential variety of sample types and sources creates an equally possible variety of particulates that could enter the HPLC system. In-line filters might catch these particulates, but perhaps not before they cause wear to valves and seals in the injection unit, creating more particulates.

A filtration step before injecting the sample or, indeed, at the point of collection, could effectively eliminate these particulates.

Choose Whatman GD/X filters for hard-to-filter samples prior to HPLC

The most appropriate level of filtration for HPLC

All this sounds like a lot of filtration, and that is potentially a reason not to use it, or at least not so much of it!

Introducing filtration into a workflow creates additional steps where errors could occur. However, there are ways to mitigate these risks, such as implementing a strict SOP and selecting a filter tailored to the application.

Using the same type of filter for every sample creates a risk of extractables contaminating the sample. Similarly, if the filtration apparatus isn’t as clean as it could be, there’s a risk of particulates and chemical contaminants carrying over to the next sample.

In sensitive applications with small peak volumes, each additional filter might also contribute to peak broadening, and so make analysis that much more difficult.

Cost is also a factor. That is, the cost of filtering versus the costs resulting from pump problems, premature column degradation, and the risk of needing to repeat analyses.

So, there’s a balance to achieve. Enough filtration that you screen out damaging particulates, but not so much that you spend an untoward amount of time and resources replacing filters. High-quality filter devices of the appropriate type for the step and sample can protect your HPLC equipment while minimizing cost.

Using syringeless filters for HPLC sample prep

Preparing HPLC samples using traditional syringe filters often results in the loss of some sample in the syringe. This can make it difficult to get a reading and so you might just decide to save the trouble and not to use the filter at all.

This is one of the reasons why we developed the Whatman Mini-UniPrep and glass-based Mini-UniPrep G2 syringeless filters.

Syringeless filters can remove particulates whilst leaving the sample intact. This promises greater consistency in results and longevity of the HPLC system and measuring instruments.

The Mini-UniPrep filter devices are designed in a way that removes the need for a syringe and results in a filter that can prepare samples for HPLC and ultra-HPLC (UHPLC) three times faster than conventional sample filtration methods.

Not only are the Whatman Mini-UniPrep filters kinder on your workflow, but they’re also kinder on the environment. By combining several products into one, they require 80% less material than conventional methods (Fig 2).

Fig 2: Replace four separate products with one with Whatman Mini-UniPrep syringeless filters. Kinder to your workflow and to the environment.

However, if you do need to use syringe filters in your HPLC workflow, making sure they are designed for HPLC and appropriate to your specific samples can make a world of difference to the final quality of results.

For example, Whatman SPARTAN syringe filters have excellent chemical resistance to common aqueous and organic solvents. They are suitable for both UHPLC and HPLC, designed to remove large particles that can damage HPLC columns, and have documented batch-to-batch reproducibility and quality. All of these factors combine to make sure you can generate accurate and reproducible results.

Whatman SPARTAN syringe filters make HPLC sample preparation easier and more reliable

Also, the Whatman Puradisc GD/X syringe filter range can be tailored to your specific application. The filters are perfect for hard-filter samples, are available in sterile and non-sterile options and come with eight 16 material and three two size options to suit different solvents and volumes in addition to a range of pore sizes.

Whatman GD/X syringe filters combine premium quality with a range of effective options

Moving forward with filtration in HPLC

As the need for quality and throughput ever-increases, there is a trend towards automated HPLC sample preparation. Analysts are being asked to handle increasing numbers of samples—hundreds per week—and so automation is becoming an essential part of the HPLC workflow.

Supporting automated sample preparation

As an increasing percentage of analysts are expecting to use automation, there’s a need to support the enhanced and higher-throughput workflows.

Autosamplers are the most popular type of automation, with full laboratory robotics less common, likely down to cost.

Whatman Mini-UniPrep filters incorporate an autosampler vial, filtration membrane, plunger, and cap in one consumable product, making them well suited for automated sample preparation. These are just one of a range of solutions for current and future HPLC sample preparation needs we’ve developed at GE Healthcare Life Sciences.

Sometimes, the decision to filter (or not), and which filter is the ‘right’ one is down to individual preference and needs. Try our Whatman Filter Selector App to find the most appropriate filtration solutions for your samples. Or, read our other blogs and articles for more information and advice on filtration.

If you’d like to discuss options for improving your HPLC workflow, including anything related to filtration practices or automation, please contact the GE Healthcare Scientific Support team or your local representative.

References

- LCGC. Improving Sample Preparation in HPLC. (2017).