Disposable, 96-well filter plates prefilled with chromatography resins are suited for high-throughput screening of resins and chromatographic conditions such as binding, wash, and elution conditions. These 96-well plates offer an essential first step to determine the optimal conditions that will ultimately be used for large-scale purification of a range of important biotherapeutics such as monoclonal antibodies and for manufacture of vaccines.

This blog article presents an overview of the workflow using PreDictor 96-well plates, together with a checklist of equipment required for running high-throughput process development (HTPD) experiments with these tools.

HTPD and parallel chromatography

Efficient development of the manufacturing process is a crucial component of the overall biopharmaceutical development.

High-throughput process development shortens development time and at the same time increases the amount of information available during early process development.

HTPD workflow using PreDictor 96-well plates

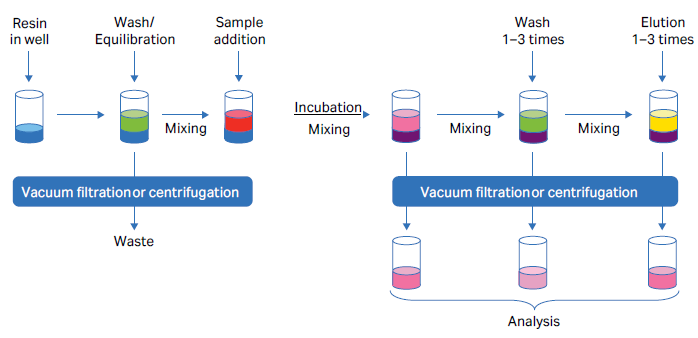

The workflow using PreDictor plates is performed in a batch mode and comprises the same steps as any chromatography column experiment: equilibration of the resin with the desired buffer, sample application, wash, and elution (Fig 1).

The workflow starts with conditioning of the resin by repeated addition of equilibration/binding buffer.

Sample in binding buffer is then added to the resin and incubation is started. All incubations, whether with buffer or sample, are performed with agitation on a shaker, while separation of phases is performed by centrifugation or vacuum filtration.

The sample solution is then removed by repeated washes with chosen solution, followed by repeated elution with the chosen conditions.

Watch a demonstration of a manual operation using PreDictor plates

Fig 1. Steps in batch purification using PreDictor 96-well plates.

Equipment checklist for using PreDictor 96-well plates

The list in Table 1 outlines the material you need to gather prior to working with PreDictor plates.

Table 1. Equipment checklist for getting started with PreDictor plates

| PreDictor plate | Select the appropriate PreDictor plate with the Purify App. A selection of our PreDictor plates can be found here. |

| Collection plates | Collection plate for 96-well plates, 28403943 |

| Microplate foil | Product code: 28975816 |

| UV-readable collection plates | Corning™ Costar™ 3635 UV plate 96 clear bottom |

| Multichannel pipette | Any 8- or 12-channel pipette |

| Buffer container (v-shaped) | To be used when you want the same condition in all wells in the plate; Eppendorf™ reagent reservoir, autoclavable reservoir for multichannel pipette, filling volume 50–60 mL, 1 set = 10 pcs (0030 058.607). |

| Buffer/storage plates with 48 or 96 wells for buffer preparation | For the different conditions studied. Seahorse™ Bioscience or Whatman UNIplate, 7701-5200 or similar. Format:

|

| Vacuum manifold | Multiwell vacuum manifold from PALL, part number: 5017 Accessories:

|

| Microplate shaker | IKA™ MTS 2/4 digital microtiter shaker Identity number: 3208000 |

| Centrifuge | Equipped with holders for 96-well plates |