FAQ

What Is the Hold Up Volume (Void Volume) of My Normal Flow Filter?

ULTA Pure SG, ULTA Pure HC and ULTA Prime CG

Data for hold-up volume is approximate and was generated using ULTA PUre SG capsules. No significant differences are expected for ULTA Pure HC, ULTA MR or ULTA Prime CG which employ similar materials of construction.

| Hold-up volume | |||

| 1 barq air purge | 2 barg air purge | 3.7 barg air purge | |

| 10-inch capsule | 184.4ml | -- | 119.6ml |

| 6-inch capsule | 61.4ml | 40.5ml | -- |

| 4-inch capsule | 31.4ml | 21.6ml | -- |

| 2-inch capsule | 19.4ml | 15.2ml | -- |

ULTAPrime GF

| Hold-up volume | ||

| 1 barq air purge | 2 barg air purge | |

| 6-inch capsule | 46.8ml | 44.4ml |

| 4-inch capsule | 27.5ml | 25.5ml |

| 2-inch capsule | 12.9ml | 11.1ml |

ULTA Prime PP

| Hold-up volume | ||

| 1 barq air purge | 2 barg air purge | |

| 6-inch capsule | 45.0ml | 39.8ml |

| 4-inch capsule | 18.0ml | 14.5ml |

| 2-inch capsule | 11.3ml | 10.1ml |

When Performing Disc Tests, Do I Need to Use an Underdrain (Support) Material?

What Is a Bioburden Reduction Filter (ULTA Prime CG)?

Bioburden reduction filters are not defined by an industry standard. The term “bioburden reduction” is a designation used to describe a class of filters which provide a high level of microorganism retention (i.e., LRV 4-6), but do not yield a sterile effluent under the high bacterial load called for in the ASTM F838-05 test method. Manufacturer claims on bioburden reduction filters vary from “typical” retention data to full validation of a minimum LRV. In practice, most bioburden reduction filters are of a 0.45 or 0.2 µm rating and may yield a sterile fluid in common usage, where bacterial loads are much lower than those used in the ASTM challenge. Nevertheless, process-specific claims of fluid sterilization through the use of a bioburden reduction filter are generally not appropriate.

Are the Pores of ULTA Pure Membranes Symmetric or Asymmetric?

Does Autoclaving Have an Effect on Membrane Capacity?

No. To demonstrate the effect of autoclaving, three ULTA Pure SG discs were autoclaved at 125ºC for 30 minutes. The capacity of these discs was measured under constant pressure conditions using 1% bovine serum albumin in phosphate-buffered saline. As a comparison, the capacity of three new ULTA Pure SG discs was also measured under the same conditions. A 4% difference of capacity was measured, which is well within the experimental error of the method.

Summary of Capacity Testing (L/m2)(N=3)

| Non-sterile (mean) | Autoclaved (mean) | Difference (%) | |

| ULTA Pure SG | 1249 | 1197 | 4% |

Can I Gamma-Irradiate my ULTA Filters?

Can I Autoclave ULTA Filters?

Can ULTA Filters Be Used in the Reverse Direction?

ULTA filters are bi-directionally supported but Cytiva has not validated their reverse flow capability. If an ULTA filter is inadvertently pressurized in reverse, an integrity test should be performed to determine if the filter has maintained its integrity.

What is "Airlocking"?

Airlocking is the situation which occurs when a large air bubble enters a capsule or housing containing a wetted sterilizing-grade membrane. Sterilizing-grade membranes will not pass air at pressures lower than their bubble point and therefore large quantities of air will prevent liquid from flowing through the membrane. This situation can be alleviated by venting the housing or capsule of entrapped air—once the air is purged liquid flow through the filter should resume.

How Do I Recover the Hold Up Volume from an ULTA Capsule or Cartridge?

The most common methodology is to follow the fluid with clean compressed air. For sterilizing grade membranes, it will be necessary to exceed the bubble point (3.38 bar) of the 0.2 membrane to completely recover the fluid in the filter’s core.

Yes. ReadyToProcess capsules are available in 2-inch, 4-inch and 6-inch sizes for the ULTA Pure SG, ULTA MR and ULTA Pure HC products. ReadyToProcess capsules are sterilized via gamma-irradiation and Cytiva maintains a sterility claim on these products.

Accessories

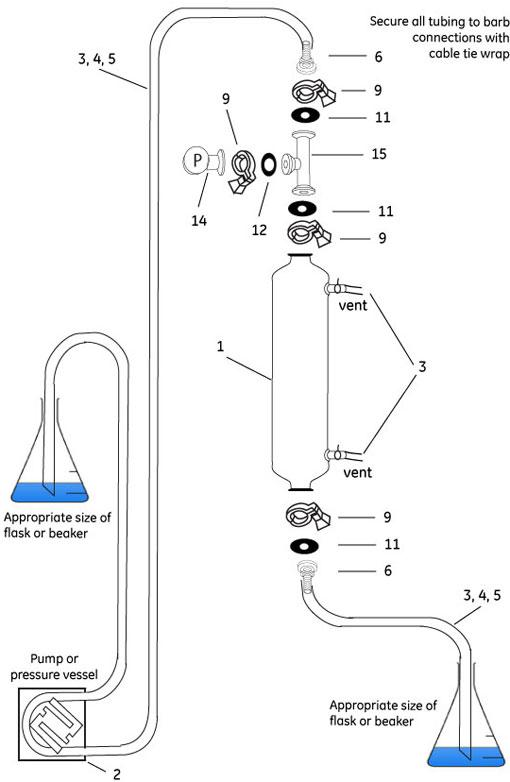

The setup in the figure below are recommendations if your required pump capacity is between 72 ml/min and 13 liters/min.

Details available below:

Peristaltic pump for flow rates up to 2 liters/min (56-4106-53)

Peristaltic pump for flow rates up to 13 liters/min (11-0005-66 and 11-0005-67)

Countries using 220 V power, have to order power cords separately for the pumps.

Please note that the item numbers are not necessarily in sequential order.

* 2 inch capsules have female Luer vent connection, a connector male Luer - hose barb and suitable tubing has to be assembled on the vent outlet. For connector male Luer - hose barb, please contact other supplier.

| # | Product Name | Product Code | Price | |

|---|---|---|---|---|

| 3 | Peristaltic Tubing, size 17, 3.1 m, i.d. 6.4 mm, bioprene | 56410618 | 153.18 USD |

Add to cart

|

| 4 | Peristaltic Tubing, size 18, 3.1 m, i.d. 9.5 mm, bioprene | 56410619 | 171.81 USD |

Add to cart

|

| 5 | Peristaltic Tubing, size 82, 7.6 m, i.d. 13 mm, bioprene | 56410622 | 590.00 USD |

Add to cart

|

| 5 | Peristaltic Tubing, size 82, 7.6 m, i.d. 13 mm, silicone | 56410623 | 628.00 USD |

Add to cart

|

| 6 | 25 mm (0.5") TC 9.5 mm (0.375") Barb | 56410980 | 132.48 USD |

Add to cart

|

| 6 | 25 mm TC 13 mm (0.5") Barb | 56410981 | 202.00 USD |

Add to cart

|

| 9 | Clamp 25 mm TC | 56410665 | 161.46 USD |

Add to cart

|

| 9 | Clamp 25 mm TC | 56410666 | 115.92 USD |

Add to cart

|

| 11 | Gasket 25 mm (0.5") TC i.d. 13 mm, silicone | 56410994 | 78.66 USD |

Add to cart

|

| 12 | Gasket 25 mm (0.75") TC i.d. 19 mm, silicone | 56410995 | 78.66 USD |

Add to cart

|

| 14 | Pressure Gauge 0-2 barg (0-30 psig) 25 mm (0.75") TC, side mount | 56410600 | 1,398.00 USD |

Add to cart

|

Troubleshooting

Find solutions to product related issues. For unlisted issues please contact local Cytiva service representation.

Normal Flow Filtration

Please check the following during troubleshooting:

Lower than expected flow rate or capacity

If not done previously, small scale (25- or 47-mm) testing should be performed to confirm the filter selection. Filter capacities less than 150 L/m2 generally indicate that prefiltration is required..

If previous tests have been performed and scale-up calculations have been made on a liters per square meter basis, premature plugging may indicate that fluid characteristics have changed since the initial filter sizing trials were conducted.

Ensure that the filter housing is properly vented before use. Air-locking will lead to lower than expected flow rates. This can be done via the filter vent which is present on each device.

For high viscosity streams or fluids containing a high solute concentration, prewetting the filter with purified water or formulation buffer may improve process flow rates.

Failed integrity tests

Note: Sterilizing grade and bioburden reducing membrane filters should be tested for integrity. This can be done before use, after steam-in-place and/or after use. Integrity testing assures that the filters are integral and that the proper pore size filter is installed.

Check that the filter has been properly wet with purified water and that no residual process fluids are left on the membrane. If necessary, reflush the filter following the cartridge operating instructions.

For cartridge filters, check to ensure that the filter cartridges are properly installed. Double O-ring cartridge adapters should be fully seated and locking tabs, if so equipped, should be engaged to prevent filters from being dislodged due to back pressure. If the cartridge appears to be installed correctly, inspect the O-rings for damage.

Check that the temperature of the filter is held constant during the integrity test procedure. Filters should be flushed with water that is at a temperature close to the temperature of the integrity test gas. Filter and filter housing cooling is a common cause of false integrity failures.

Check that no system leaks are present. This can be verified by removing the filter from the housing and performing a pressure-hold test on the housing and associated piping.

Steam-in-place issues

Cartridge deformation: Cartridge deformation includes collapse of the filter core and warping of the code-7 tabs. This is generally caused by exposure to high differential pressure at SIP temperatures.

Cartridge melting: This is an indication of excessive steam temperature and pressure.

Cartridge discoloration: Generally caused by contaminants present in the steam. Steam generators and delivery systems should be cleaned and/or sanitized. If the problem persists, a steam filter should be added to the delivery system.

Autoclave issues

Capsule deformation: Capsule deformation is generally caused by flow restrictions on the capsule inlet and outlet. Sources of flow restriction include: impermeable caps placed on the inlet & outlet fittings, crimped tubing and tubing which joins the filter inlet and outlet ports.

Fitting distortion: Especially common for sanitary (tri-clamp) connections, fitting distortion is caused:

- When capsules support excessive weight during the elevated temperature of autoclave cycles. Proper fixtures should be designed to support the weight of external fittings during autoclaving.

- By sanitary clamps which are over-tightened prior to autoclaving. Three part clamps are preferable to two part clamps because they distribute clamping forces in a more uniform fashion. Nylon clamps are preferable to stainless steel because they expand and contract in a fashion more like the capsule materials. Additionally, nylon clamps generally include a stop which prevents over tightening.