Powder-liquid mixing is a common requirement in biopharmaceutical processing for media and buffer preparation. This can pose a challenge to ensure complete mixing is achieved in an acceptable time. This can be at risk if a mixer used provides insufficient power input, resulting in an inability to create a vortex. For this reason, we evaluated the mixing performance of the 3000 L Xcellerex™ magnetic mixer system for preparation of aqueous solutions.

Introduction

We evaluated the mixing performance of the 3000 L Xcellerex™ magnetic mixer system for preparation of a typical floating powder (Dulbecco's Modified Eagle Medium [DMEM]) and a typical sinking powder (sodium chloride) (Fig 1). The required time to achieve homogeneity was assessed both visually by the time at which no undissolved solids remained visible, and by using a conductivity sensor. The solution was homogenous at the time when the conductivity sensor had stabilized within ±1%.

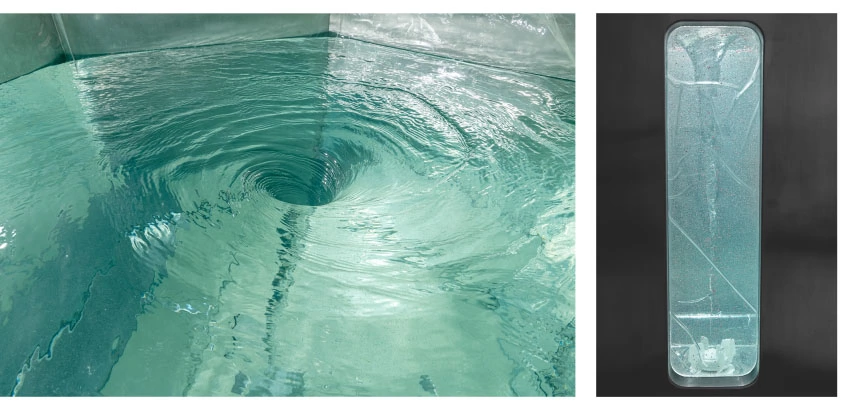

Fig 1. 3000 L Xcellerex™ magnetic mixer system.

Fig 2. Top view and front view of Xcellerex™ magnetic mixer showing vortex capabilities at 3000 L processing volume.

Materials and methods

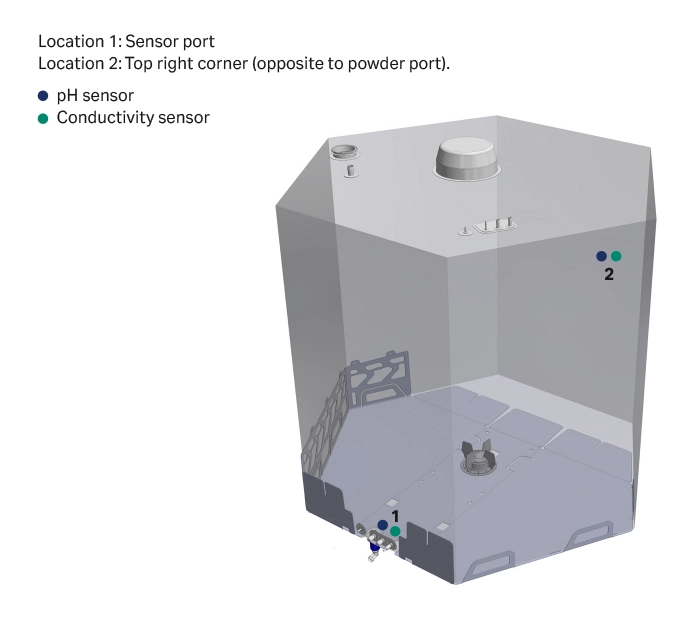

The materials and equipment used in this experiment are presented in Table 1. The 3000 L Xcellerex™ magnetic mixer was prepared according to its instructions for use. The single-use mixing system was installed and inflated, and the pre-calibrated pH and conductivity sensors were installed at the locations as shown in Figure 3. The single-use system then was filled with demineralized water to 90% of the nominal mixer volume. Mixing was started at an impeller speed of 310 rotations per minute (rpm), data recording was initiated, and then the required quantity of powder was added. In the case of DMEM, an additional pH adjustment step was required with a sodium bicarbonate addition once the media solution was clear of solid particles, and when conductivity values had stabilized for five minutes (min). The media preparation was finally completed with a demineralized water addition to reach 100% of the nominal volume.

Table 1. Materials and equipment

| Equipment | Supplier | Product number |

| Xcellerex™ magnetic mixer 3000 L system including thermal jacket and load cells | Cytiva | XM3000JHT-B4N |

| pH sensors | Mettler-Toledo | InPro325i/SG/120 |

| Conductivity sensors | Mettler-Toledo | InPro7100/12/120/4435 |

| M300 2-channel transmitter | Mettler-Toledo | ING30280773 |

| Xcellerex™ magnetic mixer 3000 L single-use system | Cytiva | 6407-1067Z |

| 3000 L inflation set | Cytiva | 6407-1243S |

| Demineralized water | IMES | IMS3774742 |

| Single and double-concentrated DMEM (13.4 g/L and 26.8 g/L, respectively) | Sigma Aldrich | D5648 |

| 1.5 M Sodium chloride (NaCl 98%) | Marsel | 21018 |

| 3.7 g/L and 7.4 g/L, pH adjusted sodium bicarbonate (NaHCO3) | Sigma Aldrich | S5761-5KG |

Fig 3. Schematic drawing of the 3000 L Xcellerex™ magnetic mixer single-use system with the pH and conductivity sensor locations.

The test conditions are presented in Table 2.

Table 2. Test conditions

| Parameter | Test condition |

| Working volume | 3000 L |

| Temperature | Room (20 ± 2°C) |

| Mixing parameters | pH, conductivity, visual |

| Agitation speed | 310 rpm |

| Mixing time criteria | Visual and conductivity ± 1% |

Results and discussions

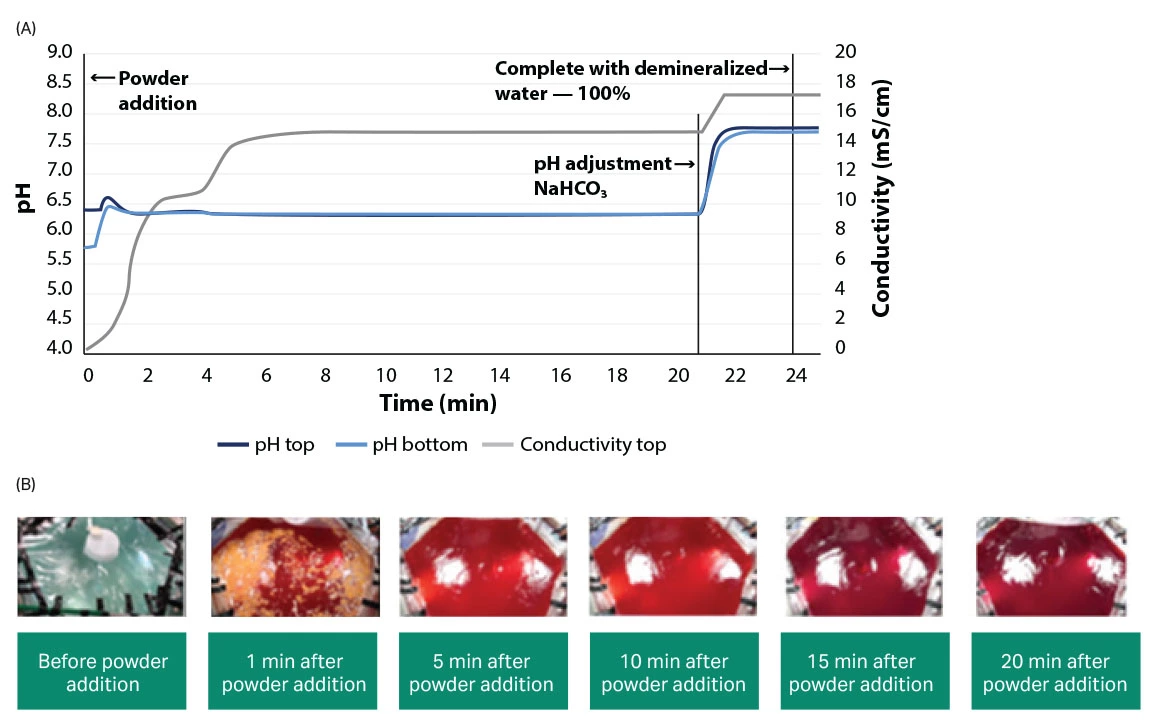

For the 1× DMEM mixing experiment, the 3000 L Xcellerex™ magnetic mixer was filled with 2700 L of demineralized water and mixing started at 310 rpm. Once stable, 40.2 kg of 1× DMEM was added via the powder port within 4 min 20 seconds (s). Conductivity was stable after 5 min and 45 s and media was clear of undissolved particles after 6 min 40 s of mixing. Sodium bicarbonate was added at 20 min to adjust the pH of the media to 7.5. Once final pH was reached, demineralized water was added up to 100% of the nominal volume to complete media preparation.

Fig 4. (A) Graph of pH and conductivity, and (B) photos of 1x DMEM mixing in 3000 L Xcellerex magnetic mixer.

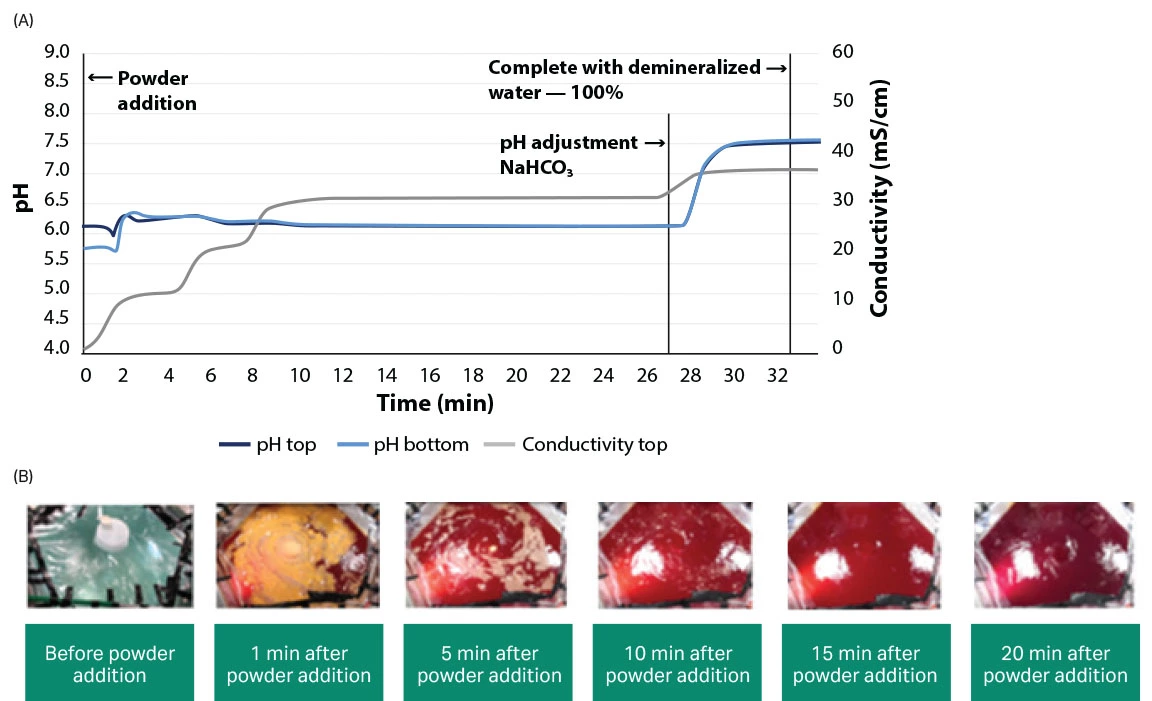

For the 2× DMEM mixing experiment, the 3000 L Xcellerex™ magnetic mixer was filled with 2700 L of demineralized water and mixing started at the speed of 310 rpm. Once stable, 80.4 kg of DMEM was added via the powder port in 8 min 26 s. Conductivity was stable after 10 min 7 s, and media was clear of undissolved particles after 8 min 8 s of mixing. Sodium bicarbonate was added at 27 min to adjust the pH to 7.5. Once the final pH was reached, demineralized water was added up to 100% of the nominal volume to complete media preparation.

Fig 5. (A) Graph of pH and conductivity, and (B) photos of 2× DMEM mixing in 3000 L Xcellerex™ magnetic mixer

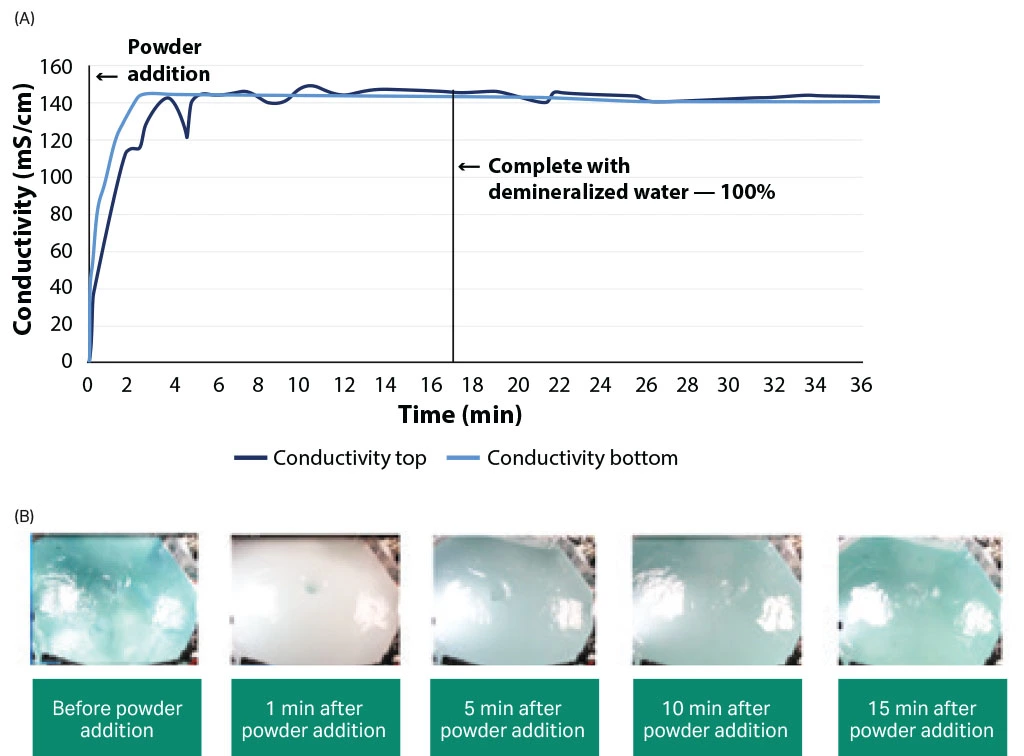

For the 1.5 M NaCl mixing experiment, the 3000 L Xcellerex™ magnetic mixer was filled with 2700 L of demineralized water and mixing started at the speed of 310 rpm. Once stable, 262.98 kg of sodium chloride was added via the powder port in 2 min 45 s. Final conductivity was reached after 4 min and 49 s of mixing, and the solution was clear of undissolved particles within 5 minutes. Once final conductivity was reached and remained stable for five minutes, demineralized water was added up to 100% of the nominal volume.

Fig 6. NaCl 1.5 M mixing in the 3000 L Xcellerex™ magnetic mixer.

A summary of the mixing times for the various experiments are presented in Table 3.

Table 3. Visual and conductivity based mixing times, presented as mixing time excluding the powder addition time (Mixing time including the powder addition time)

| Media and buffer concentrations | Visual (min:s) | Conductivity (min:s) |

| 1× DMEM | Excluding powder addition time 6:40 Including powder addition time (10:00) |

Excluding powder addition time 6:40 Including powder addition time (10:00) |

| 2× DMEM | Excluding powder addition time 8:08 Including powder addition time (16:34) |

Excluding powder addition time 10:07 Including powder addition time (18:31) |

| 1.5 M NaCl | Excluding powder addition time 5:00 Including powder addition time (7:45) |

Excluding powder addition time 4:49 Including powder addition time (7:34) |

Conclusions

The results of this study confirm the ability of the 3000 L Xcellerex™ magnetic mixer to disperse and dissolve the selected floating powder (DMEM, both single and double concentration) and sinking powder (1.5 M sodium chloride) within a timeframe of 20 min, including powder addition time.