Introduction

Cell therapies, viral vectors, plasmids, mAbs — advanced therapies are the future of how we will treat cancer, immune, neurologic and genetic conditions, and devastating rare diseases — but delivering them at scale is challenging. What are the specific obstacles to expanding manufacturing capacity? What does one need to consider for a successful “CapEx” project?

We invited several cell therapy industry leaders to participate in a panel discussion to share their thoughts and first-hand experiences. It's clear from the conversation that scalable, flexible, proven solutions will solve most issues, from time constraints and bandwidth issues to scientific expertise and staffing shortages. Continue reading to learn what to look for in a solutions provider and what these leaders recommend for navigating your road ahead.

Speakers

Iovance Biotherapeutics, Inc.

Executive Director, Process Development

Charles River Laboratories

Executive Director, Scientific Services Cell and Gene Therapy

Germfree

VP of Quality & Business Strategy

ElevateBio, BaseCamp

COO

Genocea

Executive Vice President, Pharmaceutical Sciences and Manufacturing

Cytiva

Cell and Gene Therapy Enterprise Technical Leader

Consideration 1: scalability

Do you have processes in place that are scalable?

Speed: it’s both a pressure point and a key metric of success for those looking to expand their cell therapy manufacturing capacity. And with 30.7% of biotherapeutic developers and contract manufacturing organizations ranking “will scale-up” as one of their top plans for GMP and commercial manufacturing (1), the speed at which you expand your capacity can be crucial.

What’s important for speedy commercial manufacturing? “Technology readiness. Process readiness. Facility readiness,” notes Erwin Cammaart, executive director in process development at Iovance Biotherapeutics, a late-stage oncology company dedicated to fighting solid tumors. When globalizing or expanding facilities, these timelines often come together — at the same time. “And that is a huge challenge,” Erwin says. “Often, it is the technology development that may be on the rate-limiting step.”

So, if you can only proceed as fast as your slowest step, how do you standardize some of that scalability?

“You have to create what I've always called that line of sight,” advises Ray Stapleton, executive vice president and chief technology officer for Genocea Sciences, a Cambridge-based bioscience company developing personalized cancer vaccines and immunotherapies. “That [line of sight] operates as your true north.”

In an industry that seems to move a mile a minute, it can feel like there’s pressure to expand your facilities at the same rate. However, gaps in your current processes have a high likelihood to grow as you expand. With cell-based therapies, the product is the process. So, how does process development feed into your expansion plans?

“Your regulatory strategy is critical,” according to Stapleton. “Take advantage of the stage you're in, early on. Later on, it's much more difficult to change.” It’s important to be efficient and purposeful with process development. “We can't afford to wander through intellectual curiosity,” Ray continued. “It has to be on that true north that we have as the line of sight to get to the market.”

But when implementing automation, how soon should you factor in all-in-one solutions that may not be flexible enough to adapt to your business needs? You must consider solutions that can grow with you, as your business grows. Your solutions should be able to handle both autologous and allogeneic therapy developments, for example.Ultimately, it’s crucial to consider flexible solutions early on, in addition to weighing in cost reductions and new technologies.

Cammaart notes the importance of not only addressing these concepts early on, but also revisiting these questions often. “Do we still have all the drivers in place? Are there still cost reductions? Are we still talking about reduction of manual touchpoints? Is it actually labor-reduced? Every milestone you have to revisit [these questions]. And make sure you're still on track.”

Stapleton adds, “As you scale, it's not just [a question of] are you scaling the process — it's everything around the process. It's all of your suppliers...Make sure that [anything in your process that is unique to you], whatever it is, is ready to go and ready to scale when you scale.”

Consideration two: flexibility

Does your solutions provider enable you with flexibility to overcome challenges unique to your business?

Bandwidth concerns continue to be a pressure point for those who are adding manufacturing capacity. Our panelists noted that oftentimes, you simply can’t do it all.

“Make sure you understand what your internal capabilities are and be honest with yourself,” Stapleton says. “Whether it's infrastructure for a PD lab or analytical lab. Whether it's your HR capabilities. Be honest. If you're a small group…it's fairly unlikely you're going to have a deep bench in a lot of these spaces.”

Carol Houts, executive for regulatory and clinical development at advanced cleanroom manufacturer, Germfree, agrees. “Unfortunately, many companies are strapped when the next round of financing is happening…you don’t always get a chance to really look at the overall vision.” How do you ultimately maximize the capital spend? Houts continues, “A lot of times, companies are making that choice. Do I take on a CapEx project where I’m going to put money into facility infrastructure? Or can I use OpEx money to be able to then enroll more patients? So, these are difficult choices that companies are making every day when it comes to trying to decide to invest in capacity.”

Think about what you might outsource, the panelists suggest. “Smaller companies can't do everything,” notes Mike Paglia, chief operating officer at ElevateBio Basecamp, a dedicated cell and gene therapy process innovation center in Waltham, Massachusetts. “We try to encourage [smaller companies] that there are ways to work with us to be able to accelerate [while still owning their own processes].”

The cell therapy space is growing. And as it grows, so too does one large piece of the bandwidth challenge: shortage of talent.

Matthew Hewitt, the executive director for scientific solutions for cell and gene therapies at Charles River Laboratories, a contract research organization, agrees. “I think it’s laudable that everybody wants to maintain their independence given the imbalance between supply and demand for…plasmid, to vector, and cell therapy manufacturing facilities. But if we all start building our own facilities, we’re going to make a talent problem much worse.”

In fact, within the next two years, 62% of employers intend to recruit to expand their workforces, with most companies looking for skilled and experienced people (2). Plus, in 2021, biotherapeutic developers and contract manufacturing organizations ranked hiring more staff with cell/gene therapy expertise as the second most-needed improvement in the cell and gene therapy manufacturing space (3). One question we posed to the panelists: How much does the staffing shortage factor into choosing the areas in which to move forward with capacity expansion?

“We're trying to increase patient access to these therapies through cost reductions. So, we also need to keep in mind that given the talent crunch, we need to increase the accessibility for people to actually be able to do these processes for us in a GMP environment,” says Hewitt. Once you’ve successfully moved to a closed and automated system, the gowning requirements change, which lowers the employment barriers to entry. “That will help a lot with the talent crunch we're seeing,” Hewitt adds, “because we need a lot more people executing manufacturing.”

But adding manufacturing capacity isn’t one size fits all. The direct effects of bandwidth and labor shortage issues vary among small, medium, and large companies. That’s why flexibility is key. Being able to fill the gaps with flexible solutions that keep pace with your growing capacity needs is essential.

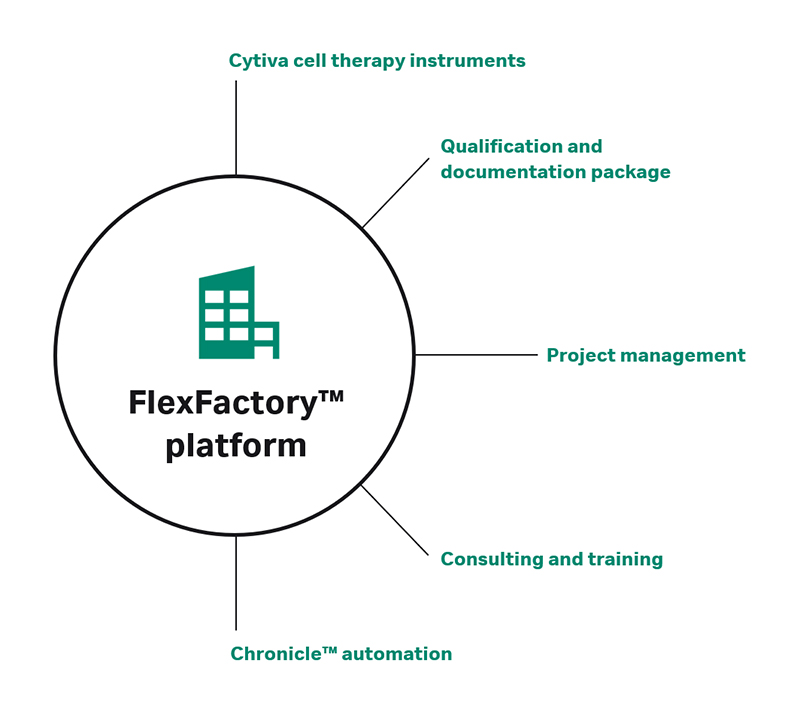

ElevateBio experienced this firsthand. Their need? To meet the goals of a diverse client and product portfolio through adaptable solutions. And the FlexFactory™ platform got them there. Through that flexible platform, ElevateBio was able to rapidly build lentivirus and AAV platforms in the PD laboratory, in addition to scaling to GMP in the cleanroom.

The concept of optionality — the ability to retain options or flexibility versus an “all or nothing” concept — is essential when adding manufacturing capacity. Optionality goes hand-in-hand with expansion, because it allows you to keep your options open while you navigate uncertain paths. In fact, it’s of benefit to look for a solutions provider that offers many different types of manufacturing solutions: from different types of cell therapy, viral vectors, plasmids, mRNA, oligonucleotides, and antibody-derived molecules. This flexibility offers the possibility to pivot to different molecule types as your program evolves.

So, at the beginning of the capacity expansion process, consider the solutions you’re investing in. Are they committing you to a singular pathway, or are they flexible, giving you the power to choose and pursue multiple options? When you factor flexibility into your capacity expansion plans, you’re taking a large step towards futureproofing your facility.

Consideration three: established

When trying to minimize risk, you need a solutions provider that is proven.

“Reach out to some of these providers. Draw on their experience to bolster what you're doing,” offers Stapleton. “From a biotech space, you keep your antenna up constantly. You narrow who has technology that could advance what you're doing.”

Scalability and flexibility are two parts of the whole picture. But you need to minimize risk. So, when considering a solutions provider to aid in manufacturing capacity expansion, you need to ask: Is the provider established? From process development and manufacturing workflow equipment to advanced education and training for your staff, Cytiva’s enterprise solutions are dedicated to meeting the unique challenges of cGMP manufacturing of advanced therapies. Available for cell therapy, gene therapy, and bioprocessing applications, our FlexFactory™ platform has been installed at more than 100 sites across the globe, including:

- ElevateBio – cell therapy and viral vector manufacturing. The FlexFactory™ platform helped the company scale, close, and automate their manufacturing workflow – avoiding common capacity expansion issues along the way.

- Cellular Biomedicine Group Inc. (CBMG) – cell therapy manufacturing. The company incorporated the FlexFactory™ platform into this Shanghai facility to speed up manufacturing timelines for its cell therapy clinical trials and commercial launch.

- XPH – cell therapy manufacturing. Xiangxue Pharmaceutical Co., Ltd. (XPH) installed the FlexFactory™ platform, which helped them scale up, digitize, and accelerate manufacturing processes for their cell therapy clinical trials and future commercialization.

- Akron Biotech – plasmid manufacturing. The installation of the FlexFactory™ platform allowed Akron to alleviate constraints in the supply of a critical material — plasmid DNA — for cell and gene therapy manufacturing.

Your life-changing therapy could be the one that patients are waiting for. So, what are you waiting for? Start a conversation with us today.

- BioPlan Associates, Inc. Report and survey of biopharmaceutical manufacturing capacity and production, a study of biotherapeutic developers and contract manufacturing organizations. April 2021;18:432.

- Durdy, Matthew. Champions of Cell & Gene Therapy. The Medicine Maker. https://themedicinemaker.com/business-regulation/the-champions-of-cell-gene-therapy. Published February 24, 2022. Accessed June 1, 2022.

- BioPlan Associates, Inc. Report and survey of biopharmaceutical manufacturing capacity and production, a study of biotherapeutic developers and contract manufacturing organizations. April 2021;18:429.