HPLC pain points - part 1

High-performance liquid chromatography (HPLC) systems are widely used in analytical laboratories. Ensuring that systems are in good working order minimizes equipment downtime and increases lab efficiency.

Problems in an HPLC system can arise from several sources. The source of a given problem can often be identified by looking at the system itself or by checking downstream, by looking at the chromatogram.

Recognizing visible signs of in-system issues can identify potential problems and determine solutions that extend the usable lifetime of a column. Maximizing column lifetime has benefits in data quality, cost, and in reducing downtime.

What problems can occur in an HPLC system?

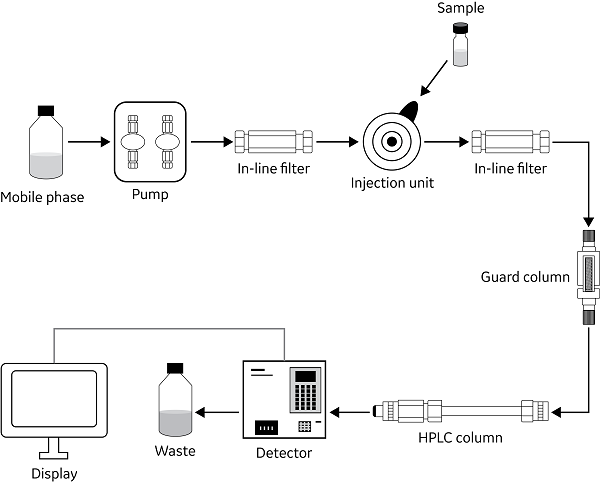

An HPLC system consists of multiple components, including an injector, flow path, pump, column, and detector unit.

A mobile phase (e.g., buffer) enters the system and passes through a pump that pressurizes the system. This mobile phase routes through to the injector to pick up the sample and carry it to the column. Both the sample and mobile phase are applied to the column for analyte separation before passing through the detector.

Problems occurring at any point in this path might influence the success of a run or affect the column quality and lifetime. Visible signs of issues from the HPLC system include:

- Increased back pressure

- Leakages and loss of pressure

- Inability to maintain a consistent flow rate

What causes these problems?

Particle contamination

Particles can make their way into an HPLC system via the sample or the mobile phase. These physical contaminants might be dust from the environment or other solids, such as precipitated protein and undissolved buffer components.

The result of physical contamination over time is two-fold:

- Blockages in the system, most likely at the HPLC column frit or the column itself.

- Wear and tear to the system components, including scratches, adding further particle contamination.

Increased back pressure is a clear indicator that part of the system is obstructed. The pump will try to maintain a fixed, accurate flow rate despite the blockage. But the instrument might eventually shut down to prevent damage.

Blockage of the column or frit also affects the uniformity of sample loading onto the column. These effects are visible from the chromatogram and explained in more detail in part 2 of the HPLC troubleshooting guide.

System components likely to suffer damage from particle contamination include injector valves, pump components, connectors, seals, and reciprocating parts. Depending on the location, damage might be visible as increased back pressure, leakages, or an inconsistent flow rate.

In addition to affecting quality of results, particle damage might require additional servicing/maintenance and column replacement. These delays and system downtime reduce lab efficiency.

Chemical contamination

Physical contamination of the HPLC system can build up over time to cause damage, resulting in the eventual need to replace columns and parts. However, chemical contamination has more immediate effects.

Some chemicals might bind irreversibly to the column, causing an increase in back pressure. Chemicals might also result in solubilization of the column resin, affecting separation and data quality. In both situations, the column will need replacing, which brings additional costs and equipment downtime.

Depending on the source of contamination, physical damage to the HPLC system and its components is another concern for users. This damage is also associated with equipment downtime and increased costs for replacement and servicing.

Dissolved gas

Although dissolved gas can be present in both the sample and the mobile phase, gas in the mobile phase generally causes many issues in an HPLC system.

If dissolved gas reaches the detector, bubbles can form as it comes out of solution, presenting as a drop in pressure. The interference from gas bubbles will be visible from the chromatogram. Part 2 of the HPLC troubleshooting guide covers these effects in more detail.

What solutions are available to minimize in-system problems?

Particle contamination is a common issue affecting HPLC system components.

Filtration of the sample and mobile phase can help to combat particle contamination by reducing blockages and the need to replace system components, including the column.

Filtering the mobile phase through a 0.45 µm filter can reduce particles entering the system.

There are many considerations for sample preparation and filtration, but it is generally straightforward to remove particulates using a syringe or syringeless filter device. Prefiltration or a multilayer syringe filter can be an effective option for thick or particulate-laden samples. Using a precolumn filter and guard column can also aid the removal of particles to minimize damage and increase lab efficiency.

Inherently, columns and other components of HPLC systems have limited lifetimes. Adjusting protocols to extend this usable lifetime can minimize the frequency of replacement while maintaining data quality throughout. Find out more in part 2 of the HPLC troubleshooting guide.

Try our Whatman filter selector to find out if you are using the most appropriate filtration solution for your samples. To discuss any challenges you are facing, please contact Cytiva's Scientific Support.