Custom immunoassay rapid test components

Getting optimal components designed into your immunoassay the first time is critical to success. Our custom services can meet your needs of optimized components when our off-the-shelf products don’t meet your exact design specifications. This is where Whatman™ custom services comes in. With deep expertise not only in component customization and manufacturing, but also in immunoassay design and development, we will help you find the right custom solution, with Whatman™ quality built in.

We have the expertise and capacity to produce custom cellulose and glass fiber substrates and nitrocellulose membranes to an assured quality, ensuring accurate and reproducible results.

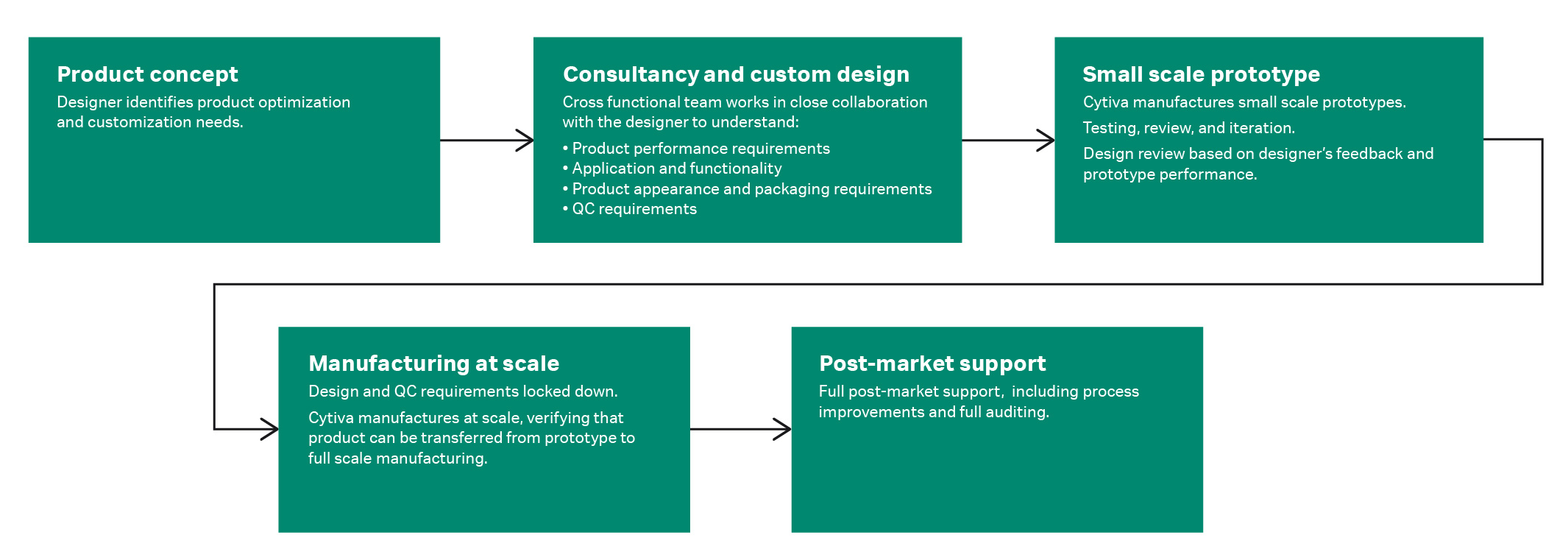

Custom design process

Using our rigorous customization methodology, we apply our expertise in test design, material selection, and scaling prototypes to manufacturing, to deliver success for you and help you get to market faster. We will work collaboratively with you from product concept to post-market support.

Custom capabilities

| Material |

|

|

| Manufacturing specifications |

|

|

| Conversion |

Cutting |

|

| Slitting |

|

|

| Punching |

|

|

| Treatment |

Controlled impregnation Acid treatment Lamination |

|