Simplifying and automating cell therapy manufacturing to help reach more patients.

Cell therapy may be a new field, but it’s rapidly advancing. CAR-T therapy, which uses a patient’s own re-engineered T-cells to find and kill cancer, is now treating patients in over 800 clinical trials, with the first of its kind now approved by the FDA.

The efficacy of treatments we’re seeing from this first generation of genetically modified immune cells is absolutely astounding,” said Dr. Aaron Dulgar-Tulloch, Director of Bridge, GE Healthcare. “Nothing is more exciting than 83% remission rates in patients who typically have a dismal prognosis [1].” Fewer than 10% of patients with relapsed and refractory acute lymphoblastic leukemia (ALL) survive five years.[2]But, the industry has a long way to go to get these therapies to more patients who need them. Cell therapy manufacturing today is complex, challenging and costly – it’s crying out for efficient technology, and scalable processes.

“Novartis’ recent FDA approval of its CD19-directed CAR-T product Kymriah further underscores the need for scalable solutions for CAR-T cell manufacturing to address the large global demand that will follow from this approval,” said Dr. Rohin Iyer, Development Manager of Bridge, GE Healthcare.

Often when developing new equipment, companies would listen to customer needs, and then go behind closed doors for a few years to try to build the perfect machine to introduce to the market. Because cell therapy has evolved so quickly, GE realized a conventional development approach wouldn’t suffice.

GE Healthcare’s cell therapy business set out to find a way to work hand in hand with customers by creating a cross-industry center of excellence. “We had to help customers move forward at the speed they require, and we also needed to put ourselves in their shoes so we could better understand their problems,” Dulgar-Tulloch said. “And in doing so, we can better and more collaboratively develop fixes to those challenges.”

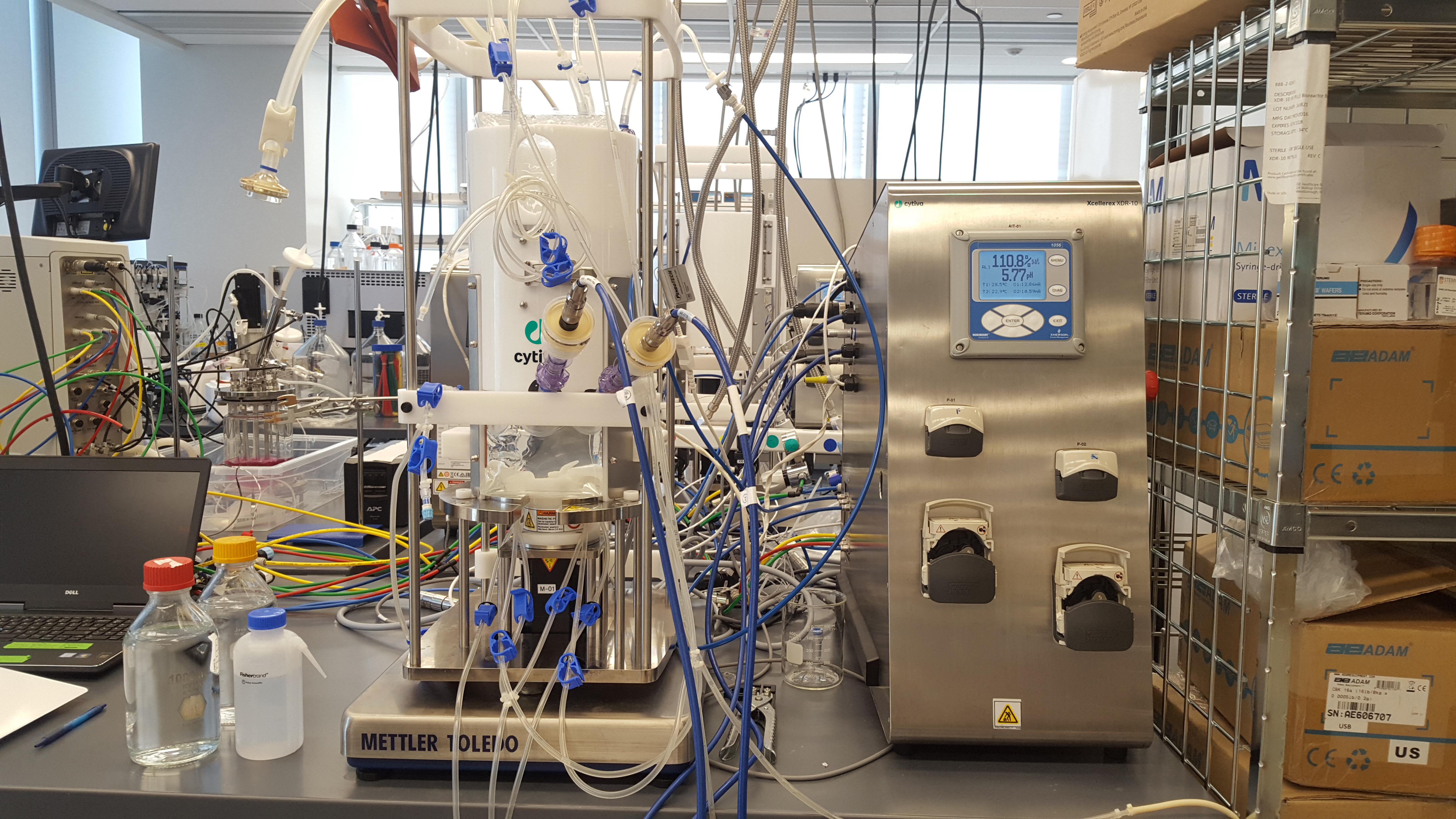

Image credit: CCRM

The solution was to launch the Centre for Advanced Therapeutic Cell Technologies (CATCT) in the MaRS Discovery District of Toronto with CCRM , a leader in developing and commercializing regenerative medicine technologies and cell and gene therapies. CATCT is jointly supported by GE Healthcare and the Federal Economic Development Agency for Southern Ontario (FedDev Ontario). And, it’s far from conventional.“CATCT is an experiment that’s paying off,” says Dr. Michael May, President and CEO of CCRM. “This is our largest industry collaboration to-date and GE has been the ideal partner. We both want to see the regenerative medicine sector succeed, and thrive, and we’re combining our areas of expertise to make sure our funders, shareholders, industry partners and customers are all happy. At the end of the day, we both want to develop products and therapies to cure patients.”

Within the facility, there is a team called Bridge consisting of 40 employees from both GE Healthcare’s cell therapy business unit and CCRM, working together in a 10,000-square foot state-of-the-art lab to address the many challenges associated with cell therapy manufacturing.

“The emphasis on automation, scalability and patient safety is key to enabling global dissemination and access to these highly efficacious therapies,” said Iyer.

The Bridge team is developing an upstream process that routinely allows for the expansion of tens of billions of T-cells in GE’s Xuri W25 Cell Expansion System using xeno-free and animal component-free reagents. The scientists and engineers who work on the Bridge team are also evaluating several novel cryopreservation reagents and strategies to enable “off-the-shelf” thawing and infusion of T-cells.

Inside CCRM’s Toronto labs, scientists are paving the way for new applications for different cell types. They are pioneering the manufacturing-scale production of pluripotent stem cells, cells that can turn into any kinds of cell – in bioreactors. For instance, they have a process that enables pluripotent stem cell culture in a stirred-tank bioreactor system, leveraging GE’s Xcellerex platform.

“Now that we’ve got a good handle on blood cancers with CAR-T, the next big opportunity is making this work for other applications such as solid tumors,” Dulgar-Tulloch said. “If we can do that, this will be a totally new field for cancer treatments compared to where we are today.”

[1] https://www.fda.gov/biologicsbloodvaccines/cellulargenetherapyproducts/approvedproducts/ucm573706.htm

[2] Ronson, A., Tvito, A., Rowe, JM., “Treatment of Relapsed/Refractory Acute Lymphoblastic Leukemia in Adults.” Current Oncology Reports, 2016 Jun;18(6):39. https://www.ncbi.nlm.nih.gov/pubmed/27207612. Accessed October 10, 2017.

Originally published on GE Healthcare’s The Pulse http://newsroom.gehealthcare.com/race-to-market-collaborating-to-accelerate-cell-therapy/