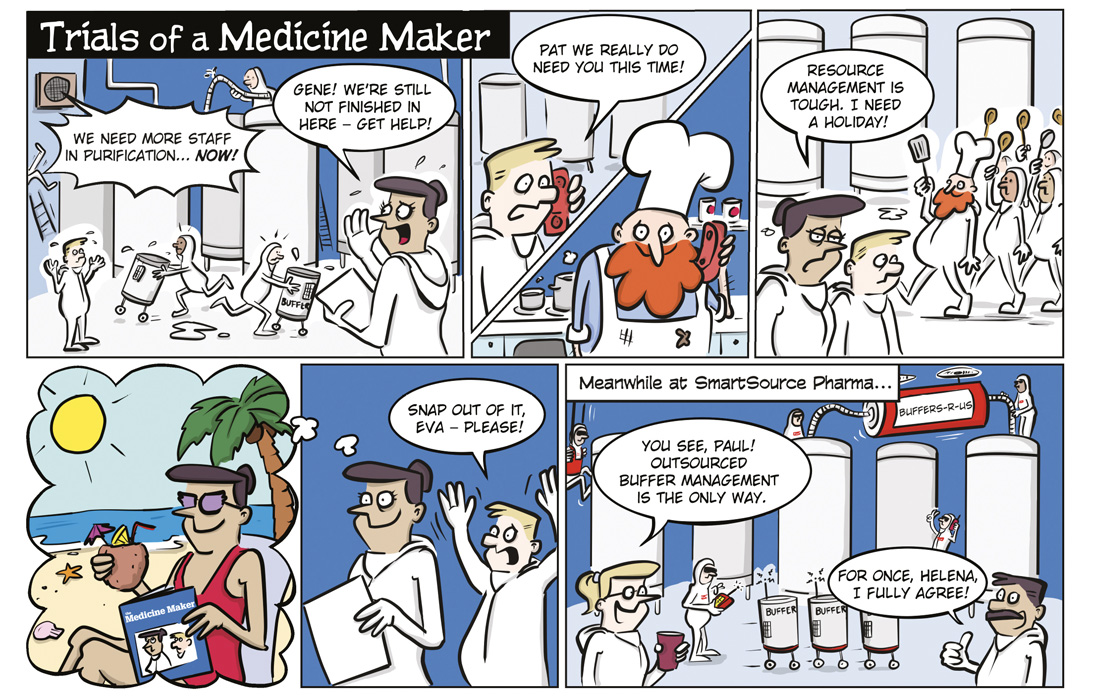

Medicine maker Eva should certainly learn some tips from Paul and Helena who called ‘Buffers R Us’ for help.

Eva wishes she was on vacation, but she knows her team would struggle with buffer management without her. The problem is, as biomanufacturing titers go up, so do downstream buffer volumes.

Buffer preparation is one of the most resource-intensive activities in biomanufacturing due to the large number and overall volume of buffers and process liquids used in a typical bioprocess workflow. As a result, buffer preparation can be prone to create bottlenecks in the manufacturing process. So how do you expand capacity in buffer management?

There are different approaches, to drive change in biomanufacturing; you can outsource this step, or take advantage of new technologies such as in-line conditioning (IC) and in-line dilution (ILD). These methods can be used to reduce the total volume of the stock solutions up to 79% and the total footprint of the buffer management system and tanks by 40% over traditional buffer preparation.

Read this article to learn about buffer management solutions for large-scale biomanufacturing.