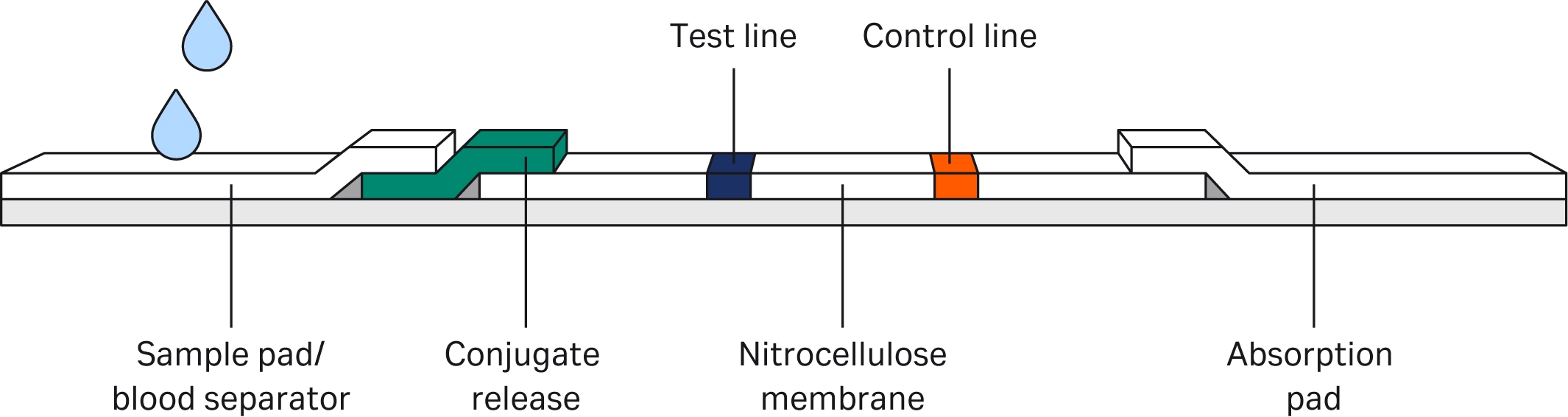

Absorption pads at the downstream end of tests control sample flow along the strip. Cytiva has developed pads with excellent wicking characteristics that ensure consistent performance. Choosing an absorbent pad with sufficient capacity is an important consideration when designing an immunoassay. In a lateral flow assay the absorbent pad or wick is the component which is located on the end opposite to the sample application zone. Its primary function is to act as a sink for the reagents. If a lateral flow device does not have an absorbent pad the flow stops as soon as the front has reached the distal end of the reaction membrane. In this case the sample volume that can be analyzed is defined by the void volume of the membrane (i.e. membrane length x width x porosity). Adding an absorbent pad can substantially increase this volume. A typical effect in lateral flow assays is that the direction of flow reverses when the membrane starts to dry after the assay has ended. The liquid has been collected by the absorbent pad which now starts to act as the source. This backflow effect often causes false positive results when the assay is read too late.

Whatman offers a variety of cellulose and glass fiber materials as well as cellulose-glass fiber blends to ensure that all sample types and specific needs can be addressed. CF3, CF4, CF5 and 470 are medium weight grades which can accept medium and larger volumes. CF7 is a very thick grade for high sample volumes.

Features and benefits:

- Consistent absorbency: Ensures test-to-test reproducibility

- Product manufactured in controlled environments from highest-quality materials: No false results due to contamination

- Naturally hydrophilic: Minimal loss of analyte, so test sensitivity is maintained

- Wide range of thickness, absorbency and wicking rate: Rapid rewetting after prolonged storage

- Minimal leakage along the strip: No contamination of test results

Key considerations:

- Thickness: thickness rates are so great here that sometimes it goes beyond commercially available cassette housings – prime influencer. This is a key consideration. Don’t compress the wick (essentially a sponge) which will then decreases it’s absorption capacity and breaks the test.

- Wicking rate: the faster the wicking rate, the faster the absorption kinetic for the sample which impacts the speed of whole test. If the absorption kinetic is too fast, the interaction time at test/control lines is reduced.

- Water absorption: has to quickly absorb sample. Capacity must be much larger than the sample volume since it both absorbs sample liquid and prevents backflow onto the membrane. This generally requires very thick papers.

| Grade | Properties | Thickness (um @ 53kPA) |

Wicking rate (s/4cm) |

Water absorption (mg/cm2) |

|---|---|---|---|---|

| CF3 |

A medium thick cotton linter paper, originally used for separation of inorganic compounds. Larger sample volume than CF1. |

322 |

174.3 |

34.6 |

| CF4 |

A medium thick cotton linter paper with acid treatment to improve wet strength and reduce trace impurity content. Similar weight and thickness to CF3 with faster wicking. |

482 |

67.3 |

49.9 |

| CF5 |

100% cotton linter can handle medium/high volumes |

954 |

63.3 |

99.2 |

| CF7 |

100% cotton linter can handle medium/high volumes |

1873 |

35 |

252.3 |

| GR470 |

Untreated bound glass fiber suitable for whole blood or serum. |

840 |

77 |

78 |

For samples or to contact a specialist

RELATED CONTENT

- Component selection in lateral flow assay development (blog)

- Membrane selection for lateral flow immunoassays (article)

- Custom lateral flow assay projects (article)

- Lateral flow assay troubleshooting guide & how to switch diagnostic membranes (article)

- Infographic: Considerations for lateral flow membrane selection

- Infographic: 10 Top Tips for lateral flow assay development

- Infographic: Navigating flow-through assays