Alligator Bioscience AB develops antibody-based pharmaceuticals for cancer treatment, specializing in mono- and bispecific antibodies for tumor-directed immunotherapies. The company is active in the early stages of drug development, from early concepts to clinical phase II studies.

This article shows the results from our collaboration with Alligator to develop an efficient downstream purification process for a cancer immunotherapy bispecific antibody (bsAb). The main findings of the study were:

- Exchanging MabSelect SuRe™ to the more recently developed MabSelect PrismA™ resin increased the loading capacity by 53% (using a load of 70% of the Qb10 for MabSelect PrismA™).

- The stability of the bsAb in respect to pH and salt limited the window of usable conditions for the polishing step, but conditions could be optimized for purification on Capto™ adhere in both bind/elute (B/E) and flow-through (FT) mode.

- The evaluated conditions for elution from Capto™ adhere were considered good conditions for the B/E application in respect to the stability of the bsAb.

- Using the same conditions for the polishing step—but in FT rather than for elution in B/E mode — improved yield significantly (> 90% yield) with acceptable HCP levels and protein A clearance.

- The improved process both increases product yield and process economy.

Introduction

Bispecific antibodies (bsAbs) have gained increasing interest over recent years because they can bind two antigens, offering unique modes of action compared to monoclonal antibodies. New and improved antibody bioprocesses and recombination techniques have contributed to a surge in the numbers of bispecific antibody constructs currently in clinical trials. As of 2019, one bsAb has been approved and 57 bsAb are in clinical trials (1).

There are many types of bsAb formats with two different sites to target different antigens. This dual specificity of bsAbs means that they can, for example, bind to target cells using one antigen-binding site and recruit other cells or molecules with the second antigen-binding site.

When it comes to purification of Fc-containing bsAbs, manufacturers typically use a platform approach based on protein A chromatography for capture of the antibody. The subsequent polishing steps are added to obtain a product of desired final product quality.

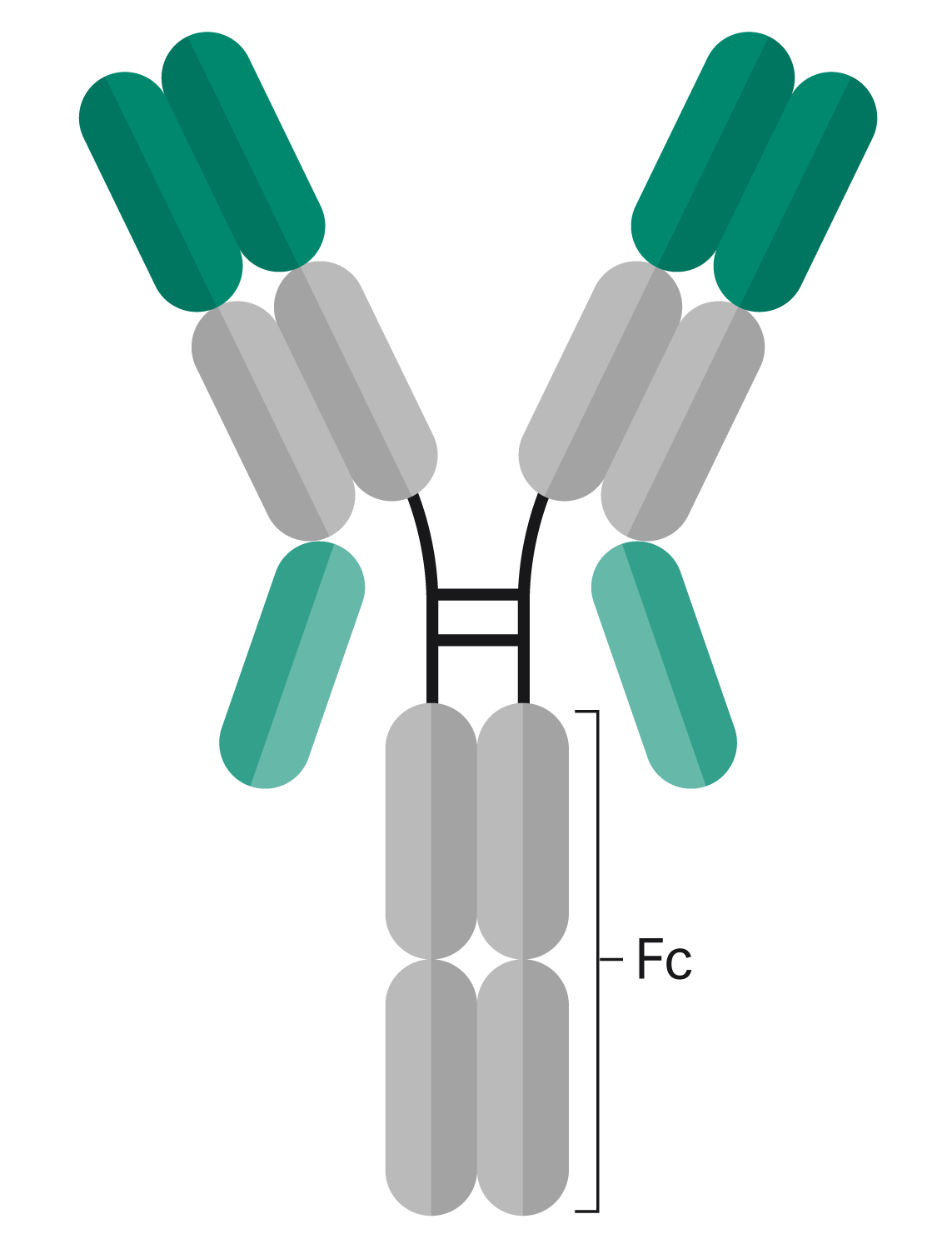

This article describes the further development of a two-step purification of a bsAb. The original MabSelect SuRe™ capture step was exchanged to MabSelect PrismA™ to increase the process economy. The bsAb used in this study is an anti-tumor, human IgG1 symmetric bispecific antibody, see Figure 1 for the bsAb format.

Fig 1. The bsAb format for the antibody used in this study. A recombinant protein is attached c terminally to the light chain (light green), thereby creating a second binding domain. The Fc part of the antibody is a fully human IgG1 without any further modifications.

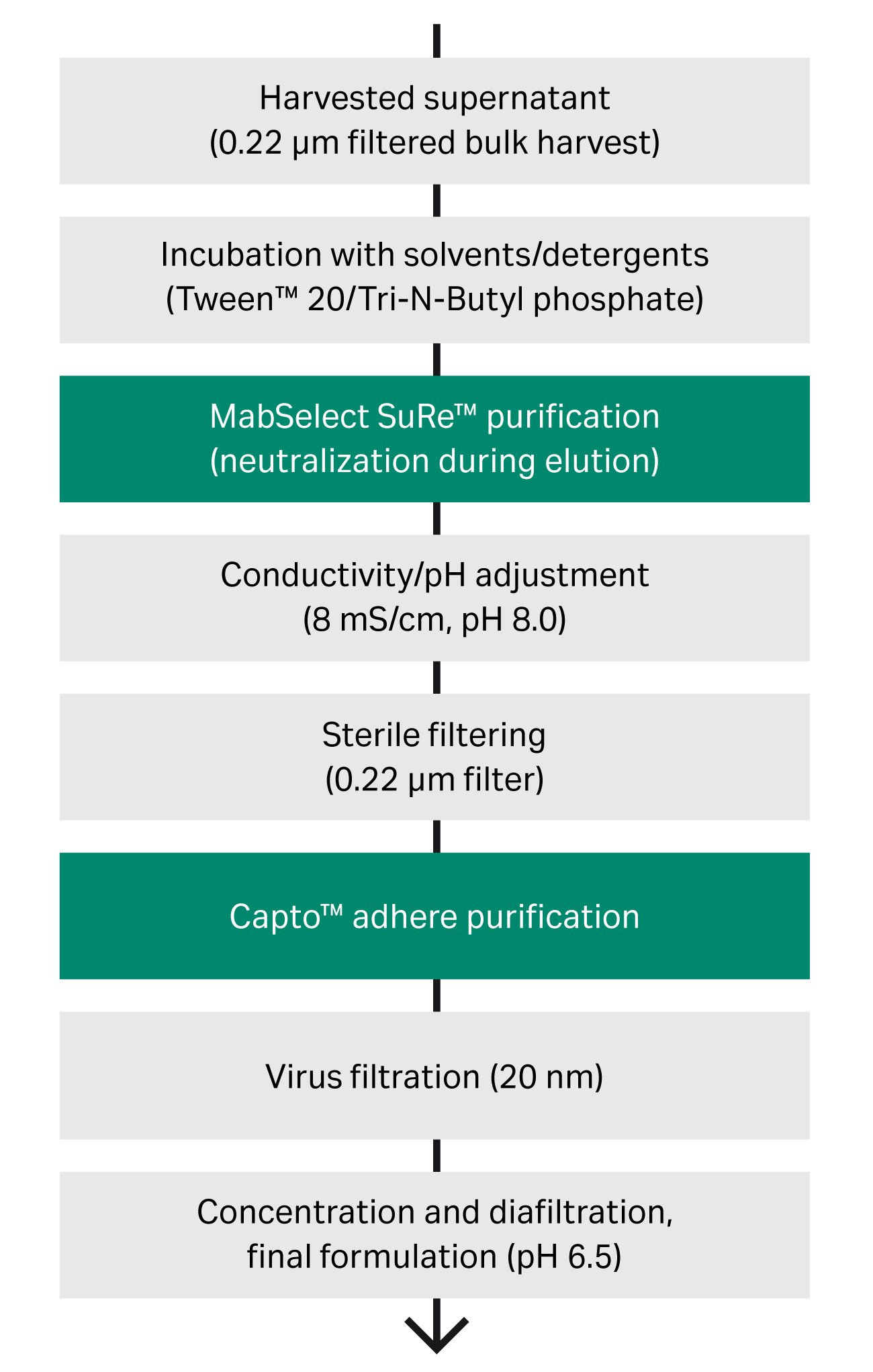

Current purification process based on MabSelect SuRe™

The original downstream process for purification of the bsAb was based on a platform commonly used for regular monoclonal antibodies (mAb) except that the traditional low pH virus inactivation step was replaced by a solvent detergent step due to the pH sensitivity of the antibody. To immediately increase the pH after elution from MabSelect SuRe™, the elution pool was collected in a vessel pre-prepared with 200 mM sodium phosphate buffer, pH 6.9. Figure 2 shows a schematic view of the original process.

Fig 2. Original downstream process for the purification of the bsAb.

Evaluating capture of the bsAb with MabSelect PrismA™

Despite the high yield and purity obtained using MabSelect SuRe™ in the original process, our more recent protein A resin — MabSelect PrismA™ — was evaluated as a potential replacement, with the aim of further improving the process economy.

As early research material with a non-optimized cultivation yield was used as input for the experiment, the titer of the clarified harvest was low (0.8 g/L). The residence time (RT) was therefore set to 4 min rather than 6 min as recommended for MabSelect PrismA™ to shorten the step during process development. Frontal analysis at 4 min RT showed that the dynamic binding capacity (DBC) at 10% breakthrough (Qb10) for MabSelect SuRe™ and MabSelect PrismA™ was 42 and 64 g/L of resin, respectively.

A modified capture step using MabSelect PrismA™

Viral inactivation was performed with Tween™ 20 and Tri-N-Butyl phosphate at neutral pH. The supernatant provided by Alligator containing the target bsAb was treated for 90 min with the viral inactivation solution at room temperature. After inactivation, we adjusted the pH to 7.0 with 0.5 M NaOH and filtered the virus inactivated supernatant through a 0.22 µm filter.

Our goal for testing MabSelect PrismA™ was to investigate if we could increase the loading capacity compared to MabSelect SuRe™.

Based on the breakthrough capacities, the load was set to 45 g of bsAb/L of MabSelect PrismA™ corresponding to 70% of Qb10.

Runs were repeated at different scales, starting with a Tricorn™ 5/100 column (CV = 2 mL) packed with MabSelect PrismA™, which resulted in a bsAb yield of 87%. Scale-up to a wider Tricorn™ 10/100 column (CV = 7.4mL) gave a yield of 91%. Finally, as more material was needed for the polishing step, the capture step was performed in a larger HiScale™ 16/20 column (CV = 24 mL), which gave a yield of 95%. Increasing yield when increasing the size of the column is a typically observed in downstream processing.

Eluted fractions were collected into a 50 mL tube prepared with 0.3 to 0.4 CV of a 200 mM sodium phosphate neutralization buffer, pH 6.9 to maintain bsAb integrity.

The conditions for the improved capture step are detailed here:

| Columns: |

Tricorn™ 5/100 (CV = 2 mL); Tricorn™ 10/100 (CV = 7.4 mL); HiScale™ 16/20 (CV = 24 mL) packed with MabSelect PrismA™ resin |

| Sample: |

Cell culture supernatant containing bsAb and added viral inactivation solution |

| Column load: |

70% of Qb10 (45 g/L) |

| Equilibration: |

10 mM sodium phosphate, 150 mM NaCl, pH 7.0, 3 CV |

| Wash: |

10 mM sodium phosphate, 150 mM NaCl, pH 7.0, 7 CV |

| Elution: |

100 mM glycine-HCl, pH 3.2, 8 CV (eluate peak collected from 90 to 72 mAU) |

| Re-equilibration: |

10 mM sodium phosphate, 150 mM NaCl, pH 7.0, 3 CV |

| Flow velocity: |

4 min RT |

| Cleaning in place (CIP): |

0.5 M NaOH, 3 CV, 5 min RT |

| Detection: |

A280 nm |

| System: |

ÄKTA pure™ 25 |

Evaluation of Capto™ adhere polishing, bind/elute mode

We first performed the polishing step in B/E mode with Capto™ adhere using the conditions from the original downstream process. When using this approach, the target molecule binds to the ligand coupled to the resin through mixed-mode interactions. Subsequent changes in pH releases the molecule from the resin to allow collection of the eluate.

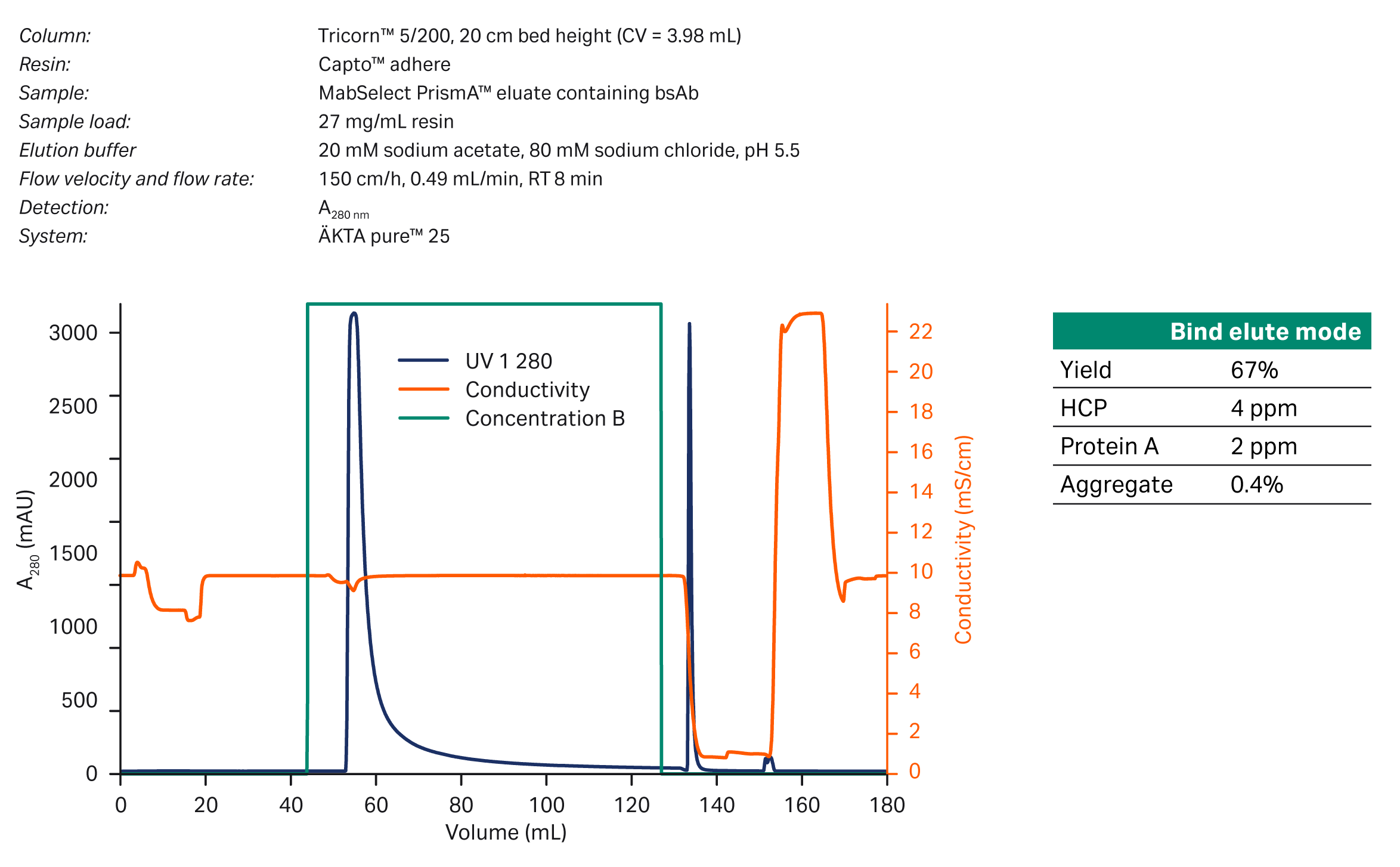

The resin used was Capto™ adhere packed in a Tricorn™ 5/200 column with a 20 cm bed height. MabSelect PrismA™ purified bsAb was buffer exchanged to 10 mM sodium phosphate, 80 mM sodium chloride pH 7.4. Sample was loaded at 27 mg of bsAb/mL resin. Eluate between 324 and 297 mAU was collected for analysis. Yield was calculated to 67% while levels of HCP (4 ppm), leached protein A (2 ppm), and aggregate (0.4%) were all well below the specifications set at the beginning of the study (Fig 3).

Fig 3. Chromatogram of the Capto™ adhere polishing step in B/E mode. The table shows that 67% yield of the bsAb was achieved.

Stability test of bsAb in the Capto™ adhere polishing step

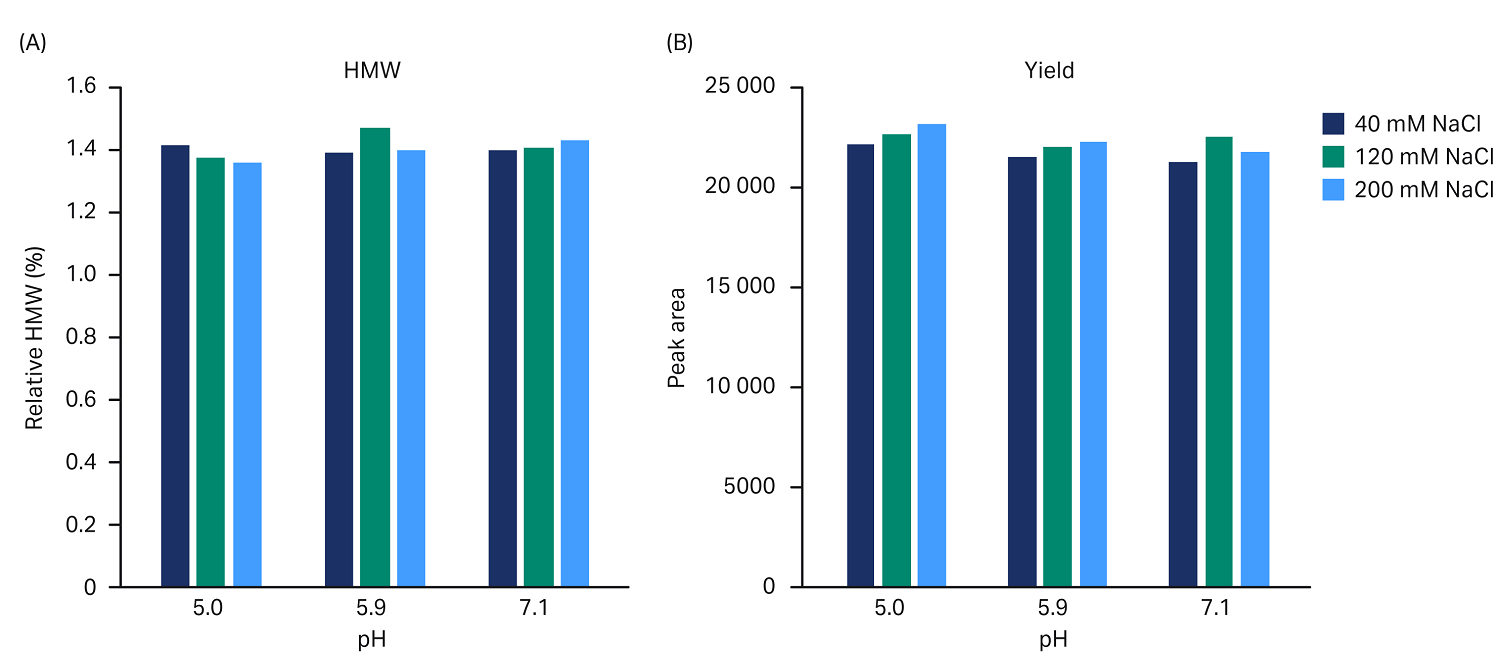

To improve the Capto™ adhere step, we evaluated the stability of the bsAb using the extreme buffer conditions in terms of pH and salt. From that study, we identified pH range between pH 5 and 7.1 in the presence of 40 to 200 mM NaCl where stability of the bsAb could be expected. The purified bsAb (20 mg/mL) was diluted on a 96-well plate to a concentration of 4 mg/mL with nine different buffer conditions within the range above. Samples were incubated for 2 h on a shaker.

The yield was estimated by comparing areas of the start sample to areas from samples analyzed by size exclusion chromatography (SEC). We observed no effect on aggregate level or yield at the selected conditions (Fig 4).

Fig 4. Comparison of (A) aggregate levels and (B) yield of bsAb treated for 2 h in phosphate buffers at: pH 5.0, 5.9, and 7.1 and with three salt concentrations: 40, 120, and 200 mM NaCl.

Polishing step: screening experiments

Capto™ adhere can also be used in flow-through (FT) mode where impurities bind to the resin while the target molecule is collected in the chromatography flowthrough. An FT process usually gives better process economy as the load can be significantly higher than for B/E mode.

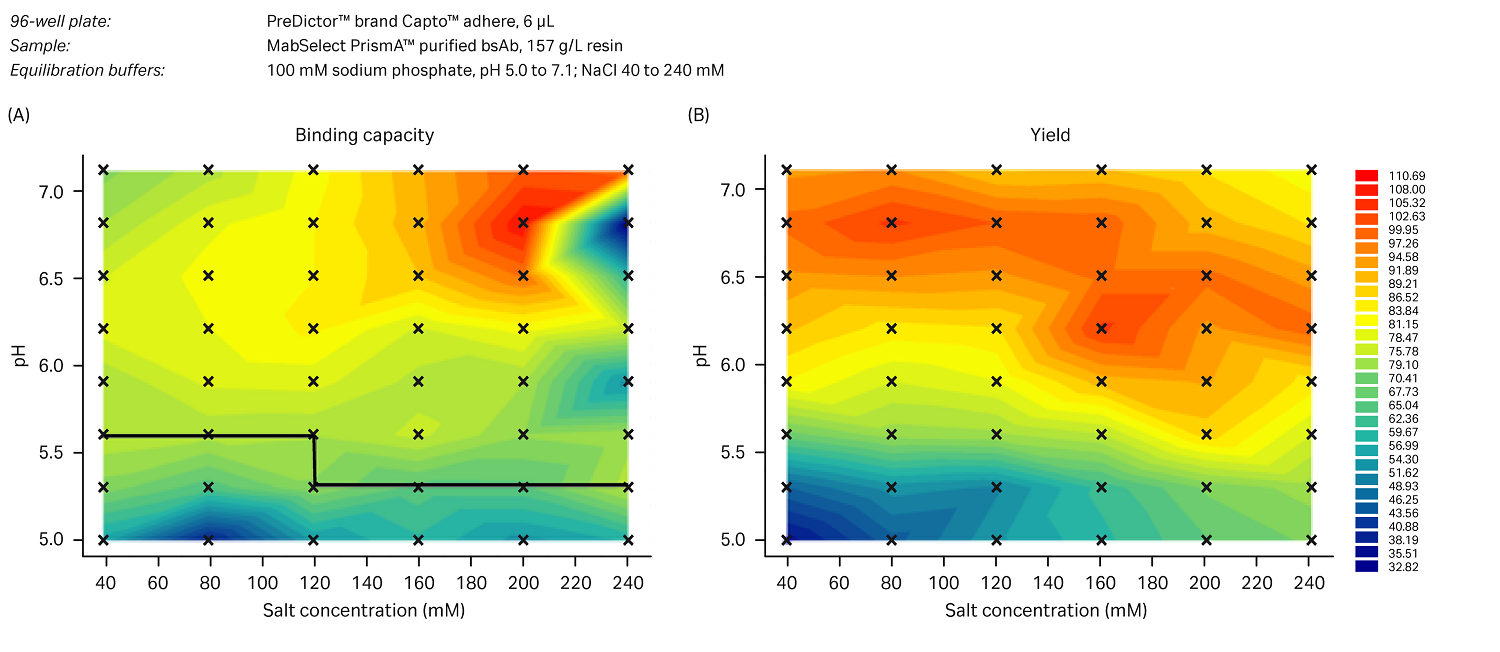

To improve process yield and process economy, we evaluated a potential FT method using 96-well PreDictor plates filled with 6 µL of Capto™ adhere. The process development was designed to find optimal chromatographic conditions under non-binding conditions, with high product yield and HCP levels below target as high-molecular weight (HMW) content was already within specifications.

The equilibration buffers tested were composed of 100 mM sodium phosphate with pH from 5.0 to 7.1 and NaCl concentrations from 40 to 240 mM. The wells were equilibrated with 3 × 200 µL of equilibration buffer and sample load was set to 157 mg/mL resin, a load that could also be applied in a FT step. The plate was then incubated on an orbital shaker for 60 min at 1100 rpm and then emptied into a UV plate with centrifugation at 500 × g for 1 min. The absorbance was read by using a UV reader.

Results for the binding capacity of the bsAb are shown in the heatmap in Figure 5a and HCP concentration is shown in Figure 5B.

Fig 5. Binding capacity of bsAb (A) where blue indicates the lowest binding capacity (i.e., most suitable for an FT application) and red the highest. The marked area shows the conditions where HCP levels are < 100 ppm, which was the threshold value set for the study. The yield of HCP in percent is shown in (B) where blue gave the best clearance of HCP. From the plate experiment, two conditions were selected: 40 mM NaCl, pH 5.0 and 80 mM NaCl, pH 5.5 for FT in column, both having good clearance of HCP and low binding capacity for bsAb.

From the plate experiments, we observed that the HCP clearance was improved in the lower pH/salt-range. However, in the earlier stability screening, we observed that below these conditions the bsAb showed stability issues. Thus, we decided to compare the apparent best condition from the PreDictor™ plate study (40 mM NaCl, pH 5.0) with a more robust condition from a process perspective (80 mM NaCl, pH 5.5). The pH 5.5 condition is identical to the elution condition used in the original process where Capto™ adhere is operated in B/E mode.

Column studies of polishing step with Capto™ adhere in flow-through mode

The sample from the MabSelect PrismA™ capture step was buffer exchanged to loading buffer before start and Capto™ adhere chromatography at the two conditions stated above.

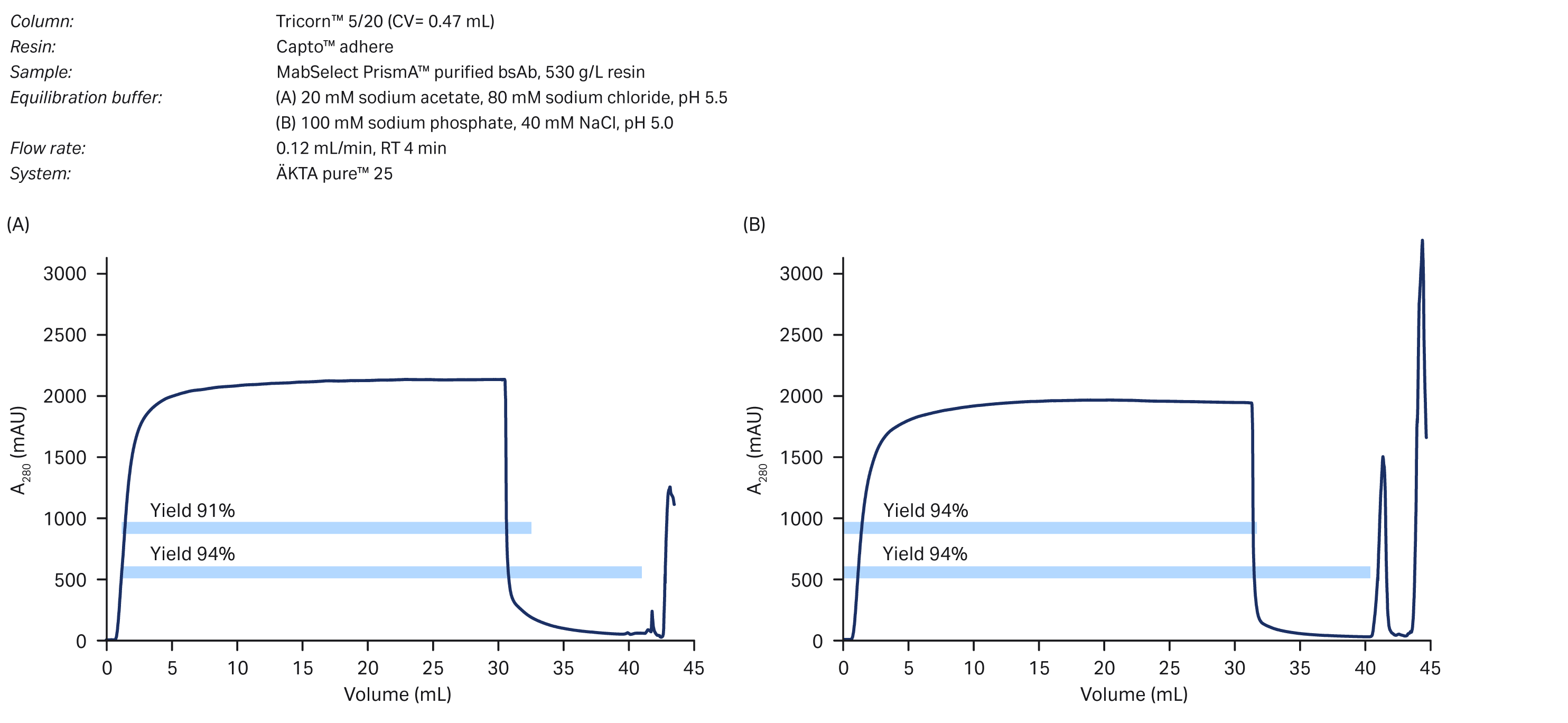

Fig 6. Polishing purification in FT mode of bsAb on Capto™ adhere using (A) 20 mM sodium acetate, 80 mM sodium chloride, pH 5.5 and (B) 100 mM sodium phosphate, 40 mM NaCl, pH 5.0. The lower bars show yields with the wash fraction included while the upper bars show yield without wash fractions.

Yield from the polishing was over 90% for both FT methods. A significantly higher yield of 94% was observed for FT mode compared to the original B/E process (see Fig 3) with a yield of 67%.

Analysis of aggregates, HCP, and leached protein A

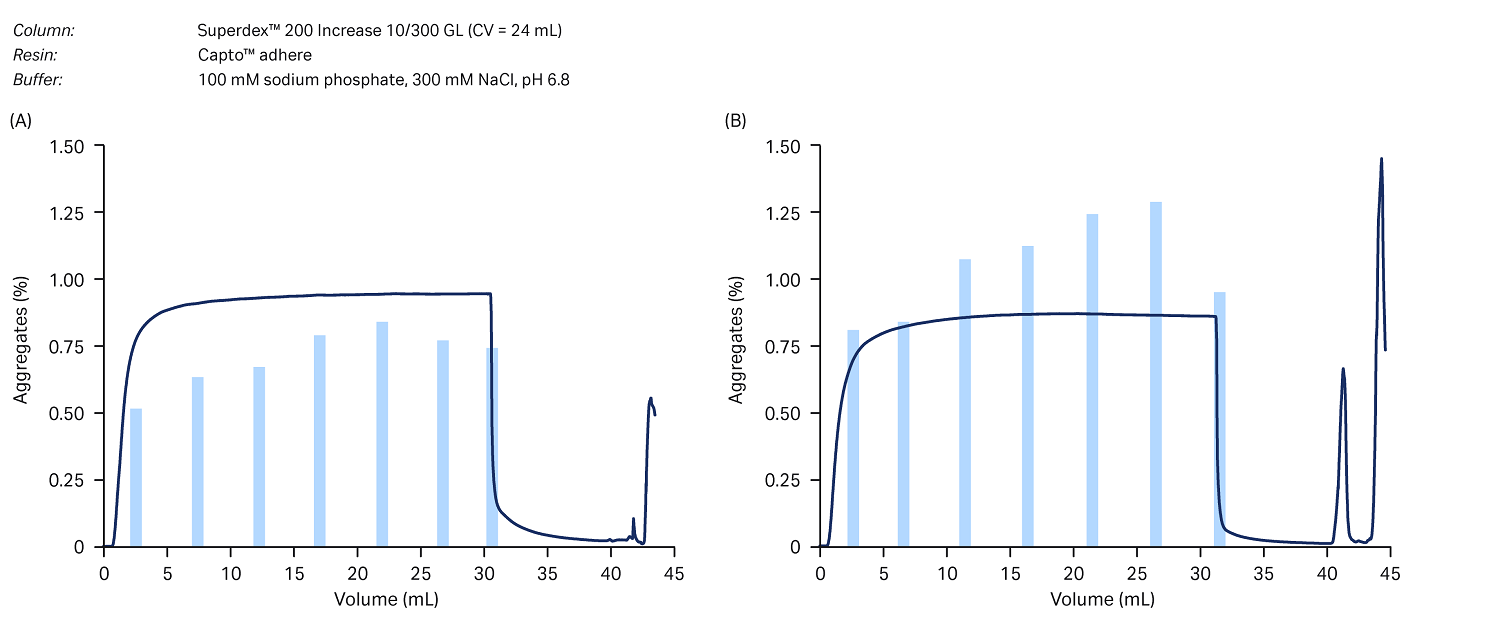

Size exclusion chromatography (SEC) using a Superdex™ 200 Increase 10/300 GL (CV = 24 mL) was used to analyze aggregate levels.

The aggregate content in the start sample from the MabSelect PrismA™ capture was already low at about 1%. The Capto™ adhere steps succeeded to further reducing the aggregate content to < 1%. (Fig 7). The aggregate content for selected fractions in the respective chromatography runs are shown in the bars in each chromatogram and are within the specifications set for this study.

Fig 7. Aggregate analysis using size exclusion chromatography from (A) the Capto™ adhere FT run at 20 mM sodium acetate, 80 mM sodium chloride, pH 5.5 and (B) 100 mM sodium phosphate, 40 mM NaCl, pH 5.0.

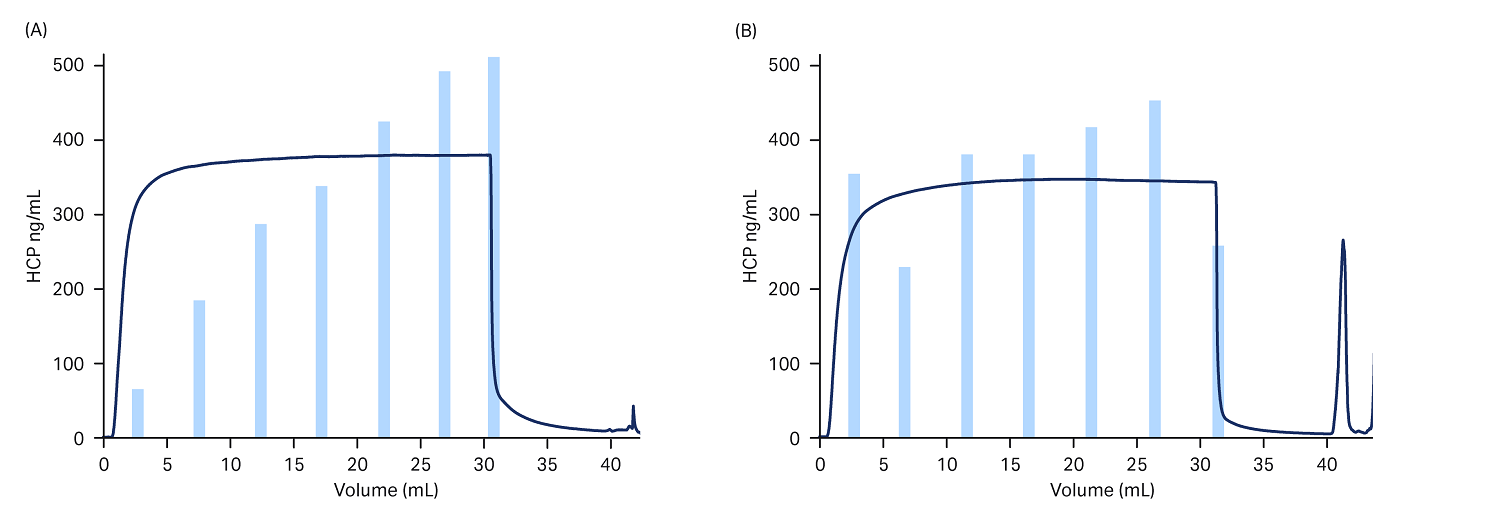

The concentration of HCP in start samples and the eluate from the B/E elution buffer run, in pooled fractions from the FT buffer run, and in selected fractions from the FT buffer run were analyzed using Cygnus technologies third generation CHO HCP ELISA reagents adapted to Gyrolab™ workstation (Gyros™ Protein Technologies), (Fig 8).

Figure 8A clearly shows an increasing HCP concentration (ng HCP/mL) with loading the FT buffer run at pH 5.5 (11 to 110 ppm). In the load at pH 5.0 (Fig 8B), the HCP concentration is more evenly distributed through the sample loading step. The HCP amounts were about the same in the two pools collected — 48 and 53 ng HCP/mg bsAb for pH 5.5 and 5.0 respectively — which is below the original specification of 100 ng HCP/mg bsAb set for this study. Also, the wash fraction may be included in the pool as this fraction made only a minor contribution to the HCP level and has no significant influence on protein A or HMW content.

Fig 8. HCP concentrations in selected fractions from the (A) 20 mM sodium acetate, 80 mM sodium chloride, pH 5.5 (B) 100 mM sodium phosphate, 40 mM NaCl, pH 5.0 were analyzed by Gyrolab™ workstation (Gyros™ Protein Technologies).

The purification results for the bsAb from Alligator are summarized in Table 1 and 2. Comparing mode of operation, (FT vs B/E) shows improved yield at the cost of lower HCP clearance. As similar results are obtained at both FT conditions, we conclude that the FT approach is robust. To avoid stability issues, the step should be operated at a pH above 5.0, that is the conditions used for elution in B/E mode is preferred also in FT.

Table 1. Results from the capture step with MabSelect PrismA™ and polishing step with Capto™ adhere

| Capture step with MabSelect PrismA™ | Load 70% of Qb10 => 45 g/L resin |

|||

|---|---|---|---|---|

| Yield |

93% |

|||

| In elution pool: |

HCP 131 ppm |

|||

| Protein A: 11 ppm |

||||

| Aggregate: 0.8% |

||||

| Polishing step with Capto™ adhere |

B/E |

FT pH 5.5 |

FT pH 5.0 |

|

| Yield |

67% |

91% |

94% |

|

| Purified/mL resin |

18 mg |

485 mg |

495 mg |

|

| HCP |

4 ppm |

48 ppm |

53 ppm |

|

| Protein A |

2 ppm |

3 ppm |

3 ppm |

|

| Aggregate | 0.4% |

0.7% |

1.1% |

|

Table 2. Overall yield

| Yield MabSelect PrismA™ |

93% |

93% |

93% |

|---|---|---|---|

| Capto™ adhere |

B/E |

FT pH 5.5 |

FT pH 5.0 |

| Yield |

67% |

91% |

94% |

| Overall yield |

62% |

85% |

87% |

Conclusions

This study concluded the following:

- Switching the capture step from MabSelect SuRe™ to MabSelect PrismA™ allowed a 53% increase in sample load at 4 min RT. This could probably be further improved at longer RT as the breakthrough curve indicated faster kinetics on MabSelect PrismA™ compared to MabSelect SuRe™.

- The optimized conditions for polishing were considered suitable for the FT application in respect to stability of the bsAb.

- The conditions applied in FT polishing mode also improved yield significantly (above 90% yield), but still with acceptable HCP and protein A clearance. This provides the potential for improved process economy.

- The two conditions compared for FT polishing mode resulted in similar yield and purity and we have good reason to believe that the FT mode and conditions are robust.

References

- Surs, F.V. et al. A review of bispecific antibodies and antibody constructs in oncology and clinical challenges. Pharmacol. Ther. 201: 103–119 (2019). https://doi.org/10.1016/j.pharmthera.2019.04.006