Our position on sustainability

At Cytiva, we believe that single-use products offer you fast, efficient, economical biopharmaceutical production. We also believe that the right way to do business is to do it sustainably. Although it might seem counter intuitive, single-use and sustainability go hand in hand.

Are single-use products good for the environment?

The simple answer? Usually. There is a very good chance that you can significantly reduce your carbon footprint, energy, and water use by switching from traditional stainless steel equipment to single-use products.

The evidence shows that the life cycle environmental impacts of single-use are lower than those for stainless steel across a range of impact categories. These categories include climate change, cumulative energy demand, freshwater consumption, human health, natural resources,and ecosystem quality.

The evidence for single-use sustainability

These perhaps unexpected sustainability results come from a third-party reviewed life cycle assessment (LCA) study performed in accordance with ISO standards. The study investigated products used at every stage of biopharmaceutical production, both at different usage scales and in different locations.

How an LCA study works

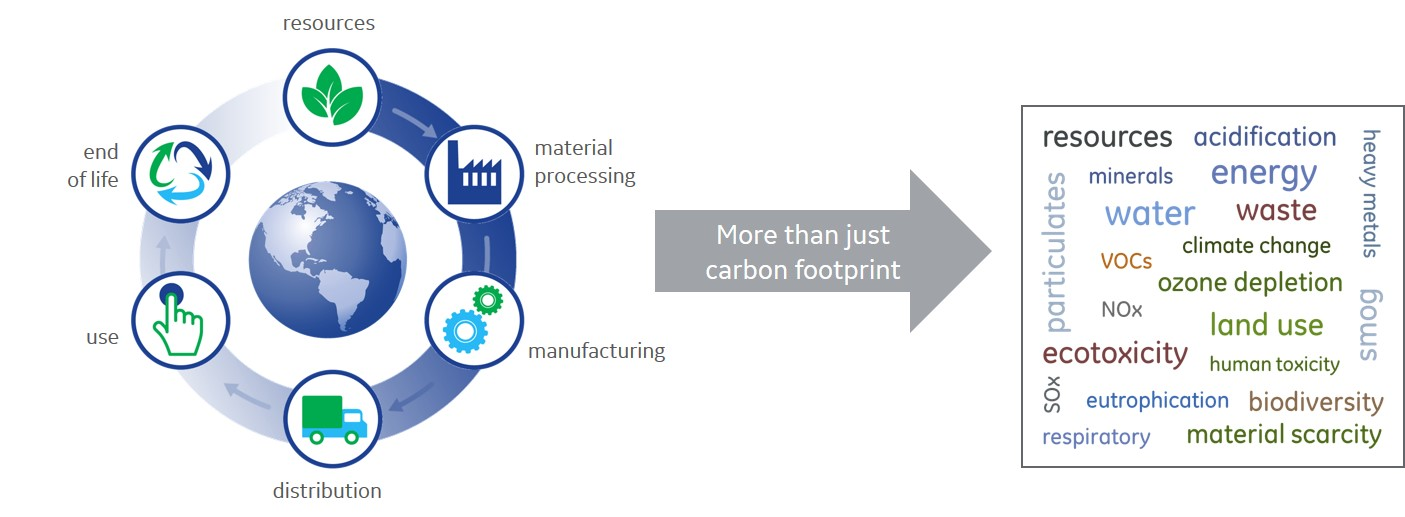

LCA evaluates environmental impacts, benefits, trade-offs, and burden shifts across the product life cycle.

- We collected data about all of the inputs and outputs (energies, masses, activities, equipment, transport) –known as the Life Cycle Inventory (LCI).

- We converted the LCI data into environmental impacts.

- We combined the impacts into damage categories.

Impact and damage categories

In this study we focused on three impact categories and three damage categories.

Impact categories:

- carbon footprint

- energy footprint

- water footprint

- human health

- ecosystem quality

- natural resources

What causes the most resource consumption?

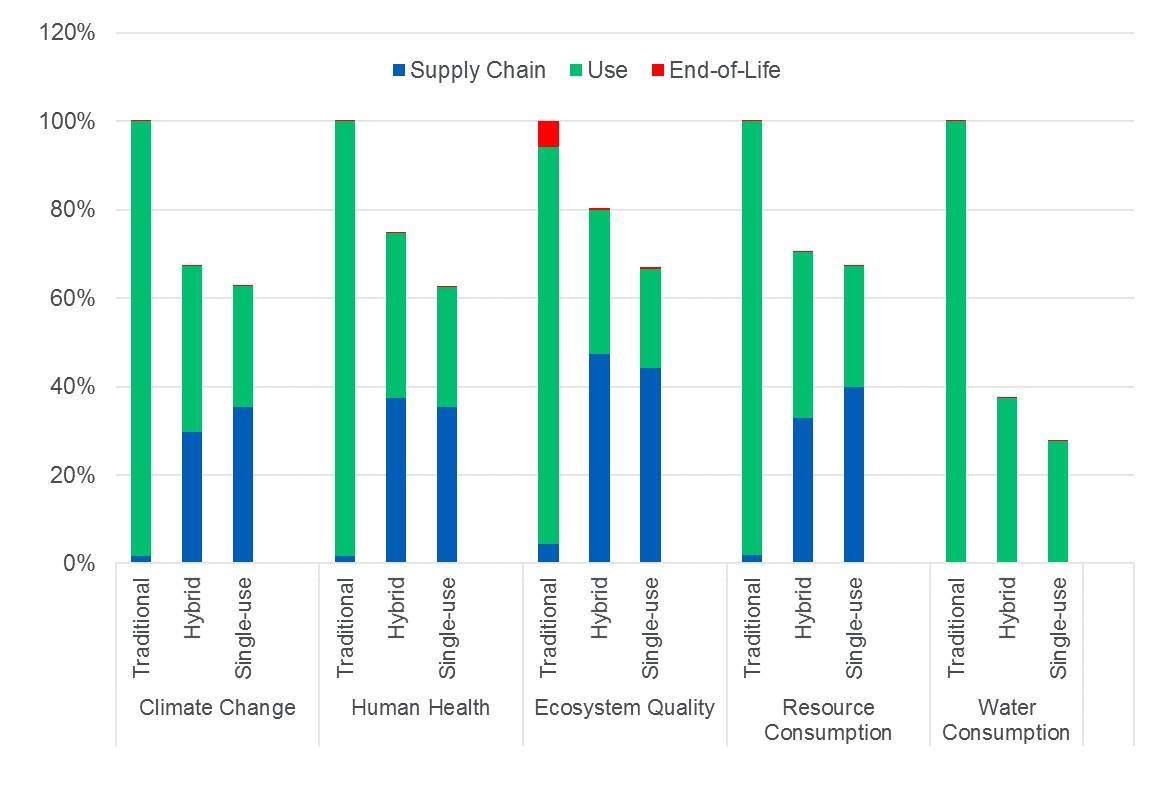

When people are concerned about the sustainability of single-use products, what they are usually thinking about is the waste being thrown away. In fact,the LCA study showed that end-of-life disposal is a minimal contributor to the overall environmental impact of single-use process technology (Fig 1).

For single use products the greatest impact is from the supply chain –materials, manufacturing,and distribution.

The impact of traditional stainless steel equipment comes almost entirely from its use –particularly the large amount of cleaning and sterilization required.

On average, single-use technologies had lower overall environmental impacts compared to traditional for all environmental impact categories in the study.

Location matters for climate change impact

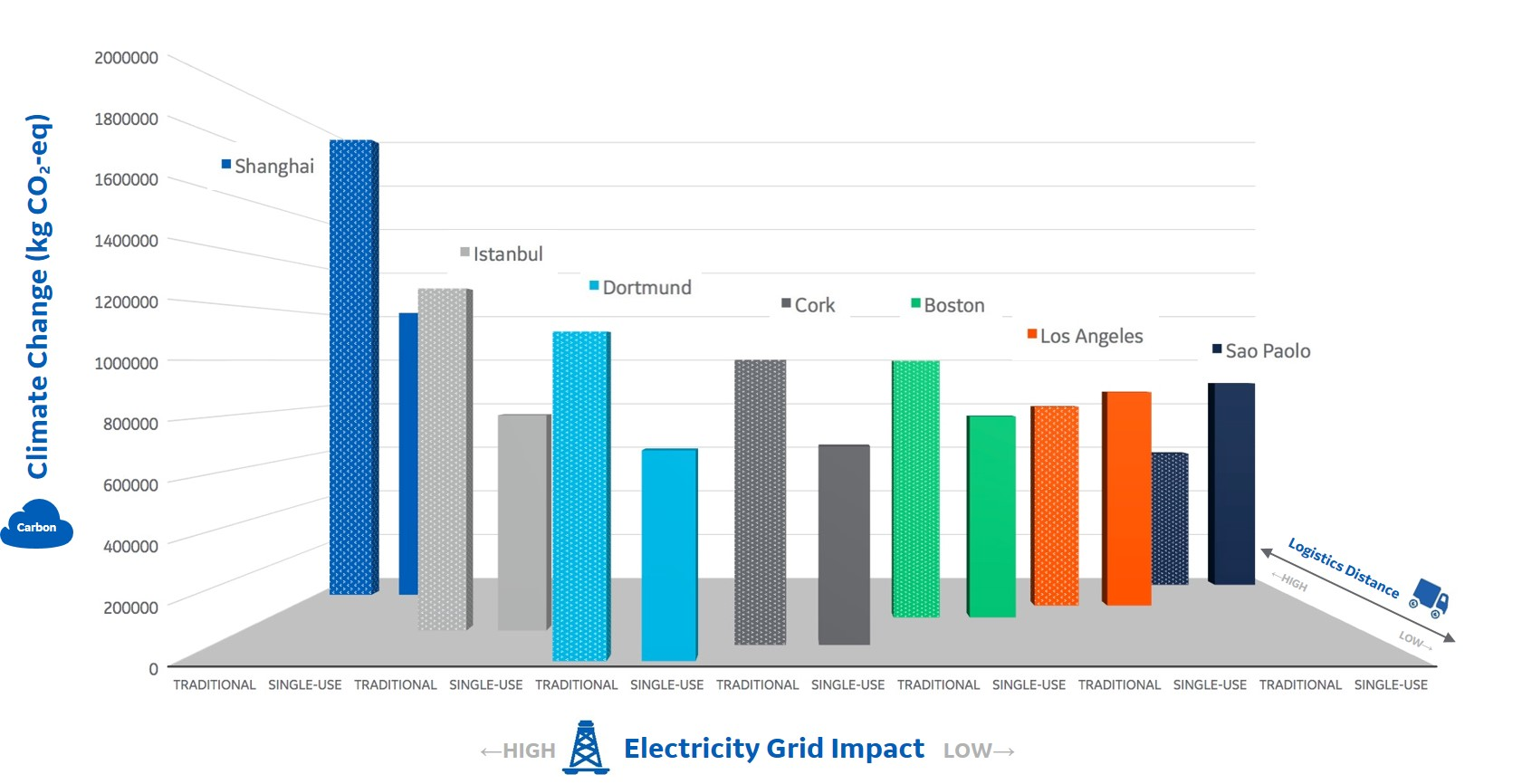

Location-specific data showed (Fig 2):

- The high energy demand of traditional equipment has more impact if the local grid is fossil fuel-powered, and less if there is more use of renewables.

- The supply chain impact of single-use equipment depends on logistics distance to the facility.

- In some cases, a hybrid system combining both types of equipment will be the most sustainable option.

Traditional equipment has high water use

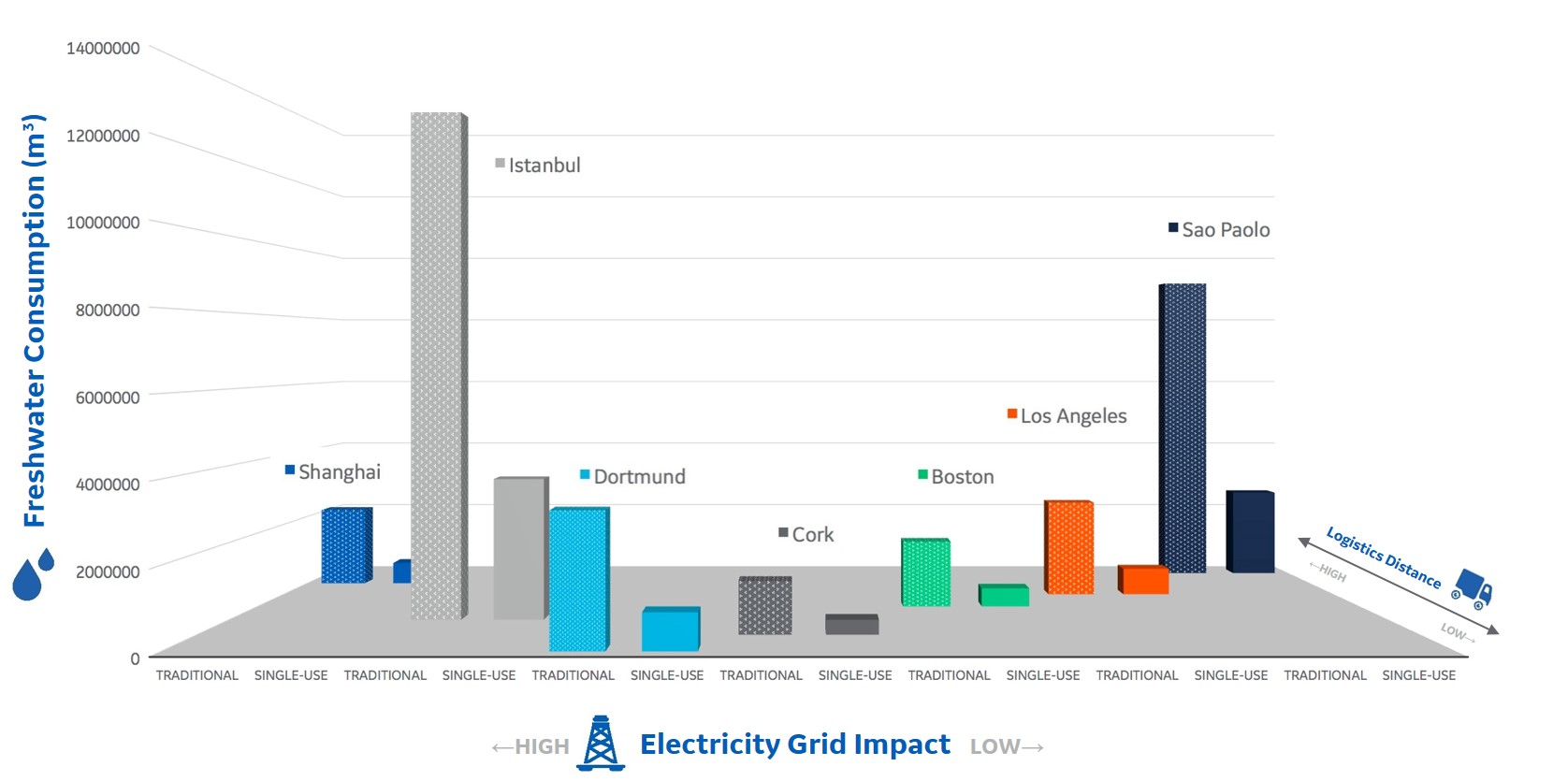

Although traditional equipment can have a lower carbon footprint in a few locations, the results for water use are consistent across locations. In every case, single-use systems used far less water than their stainless steel counterparts (Fig 3).

Fig 3. Comparison of freshwater consumption impact between traditional and single-use mAb bioprocess (2 ×2000 L)in different locations. Each location is represented by a unique color, with traditional process on left and single-use process on right. Impact (y-axis) is ranked by logistics distance (x-axis) and electricity grid impact (z-axis).

Download more detailed data

- Download the white paper: Single-use technology and sustainability: quantifying the environmental impact in biologic manufacturing

- Watch a webinar: Single-use technology and sustainability -quantifying the environmental impact

Key take-home messages

Using single-use technologies results in reduced environmental impact of mAb production… usually. Region of choice for a facility can strongly influence environmental impact due to transport and grid differences. Single-use disposal at end-of-life does not contribute significantly to environmental impact.

Choosing the best options for you

When you make the shift to single-use products, you want to maximize the benefits to the environment. That means considering a wide range of factors, from your specific production processes to the location of your facilities. Our experts can help you to put together a single-use system, or a hybrid of single use technologies and traditional equipment, designed to give you the fast, efficient production you need at a lower environmental impact.