Why automate cell therapy systems?

Today’s cell therapy treatments are often made at a small-scale, include manual preparation, and are usually produced for use in a clinical trial. Researchers spend days processing cellular material, monitoring its growth during the expansion phase, and preparing it for re-administration to the patient. With autologous treatments, this process must be completed for every patient to create their unique living drug.

In return, cell therapy offers life-changing outcomes. For example, terminal acute lymphoblastic leukemia patients achieved complete remission in 90% of cases during one cell therapy trial (1). But what if it were possible to get those results on a much broader scale? Automation may hold the key to making this happen.

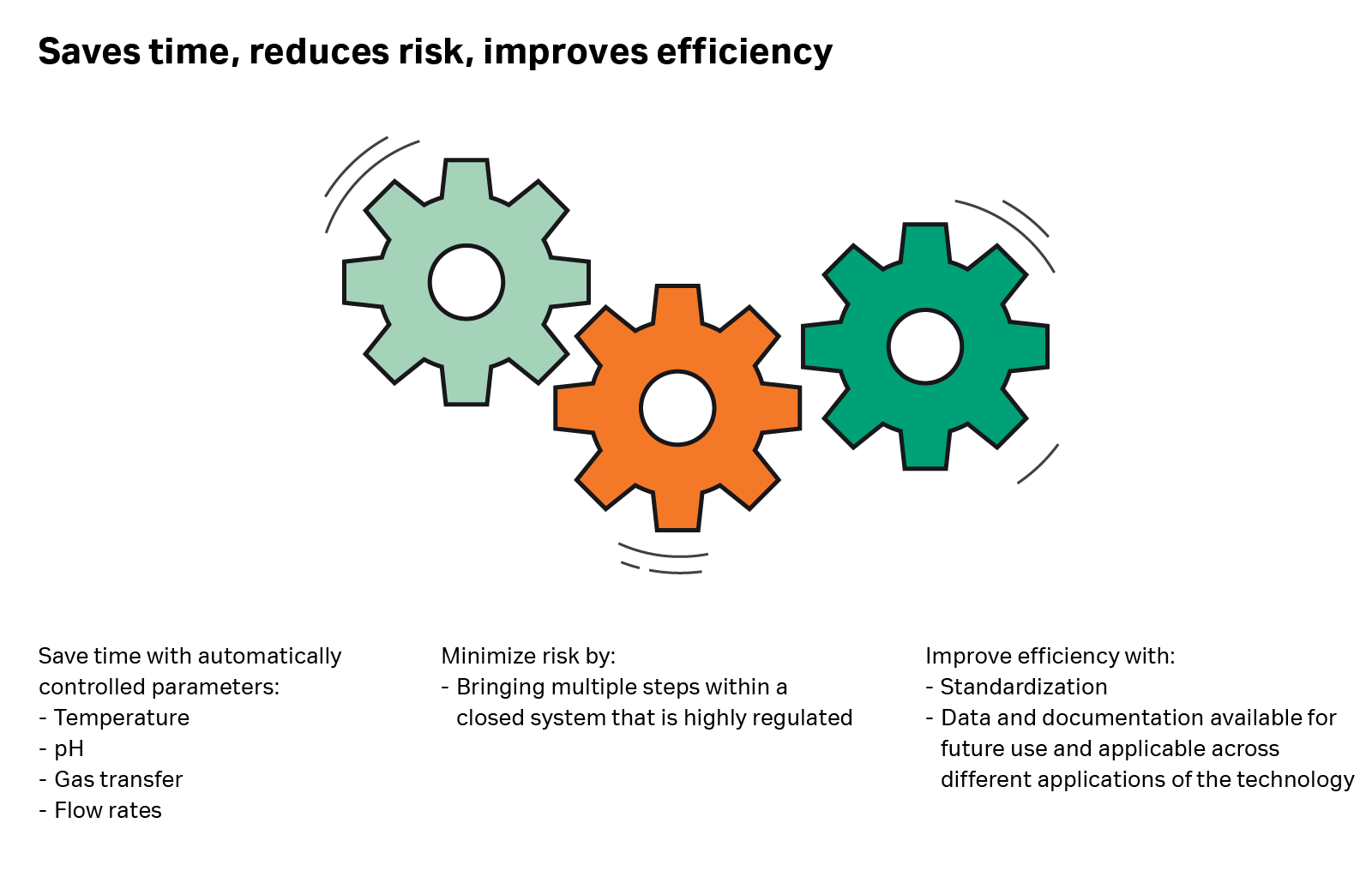

In short, for cell therapy manufacturers, automation can allow for consistency in scaling, save time, lessen the risk of manual input, and improve efficiency of operations.

Cell therapy enters mainstream medicine

The remarkable results emerging from cell therapy clinical trials suggest we are entering a new phase of medical treatment – one where we can expect far more from our healthcare interventions than we ever imagined. A generation ago, the outlook for cancer patients was bleak. Today, a far more positive prognosis is likely.

But to get these powerful treatments to those who need them, we need a manufacturing infrastructure that can generate cell therapies to meet the demand expected in coming years.

A modular approach to automation

Automation removes the risk of error, variation, and contamination associated with manual processing and is crucial for the reproducible manufacture of cell therapies approved for use in patient care. A modular approach will increasingly enable individual steps to be linked together and provides the flexibility needed to produce therapeutics in a standardized end-to-end closed system capable of scale out and scale up to meet the growing demand for high-quality biologics.

Saves time

Manual approaches to cell therapy production are time-consuming and tasks such as checking cells at regular intervals during expansion are laborious. The workflow and cleaning routines involved in maintaining the lab environment at a safe level is another time-draining factor.

Automated solutions such as the Xuri™ Cell Expansion System W25 reduce or remove many of these demands. After setting up a process, an operator can leave it running and turn their attention to other things while critical parameters such as temperature, pH, gas transfer, and flow rates are monitored and controlled automatically.

Reduces risk

Manual cell processing solutions tend to be complex with many steps, checks, and adjustments involved across isolation, expansion, harvesting, and preservation stages. Each one of these introduces potential for risk. A high level of expertise is required but material could still be inadvertently contaminated during any of the numerous open steps while limited process control can lead to difficulties in achieving high reproducibility.

An automated modular solution minimizes these risks by bringing multiple steps within a closed system that is highly regulated and controlled. Sefia™ and Sepax™ Cell Processing Systems and Xuri™ Cell Expansion System are functionally closed and maintain a consistent, replicable set of conditions that can be optimized for each cell therapy manufacturing application.

Improves efficiency

When a process is made up of multiple manual routines, changing it requires adjustments that need to be checked and documented. And where a customized process is used; documentation and protocols are of limited use because they will only apply to that setup.

A standardization approach means that what is learned in one project can be drawn on in future work, with data and documentation applicable across different applications of the technology. A modular chain of connected systems allows for process variation with different instruments running in customized configurations. Additionally, control of an individual instrument is straightforward to implement using built-in software and sensors. For example, the high-volume Sefia™ Cell Processing System offers up to eight fluid pathways, allowing plenty of scope for process design and adaptation.

For more details on a closed and semi-automated CAR T cell manufacturing workflow that can be adapted for cGMP compliance in commercial production, check out our application note.

References:

- Maude, S. L., Frey, N., Shaw, P. A., et al. (2014). Chimeric antigen receptor T cells for sustained remissions in leukemia. New England Journal of Medicine. 2014; 371(16): 1507-1517.