Column protection is key

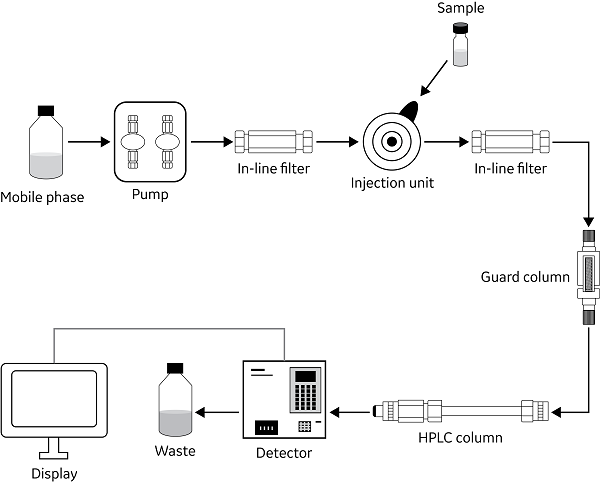

Use of high-performance liquid chromatography (HPLC) to characterize samples is an invaluable technique across numerous industries including the testing of pharmaceuticals, food, and environmental samples among others.

Because HPLC columns are central — and costly — equipment in many laboratories, protecting them from damage is a prime consideration to extend column life and protect your investment. A well-maintained column also produces consistent and accurate data, supporting confident analyses.

Improve column performance

Column performance depends on several factors, including sample properties, presence of insoluble particles, and cleaning and maintenance procedures.

It is not always feasible to work with the most favorable conditions for an increased column lifetime. For example, some samples have harsh but necessary pH conditions. However, appropriate column protection techniques and preventative maintenance procedures can help to maximize the life of a column and maintain HPLC efficiency.

What factors affect column lifetime?

Commonly reported HPLC problems include increased column back pressure, leakages and loss of pressure, and the inability to maintain a consistent flow rate. Either of these observations could indicate that a column’s performance is being compromised.

Particulates from unfiltered samples or mobile phases can contribute to these issues. Essentially, anything that enters the HPLC system runs the risk of introducing particulate matter onto the column matrix, potentially shortening the useful column lifetime.

Several other factors can cause damage to the bonded phase in a column, reducing its efficacy. These factors include reactive material in samples, harsh pH conditions, and excessive pressure. Chemical incompatibility between sample solvent and sample preparation consumables can also be damaging.

How can I protect the integrity of my results?

1. Sample preparation

Prefiltering or centrifuging samples prior to injection onto the column can help limit the addition of particulates to the system, helping to extend the lifetime of both the injector, guard column and the final column. A syringe filter or syringeless filter vial is suitable for this step, depending on the sample type, number of samples, and sample injection method.

Chemical-based sample pre-treatment is another way to protect column performance. Many different techniques are possible. The potential issue here is expense and time, calling for an appropriate balance between additional pre-treatment costs and their possible cost-saving benefits.

2. Mobile phase

The mobile phase also influences column performance.

Filtering and degassing the mobile phase will remove particulates and dissolved gas, ensuring they do not reach and damage the column. Filtration is especially important if the mobile phase contains buffer salts or modifiers from dissolved solid material. Additionally, adding this step to routine work can help reduce baseline noise in the chromatogram.

Also, consider the compatibility of your sample with the mobile phase, because some sample components are reactive with particular HPLC solvents. For example, aldehydes and ketones react with an amino mobile phase. Avoiding reactive combinations helps to protect columns against damage.

3. In-line filters and guard columns

In-line filters and guard columns help prevent particulates entering the system and the column, which is a critical component in HPLC system. The use of these column protectors depends on the application, with either one, or both, required.

A guard column is a short column that the sample and mobile phase pass through before entering the main column, helping to remove the impurities and suspended solids, preventing them from reaching the analytical column. The use of a guard column depends on the specific application because it can be an expensive protection option, requiring consideration of the costs against benefits. The guard column should be changed regularly, for example when there are changes in chromatographic behaviour such as backpressure, changes in retention time, or peak broadening.

4. Maintenance

Maintaining a clean column is also critical to extending column lifetime. Occasionally flushing the column with mobile phases that differ from those used on the system (e.g., more water or organics) can help clean the column. Extensive flushing in a backwards direction can also help with cleaning, especially if you notice increasing column back pressure.

Storing columns in an appropriate solvent can help prolong their life. Always consult the column’s handling instructions to identify the best storage solvent for that particular column.

Try the Whatman™ Filter Selector App to find out if you are using the most appropriate filtration solution for your samples. To discuss any challenges you are facing, please contact Cytiva's Scientific Support.

For samples or to contact a specialist

Related Products