What are track-etched membranes and why should you use them

Track-etched membranes (TEMs) are used to separate particles from solutions. Unlike traditional membranes, the holes of a TEM are all the same size. You can imagine a kitchen colander shrunk down until the holes are micron or even submicron size. Because the holes in a TEM are uniform, these membranes are often called true-pore membranes.

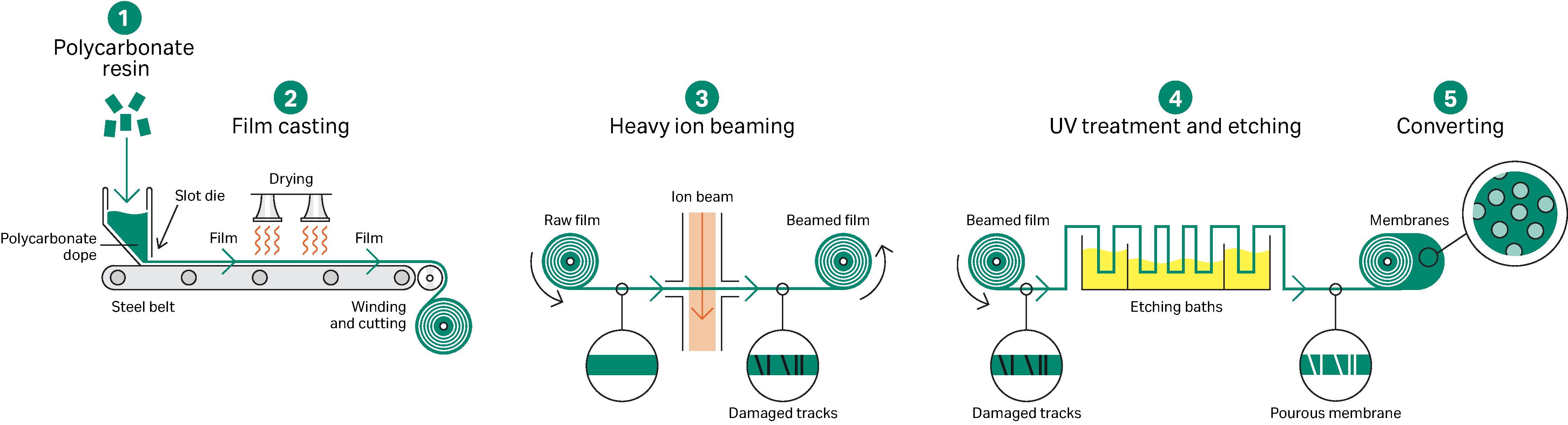

Track-etching technology uses a multistep process (Fig 1). First, polycarbonate or polyethylene terephthalate (PET) film is damaged by passing it through an ionized beam. In this case, damage is a good thing because the ions, which travel in a straight line through the film, weakens the film creating tracks that can be followed. Next, after a resting stage that follows the beaming process, the film undergoes a UV curing step to make the film more receptive to the etching process. Then, the film with the tracks is dipped into an acidic bath that eats away, or etches, the film following the tracks. During the etching process, each track becomes a pore of a very precise and equivalent size. Finally, the membrane is converted to its final format: slit reels, sheets, or any other configuration.

Fig 1. How track-etched membranes are made

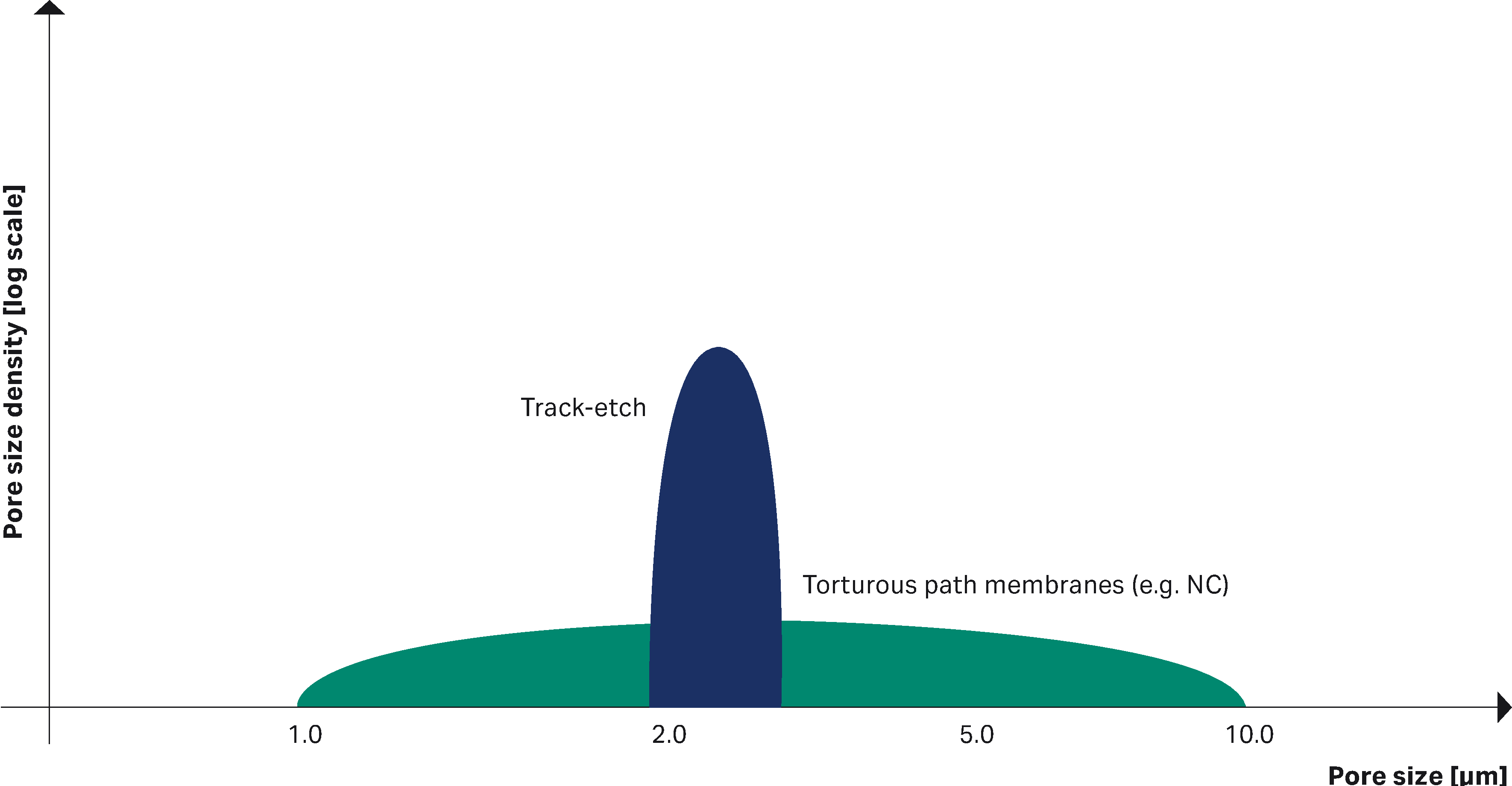

What’s special about the pores produced in this method is that they have a very narrow size distribution. The size distribution of the pores in other membranes (sometimes called tortuous-path membranes) is a wide and flat curve, whereas the size distribution of the pores in TEMs forms a sharp peak (Fig 2). What’s also special is that the pore diameter can be controlled so you can order a membrane that has pores that are the right size to capture a specific target while letting smaller contaminants filter through. You can also order membranes with a specific pore density to get the flow rate that you need.

Fig 2. A comparison of the size distribution of pores in a tortuous-path membrane (green) and in a track-etched membrane (blue).

Applications of track-etched membranes

The unique structure of TEMs makes them useful in a wide variety of applications because they very accurately size-select for a target. For example, suppose you are developing a vaccine and need to purify your product. You would first pass the solution through a TEM with pores just bigger than your vaccine molecule to remove any contaminants that are larger than your target molecule. Then you would pass the filtrate through a TEM with pores just smaller than your target to remove contaminants that are smaller. You’re then left with highly purified vaccine molecules sitting on the second TEM that can be resuspended and prepared for use.

Track-etched membranes are used for surface filtration. That means that the objects that you are capturing, which are larger than the pores in the membrane, end up sitting on top of the membrane. This property is useful for testing samples such as water or food and beverage. Bacteria can be isolated from a water or beverage sample using a TEM and then stained directly on the membrane for observation.

Track-etched membranes and diagnostics

Track-etched membranes could be the next big thing in diagnostics—particularly for point of care (POC) use. One of the goals in diagnostics is to get accurate results. You get more accurate results by having cleaner samples. And that’s where TEMs come in. They can be used to filter samples to isolate a target. The TEM makes the samples more uniform, so you get a better result.

The membrane works very well as a prefilter for a diagnostic test because it allows the sample to be cleaned by the TEM before the purified sample is released into the detection step of the assay for analysis. As such, a TEM can be added to a lateral-flow test for POC or direct patient use to prefilter a sample before it is deposited on the sample pad.

TEMs can be incorporated into different kinds of POC diagnostic tests. You could design a system in which a person loads a sample that goes through TEMs and comes out ready for PCR. Or better yet, have an automated system that does the PCR as well. This system could be standardized to allow you to create many different assays on the same automated system that can be used to diagnose different diseases.

Incorporating TEMs into POC diagnostic assays can increase the speed and efficiency of the tests. You can quickly take a fresh sample and purify it with very little loss of the target molecule. TEMs will also reduce the amount of training needed for the people who are handling samples. Using the membranes can be almost as simple as a lateral-flow test making them ideal for use in doctors’ offices or hospitals.

Your source for track-etched membranes

At this point, you might be wondering how to get TEMs. Afterall, target molecules of interest come in a wide range of sizes. You may not be able to buy off the shelf to get the pore diameter and pore density that you need. That’s where Cytiva can help. We have a range of different offerings but can also customize track-etched membranes to fit your needs. Or if you’d rather use ready-made polycarbonate track-etch membranes but need guidance on choosing and/or using them, you can talk to a team member for advice.

Request a sample