Capto™ hydrophobic interaction chromatography (HIC) resins are designed for high-throughput capture, intermediate purification and polishing steps of a wide range of biomolecules in bioprocess applications. These resins are based on high-flow agarose and offer excellent resolution in bioprocessing.

You can pack Capto™ HIC in AxiChrom™ columns to allow high flow velocities and high bed heights and increase the productivity and flexibility in your process design. To achieve effective purification, you need to be sure that the resin is efficiently packed. Poorly packed columns can lead to costly disruptions and loss of your valuable product. Robust and verified packing and testing methods can eliminate such concerns and risks.

This article explains best practices to help you efficiently pack Capto™ Phenyl (High Sub), Capto™ Butyl, Capto™ Octyl, Capto™ Phenyl ImpRes, and Capto™ Butyl ImpRes chromatography resins in our AxiChrom™ chromatography columns.

Example results are shown in the accordions at the bottom of this page.

Capto™ chromatography resin characteristics

Capto™ chromatography resins are based on highly rigid agarose that allow high flow velocities, which is essential for raising productivity in large-scale operations. These resins offer you a wide range of bed heights and flow velocities. Capto™ resins are divided into two groups depending on average bead size.

Capto™ Phenyl (High Sub), Capto™ Butyl, and Capto™ Octyl have an average bead size of 75 μm and are used for capture and intermediate purification steps. The pressure-flow specification in large columns is 600 cm/h at less than 0.3 MPa (3 bar, 43.5 psi) and at a 20 cm bed height (tested with water at 20°C in a 1 m diameter column).

Capto™ Phenyl ImpRes and Capto™ Butyl ImpRes resins have an average bead size of 40 μm giving you high resolution in your bioprocessing. The pressure-flow specification for Capto™ ImpRes in large columns is 220 cm/h at less than 0.3 MPa (3 bar, 43.5 psi) at a 20 cm bed height (tested with water at 20°C in a 1 m diameter column).

General packing considerations

Definitions

The height of a gravity-settled bed differs from the height of a bed settled under low flow (consolidated) due to the properties and the behaviour of the resin under different conditions. Therefore, you should separate the compression factor (CF) from the packing factor (PF). For example, in water in AxiChrom™ 50, when consolidated at 60 cm/h, the PF is 1.18 and the CF is 1.10 for Capto™ Butyl ImpRes.

Equations to calculate CF, PF, and column volume (CV) are shown below:

Compression factor, CF = Lsettled / Lpacked

Packing factor, PF = Lcons / Lpacked

where

Lsettled = bed height measured after settling by gravity

Lcons = consolidated bed height, that is, bed height measured after settling the resin at a given flow velocity

Lpacked = packed bed height

CV = Lpacked × AC

where

AC = cross-sectional area of the column

When packing AxiChrom™ columns, PF is used in the packing procedure to calculate the final packed bed height after the consolidation step. CF is used in the chromatography resin preparation step to calculate the resin volume needed to pack a desired bed height.

Properties of Capto™ HIC resins in various packing solutions

Capto™ HIC resins settle quickly in water, in 20% ethanol, and in salt solutions for packing. When you use these solutions, remember to rinse tubing and nozzles directly after packing to prevent clogging of the flow path.

Adding salt to packing solutions slows the settling of the resin beads and allows them to settle less tightly. Therefore, it is very difficult to measure slurry concentration by gravity with salt-based solutions. However, the slurry concentration method described below allows for quick and accurate determination of slurry concentration.

For example, when Capto™ HIC ImpRes resins are settled at 60 cm/h, the consolidated bed height will be up to 7% higher in salt solution and sodium hydroxide (NaOH) solution and up to 4% in 20% ethanol compared to in water. The effect can be compensated for by using different PF. However, for optimal performance of the packed bed, we recommend specific packing solutions for different column types and sizes, which is further described in this article.

Slurry preparation

Capto™ HIC resins are supplied in 20% ethanol. Before packing, transfer the resin to the packing solution as described in the instructions for the column that you intend to pack.

Preparing the resin to form a slurry can be performed manually by shaking/stirring or using a mixer such as Media Wand™ slurry mixing and transfer tool. Shaking gives good results but is often not practical for larger volumes. When stirring, it is preferable to use soft stirrers without sharp edges. Media Wand™ suspends the resin directly in the container and transfers the slurry to BioProcess™ Resin Mixer in one operation, which makes it suitable for large-scale packing.

To achieve the correct amount of chromatography resin for packing to target bed height or compression, it is important that you measure slurry concentration correctly. When you prepare the slurry, start by calculating the chromatography resin volume (V) needed to pack the desired bed height. You can determine the slurry concentration in several ways, but to get an accurate slurry concentration of Capto™ resins, we recommend the Slurry Concentration Kit, which contains all the materials required for determination of slurry concentration.

PACKING CAPTO™ HIC RESINS IN AXICHROM™ COLUMNS

These columns are low-pressure, axial mechanical compression chromatography columns designed for process development and biopharmaceutical manufacturing. Mechanical axial compression enables accurate and reproducible control of the packing, even with large diameter columns. The columns are available in many different configurations and materials (see the data file for more details).

The columns are scalable and will give you predictable results by enabling a uniform plug flow through the bed, irrespective of column size. The columns feature Intelligent Packing with pre-programmed methods that support all column sizes.

Intelligent Packing makes column operation straightforward and gives you very high packing success rates. The packing methods we describe here apply to bed heights of up to 40 cm depending on column diameter.

When packing AxiChrom™ 50 to 200 columns for use with ÄKTA™ chromatography systems, Intelligent Packing control is managed by UNICORN™ control software. For AxiChrom™ 300 to 1600 columns, Intelligent Packing is performed by AxiChrom™ Master, a separate unit that comprises a touchscreen operated user interface, or from UNICORN™ control software on ÄKTA process™ chromatography system.

Intelligent Packing in AxiChrom™ columns – general considerations

Packing methods are created by entering values for the packing variables in the Intelligent Packing wizard, for example, resin, slurry concentration, and target bed height.

Contact your Cytiva representative for more information about automated AxiChrom™ functionality.

Specific considerations for packing Capto™ HIC resin in AxiChrom™ columns

A general bed height interval for Capto™ HIC resin in AxiChrom™ columns is 10 to 40 cm. Packing variables and recommended packing buffers are given in Table 2 and Table 3.

Using ÄKTAprocess™ for packing and unpacking Capto™ HIC

When you pack Capto™ HIC resin in AxiChrom™ 300 to 1000 columns via ÄKTAprocess™ chromatography system, the UNICORN™ Intelligent Packing wizard custom resin option is used. When you apply this option, you will need to manually input additional packing variables as PF and adapter velocity.

Table 2. Packing variables for packing Capto™ Phenyl HS, Capto™ Butyl and Capto™ Octyl in AxiChrom™ columns

| Packing variable | AxiChrom™ 50 | AxiChrom™ 100 | AxiChrom™ 200 | AxiChrom™ 300 to 1600 |

| Resins | All Capto™ resins | Capto™ Phenyl HS, Capto™ Butyl | ||

| Packing solution | 0.4 M NaCl in 20% EtOH | Water | Water | |

| Packing speed/velocity | 60 cm/h | 60 cm/h | ||

| Packing factor | 1.18 | 1.15 | 1.13/1.16* | |

*When packing AxiChrom™ 1200 to 1600, PF shall be 0.03 higher (1.16).

Table 3. Packing variables for packing Capto™ HIC ImpRes resins in AxiChrom™ columns

| Packing variable | AxiChrom™ 50 to 200 | AxiChrom™ 300 to 1000 |

| Packing solution | 0.4 M NaCl in 20% EtOH | Water |

| Packing speed/velocity | 30 cm/h | 60 cm/h |

| Packing factor | 1.20 | 1.15 |

| Flow conditioning | Optional for AxiChrom™ 50 at 10 cm bed height: 270 cm/h for 30 min* | None |

*Flow conditioning is done at this rate with the packing solution, if another buffer is used, adjust velocity for viscosity of the solution.

TESTING THE PERFORMANCE OF THE PACKED COLUMN AND COLUMN RESULT EXAMPLES

Process-scale packed columns must perform with a high degree of efficiency over many processing cycles (that is, display very high stability). The efficiency of a packed column can be expressed in terms of height equivalent to a theoretical plate (HETP) and asymmetry factor (AS). This test should be repeated regularly to monitor the state of the packed bed throughout the working life of the column. If the test results are to be comparable over time, conditions such as flow velocity (cm/h), liquid pathway, sample composition, and elution buffer should be kept constant.

Set the requirements of the test in accordance with the test conditions and the goal of the purification. This is further described in our article on column efficiency testing. To compare the performance of columns packed with chromatography resins of different particle diameters, the reduced plate height (h = HETP/average bead diameter [dp]) is typically used. As a guideline, a value of h < 3 is very good at optimal test conditions.

Test conditions used in this study

In this study, optimal test conditions for each column setup is described.

Capto™ Phenyl HS, Capto™ Butyl, Capto™ Octyl

Sample: 2% v/v acetone for columns packed with water

0.8 M NaCl for AxiChrom™ 50 column

2% acetone in 0.4 M NaCl in 20% EtOH for AxiChrom™ 100 column

Sample volume: 1% of the column volume (CV)

Test flow velocity: 30 cm/h

Eluent: Water

0.4 M NaCl for AxiChrom™ 50 column

0.4 M NaCl in 20% EtOH for AxiChrom™ 100 column

Capto™ HIC ImpRes

Sample: 2% v/v acetone for columns packed with water

2% acetone in 0.4 M NaCl in 20% EtOH for AxiChrom™ 50, 100, and 200 columns

Sample volume: 1% of the column volume (CV)

Test flow velocity: 30 cm/h

Eluent: Water

0.4 M NaCl in 20% EtOH for AxiChrom™ 50, 100, and 200 columns

RESULTS IN AXICHROM™ COLUMNS

The columns packed with the methods outlined above were tested for plate number, asymmetry, pressure-flow velocity, and stability.

Examples of efficiency range and stability results for Capto™ Phenyl (High Sub), Capto™ Butyl, and Capto™ Octyl resins packed in AxiChrom™ 50, 100, and 200 columns can be seen in Table 4. Results for packing in AxiChrom™ 300, 600, 1000 and 1600 columns are shown in Table 5.

Examples of efficiency range and stability results for Capto™ Phenyl ImpRes and Capto™ Butyl ImpRes resin packed in AxiChrom™ 50, 100, and 200 columns can be seen in Table 6. Results for packing in AxiChrom™ 300 and 600 columns are shown in Table 7.

Table 4. Results for Capto™ Phenyl HS, Capto™ Butyl, and Capto™ Octyl resins packed on AxiChrom™ 50, 100, and 200 columns

| Column | Bed height (cm) | Capto™ resin | Average N/m* | Reduced plate height (h) range * | Asymmetry factor (As) range* | Flow velocity for stability test (cm/h)† | Change after stability test (%)† | |

| h | As | |||||||

| AxiChrom™ 50 | 10 | Phenyl | 6800 | 1.9 to 2.1 | 1.1 to 1.3 | 1320 | 5 | 8 |

| 20 | Phenyl | 7100 | 1.8 to 2.2 | 1.1 to 1.2 | 660 | -2 | 2 | |

| 20 | Butyl | 8300 | 1.5 to 1.7 | 1.1 to 1.2 | 660 | 10; 0‡ | 18; 3‡ | |

| 20 | Octyl | 8400 | 1.5 to 1.7 | 1.0 to 1.1 | 660 | -1; 4‡ | 9; -3‡ | |

| 40 | Phenyl | 7300 | 1.7 to 2.0 | 0.9 to 1.0 | 330 | -4; 2‡ | 14; 4‡ | |

| AxiChrom™ 100 | 20 | Phenyl | 8400 | 1.5 to 1.9 | 1.1 to 1.2 | 660 | 5 | 7 |

| 20 | Butyl | 7600 | 1.7 to 1.8 | 1.1 to 1.2 | 660 | -2 | 7 | |

| 20 | Octyl | 7300 | 1.8 to 1.9 | 1.1 to 1.2 | 660 | -2 | -9 | |

| AxiChrom™ 200 | 10 | Phenyl | 9100 | 1.4 to 1.5 | 1.1 to 1.2 | 1320 | 3 | 1 |

| 20 | Phenyl | 9700 | 1.3 to 1.4 | 1.1 | 660 | 8 | 4 | |

| 40 | Phenyl | 9200 | 1.4 to 1.6 | 1.0 to 1.1 | 330 | 1 | 4 | |

* Test performed at optimal test conditions. Average and ranges of upflow and downflow tests for at least three packs.

† Stability tests were run once for each bed height/resin/column combination in water for 16 h at given velocity.

‡ Data from two consecutive stability tests

Table 5. Results for Capto™ Phenyl HS and Capto™ Butyl resins packed on AxiChrom™ 300, 600, 1000, and 1600 columns

| Column | Bed height (cm) | Capto™ Resin | Average N/m* | Reduced plate height (h) range * | Asymmetry factor (As) range* | Flow velocity for stability test (cm/h)† | Change after stability test (%)† | |

| h | As | |||||||

| AxiChrom™ 300 | 20 | Phenyl** | 8700 | 15 to 1.6 | 1.2 to 1.3 | 660 | 5 | 7 |

| 20 | Butyl | 9400 | 1.4 to 1.5 | 1.1 to 1.2 | 660 | 2 | 7 | |

| 40 | Phenyl | 8500 | 1.6 | 1.1 | 330 | 4 | 5 | |

| AxiChrom™ 600 | 20 | Phenyl | 8200 | 1.5 to 1.7 | 1.1 to 1.3 | 660 | -2 | -1 |

| 30 | Phenyl | 8700 | 1.5 to 1.6 | 1.1 to 1.3 | 440 | 0 | 4 | |

| AxiChrom™ 1000 | 20 | Phenyl | 9300 | 1.4 to 1.6 | 1.1 to 1.2 | 660 | 2 | -4 |

| AxiChrom™ 1600 | 15 | Phenyl | 8600 | 1.4 to 1.6 | 1.2 to 1.3 | 920*** | -5 | -2 |

* Test performed at optimal test conditions. Average and ranges of upflow and downflow tests for at least three packs.

** Only two packing tests were performed.

*** Max flow rate with available equipment

† Stability tests were run once for each bed height/resin/column combination in water for 16 h at given velocity.

Table 6. Average values from at least three packings for Capto™ HIC ImpRes resins on AxiChrom™ 50, 100, and 200 columns

| Column | Bed height (cm) | Capto™ ImpRes resin | Average N/m* | Reduced plate height (h) range * | Asymmetry factor (As) range* | Flow velocity for stability test (cm/h)† | Change after stability test (%)† | |

| h | As | |||||||

| AxiChrom™ 50 | 10 | Phenyl | 11000 | 2.0 to 2.1 | 1.3 to 1.4 | 480 | -1** | 1** |

| 20 | Phenyl | 12500 | 1.6 to 1.9 | 1.1 to 1.3 | 240 | 4; 1‡ | 11; 0‡ | |

| 20 | Butyl | 12800 | 1.7 to 1.9 | 1.1 to 1.3 | 240 | 3: 2‡ | 11: 4‡ | |

| 30 | Phenyl | 10500 | 2.1 to 2.2 | 1.1 to 1.1 | 170 | -6 | 7 | |

| AxiChrom™ 100 | 20 | Phenyl | 13700 | 1.5 to 1.9 | 1.1 to 1.3 | 240 | -2 | 8 |

| 20 | Butyl | 13800 | 1.5 to 1.7 | 1.2 to 1.2 | 240 | 7; 0‡ | 10; 2‡ | |

| AxiChrom™ 200 | 10 | Phenyl | 14200 | 1.5 to 1.6 | 1.2 to 1.3 | 480 | -4 | 2 |

| 20 | Phenyl | 13200 | 1.5 to 1.8 | 1.2 to 1.4 | 240 | 2; -5‡ | -7; -2‡ | |

| 30 | Phenyl | 13900 | 1.6 to 1.6 | 1.1 to 1.2 | 170 | 1; 0‡ | -14; -1‡ | |

* Test performed at optimal test conditions. Average and ranges of upflow and downflow tests for at least three packs.

**post flow conditioning

† Stability tests were run once for each bed height/resin/column combination in water for 16 h at given velocity.

‡ Data from two consecutive stability tests

Table 7. Results for Capto™ HIC ImpRes resin packed in AxiChrom™ 300 and 600 columns

| Column | Bed height (cm) | Capto™ ImpRes resin | Average N/m* | Reduced plate height (h) range * | Asymmetry factor (As) range* | Flow velocity for stability test (cm/h)† | Change after stability test (%)† | |

| h | As | |||||||

| AxiChrom™ 300 | 20 | Phenyl | 14900 | 1.6 to 1.7 | 1.1 to 1.3 | 240 | -7 | 5 |

| 20 | Butyl | 14800 | 1.6 to 2.0 | 1.1 to 1.4 | 240 | -1 | 6 | |

| AxiChrom™ 600 | 20 | Phenyl | 16800 | 1.3 to 1.4 | 1.0 to 1.3 | 240 | 2 | 3 |

* Test performed at optimal test conditions. Average and ranges of upflow and downflow tests for at least three packs.

† Stability tests were run once for each bed height/resin/column combination in water for 16 h at given velocity.

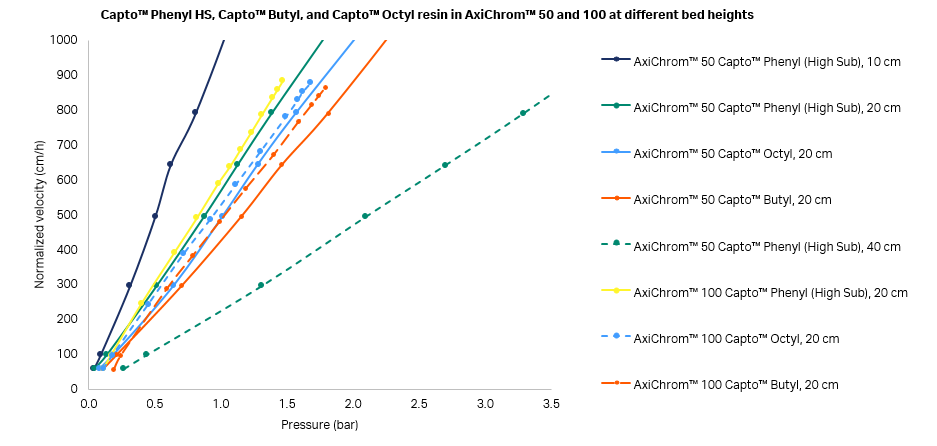

Fig 1. Pressure flow curves for Capto™ Phenyl HS, Capto™ Butyl, and Capto™ Octyl in AxiChrom™ 50 and 100 at different bed heights. 1 bar = 0.1 MPa = 14.5 psi.

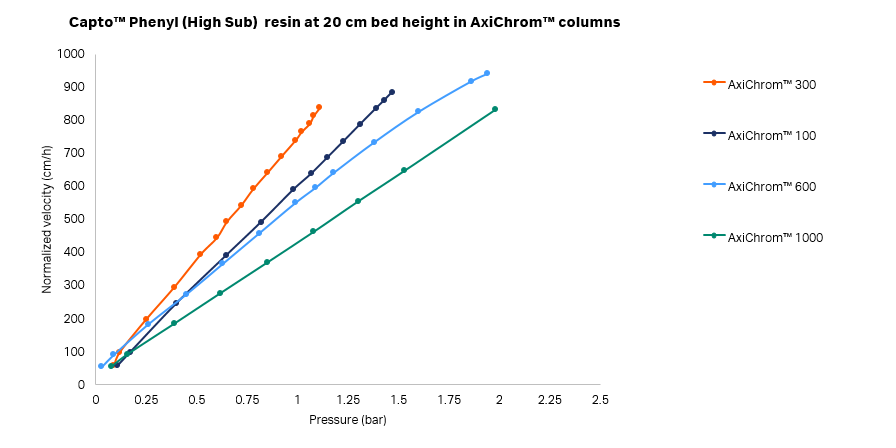

Fig 2. Pressure flow curves for Capto™ Phenyl HS at 20 cm bed height in different AxiChrom™ columns. 1 bar = 0.1 MPa = 14.5 psi.

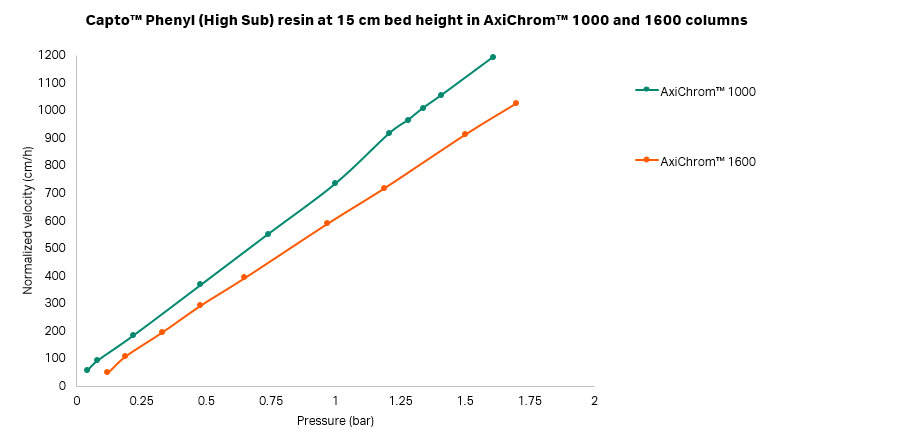

Fig 3. Pressure flow curves for Capto™ Phenyl HS at 15 cm in AxiChrom™ 1000 and 1600. 1 bar = 0.1 MPa = 14.5 psi.

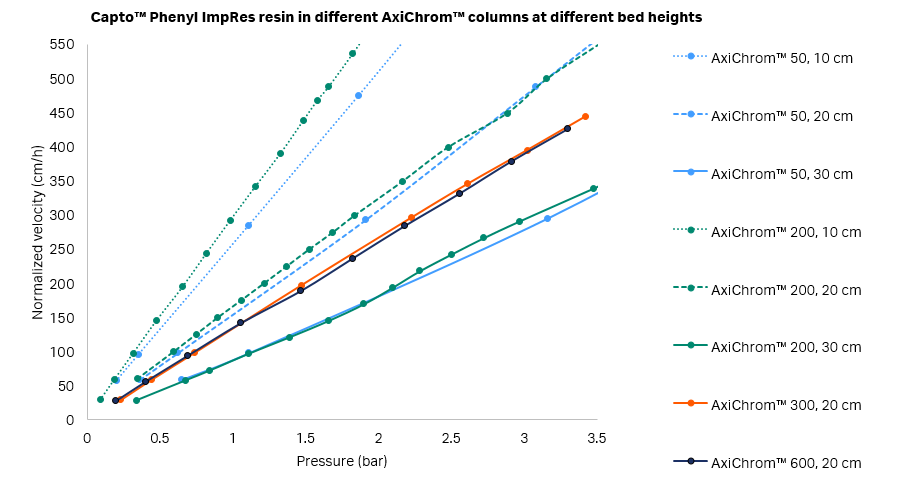

Fig 4. Pressure flow curves for Capto™ Phenyl ImpRes in different AxiChrom™ columns at different bed heights. 1 bar = 0.1 MPa = 14.5 psi.

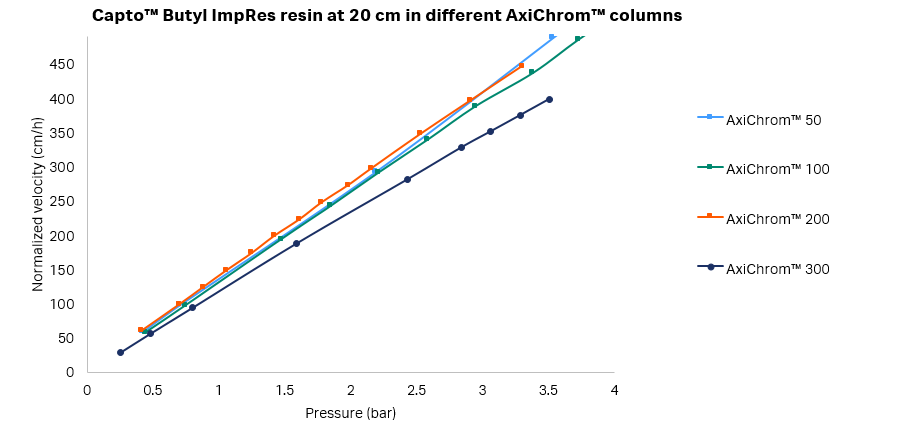

Fig 5. Pressure flow curves for Capto™ Butyl ImpRes at 20 cm in different AxiChrom™ columns. 1 bar = 0.1 MPa = 14.5 psi.

Conclusions

To utilize the full flow potential of the Capto™ HIC resin, we recommend using AxiChrom™ in your process. The flexibility of column diameters and bed heights gives you full utilization of Capto™ HIC resin flow capacity, allowing for processes with increased bed heights if your floor space is limited or at lower bed heights and larger diameters to decrease process time. We have described packing Capto™ HIC resins in AxiChrom™ columns using the custom mode feature of Intelligent Packing. We have also described each packing method in relation to a specific packing solution. Deviation from use of the packing solutions described may have significant impact on the PF and subsequently on the packing result. The packing result and bed performance are well withing normal acceptance criteria for a well packed bed and ensure robust and stable process performance.

Related links

- AxiChrom™ 300 to 1600 columns

- AxiChrom™ 50 to 200 columns

- HIC resins

- HIC prepacked columns

- Overview of Cytiva resins

- HIC resource center

CY30548-25Oct22-AN