Continuous chromatography

Continuous chromatography is emerging as an opportunity for process intensification, thanks to the efficiency and economical operation it allows.

The ÄKTA pcc 75 chromatography system is a predefined custom product designed for continuous downstream processing of proteins. It is specialized for periodic counter-current chromatography (PCC), a process setup that allows improved speed and more complete use of a chromatography column’s binding capacity.

How does PCC work?

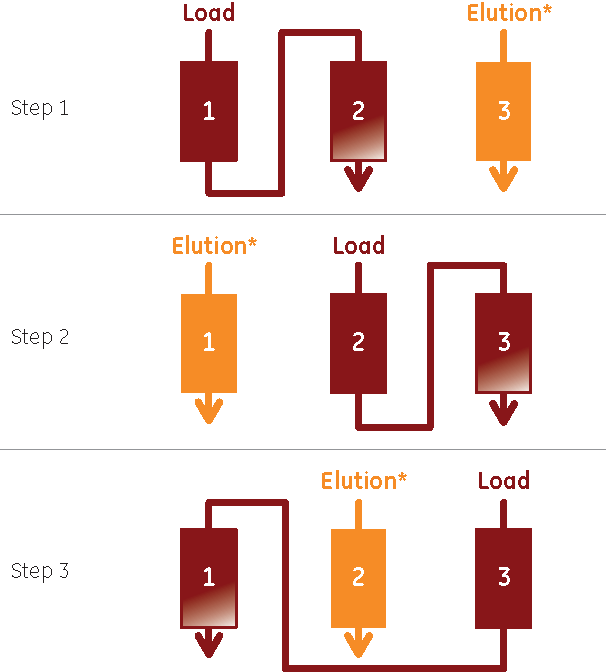

Three or more columns are switched between loading and non-loading zones in a turn-taking, cyclical manner, so that loading is continually taking place. When a loading column reaches a pre-defined level of breakthrough, it is disconnected and the load is redirected to the next column. The disconnected column can be washed, eluted, and regenerated while loading continues uninterrupted in the other columns (Fig 1).

PCC increases the use of a chromatography resin’s capacity, allowing higher levels of loading compared to traditional batch chromatography, where safety factors limit the sample load below breakthrough. In PCC, the breakthrough of product is caught by the second column in the loading zone, so that more of the resin’s capacity can be used and product is not lost.

Fig 1. The principle of 3C PCC. Step 1: column 1 and 2 are loaded with sample (red). Step 2: column 1 has reached the defined level of breakthrough (BT) and is disconnected from the loading zone to be eluted, while column 2 becomes the first column in the loading zone. Step 3: column 2 has reached the defined BT level and column 3 becomes the first column in the loading zone. This procedure is repeated in a cyclic manner to achieve a continuous operation. *Elution phase in this figure includes wash, elution, strip, CIP, and re-equilibration.

Changing conditions, dynamic control

The ÄKTA pcc 75 offers both static and dynamic control functionality. Dynamic control helps ensure consistent results even when there are changes to the column resins or product stream during the purification process. The technology is based on UV multi-sensor analysis of the product stream, and supports the US FDA’s process analytical technology initiative (PAT).

How dynamic control works

Two UV signals are used to pinpoint saturation levels at the point of breakthrough. One is sampled before the column and one after. A 100% breakthrough level is defined as ∆UVmax. By comparing the baseline (precolumn) UV signal to the post-column one, it’s possible to see what the degree of breakthrough is as a proportion of ∆UVmax, and how much it deviates from the target level.

The UV sensor readings allow the operator to monitor column saturation levels and adjust for variations in resin binding capacity or changes to the composition of the feed batch, so that the desired degree of breakthrough can be kept constant. The UV detection is sensitive enough to pick up fine variation in the product stream, for example in perfusion cell culture.

The ÄKTA pcc 75 can also be run with static control, with predefined automatic column switch times implemented by the UNICORN software.

Application results

To demonstrate the usefulness of dynamic control in PCC, we set up a three-column process in an ÄKTA pcc 75 system, using a cell culture feed containing mAbs. Both chromatography resin capacity and feed concentration were deliberately changed in different studies to test the system’s capabilities.

We used stepwise and gradual changes in mAb feed concentration to test the dynamic control system’s ability to compensate for major and subtle changes. For chromatography resin variation, we used one HiScreen MabSelect SuRe column and two HiScreen MabSelect SuRe LX columns. The MabSelect SuRe LX columns have higher capacity.

As the process was carried out, the system was able to compensate for concentration changes, maintaining a consistent breakthrough level with both gradual and sudden concentration changes. In the second study it also adapted to changes to the chromatography resin’s performance, halting the loading process when the breakthrough level became too high. It also produced a lower elution volume from the lower-capacity MabSelect SuRe column, indicating that it had recognized and adjusted for its lower dynamic binding capacity.

Read the full paper - The use of dynamic control in periodic counter-current chromatography

Interested in ÄKTA pcc 75?

The ÄKTA pcc 75 is a custom system available for direct sale. To find out more and discuss your needs with one of our representatives, contact us.

Related information