Water Quality Testing Procedure: Explained

Water quality is monitored continuously and there are many variants of testing procedures to determine water quality. One common water quality testing procedure in the filtration industry and domestic sector is suspended solids testing. Suspended solids testing is carried out in specialized laboratories where tests on water samples ranging from drinking water to effluent (wastewater originating either from industrial plants or from domestic sewage) is analysed. An important part of this process is using sample filtration to remove insoluble particles from liquid samples and retains particles for suspended solids analysis.

What Does TDS Stand For?

TDS stands for Total Dissolved Solids and it refers to the molecules and ions that remain in a water sample after filtration. This measurement consists mainly of minerals and other ions, which do not generally present a health risk. However, dissolved ions do affect the flavor of water, which is why TDS testing is important in drinking water testing and it will also determine the water quality.

What Does TSS Stand For?

TSS is the total suspended solids (TSS) that are present in a water sample and measurement of TSS, unlike TDS, is commonplace in effluent testing, such as in the testing of liquid waste or sewage that has been discharged into a river or the sea. Gravimetric assessment is perhaps the most common method of determining the TSS.

How to Test For Total Suspended Solids in Water?

In Europe, EN 872 describes a standard method for suspended solids measurement in water. It specifies the equipment and materials that are suitable for determining TSS. Method 2540D, which has been approved by the United States Environmental Protection Agency (EPA), is the standard method employed in the US. It is from the publication “Standard Methods for the Examination of Water and Wastewater.”

Although most countries have their own testing standard, it is likely based off one of these two methods. For example, the British standard BS EN 872:2005 is derived from EN 872.

Water Quality Testing Parameters: How to Measure Water Quality

There are many parameters that are tested to indicate the water quality depending on the various purposes for measuring the quality of the water and the nature of the sample, such as through chemical indicators or biological indicators. This is therefore going to be different for different companies. However, a key indicator is the concentration and composition of particulate matter in a sample. There are different ways to measure contaminants in water, but it’s common for many labs to follow predefined methods or standards.

One standard, and one of the simplest parameters to determine water quality, is total solids (TS). TS is the total weight of all dissolved and non-dissolved content that is present in the water and is what would determine the water quality. This means that to measure the water quality, you would have to add the total dissolved solids (TDS) and total suspended solids (TSS) together.

Water Purification: Filtration

When determining the workflow of water quality test, the choice of filter is critical to compliance with standard methods and plays a major role. Complying with existing standards for testing involves using filters with the required attributes. These specifications help to ensure that the Total Suspended Solids (TSS) water quality measurement will be valid.

EN 872 lists the following specifications for filters in determining TSS:

- Filter should be borosilicate glass fiber.

- Filter should not contain binders.

- Mass per unit area should be between 50 and 100 g/m2.

- Mass loss in a blank measurement should be less than 0.017 mg/cm2.

Water Quality Testing: GE Standards & Compliance

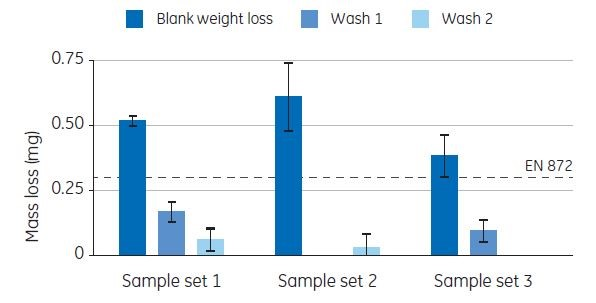

To assess compliance with the standards as defined in BS EN 872:2005, researchers tested GE’s Whatman GF/C filters for mass loss. The filters were found to be compliant following the initial washing step (Fig 1).

Fig 1. Mass loss of Whatman GF/C filters out of the box and after sequential washing according to BS EN 872:2005, n=10 per sample set.

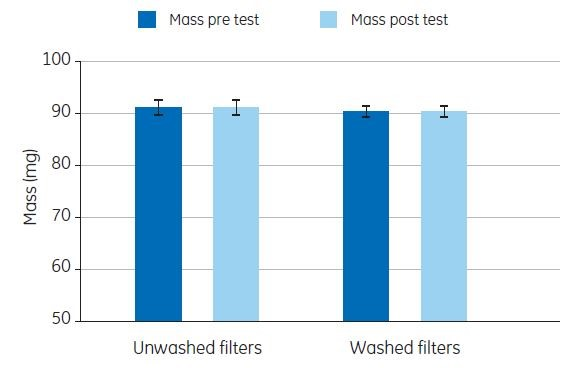

In another experiment, researchers measured the ability of GF/C filters to resist moisture absorption. This attribute is important, because water uptake affects the weight of a filter and influences measurements. The experimental results demonstrate that storage in a high-humidity environment does not affect the weight or the quality of the measurement (Fig 2).

Fig 2. Mass of Whatman GF/C filters before and after being stored at 75% relative humidity for 72 h.

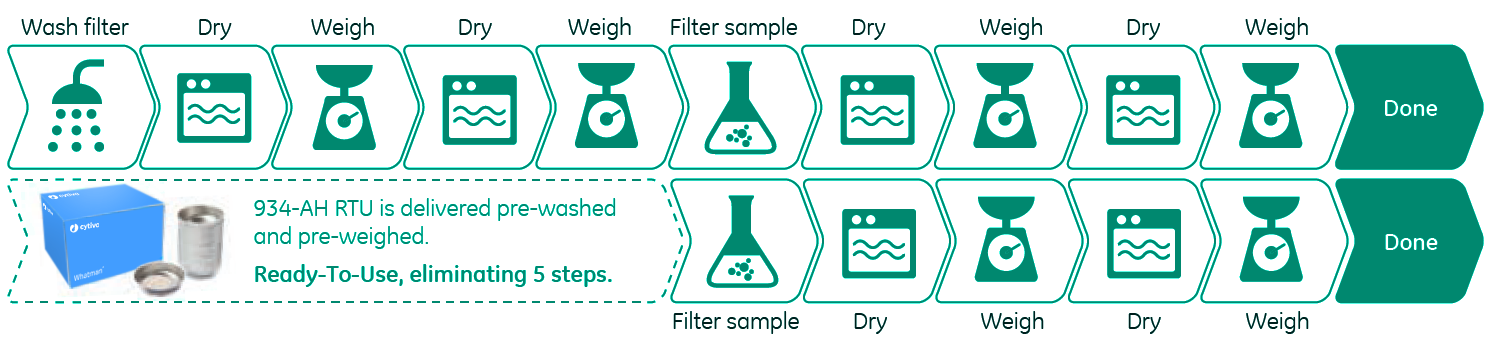

For the US standard, preweighed Whatman 934-AH RTU filters ensure full compliance with method 2540D. This method states that prior to use of a filter it must be washed 3 times, then dried and weighed until a constant weight is obtained. Using 934-AH RTU straight from the box also saves time by eliminating 5 steps from the filtration process compared to a traditional glass fiber filter (Fig 3).

Fig 3. Filtration steps in compliance with method 2540D of traditional glass fiber filters (top) vs. Whatman 934-AH RTU (bottom).

The results shown here can help in making informed decisions on filter selection, saving time and costs and providing confidence in water quality analyses.

Try our Whatman Filter Selector App to find out if you are using the most appropriate filtration solution for your samples. To discuss any challenges you are facing, please contact Cytiva Sciences Scientific Support.

Related Documents

- Environmental testing for water, air, and soil

- Quality Matters: Whatman filters for water monitoring

Related Products

- Whatman GD/X Syringe Filters

- Whatman Grade 934-AH RTU

- Whatman Grade GF/A Glass Microfiber Filters

Tools

- Whatman Filter Selector

- Lab filtration glossary