Developing Whatman™ ‘woven’ paper

Before the Whatman™ company became known for laboratory filtration, its founder invented the world’s finest writing paper.

In 1733, innovator James Whatman applied textile weaving techniques to papermaking. His new ‘woven’ paper was robust and smooth —ideal for fine art and quality printing. This paper was used by Thomas Gainsborough for watercolors, by John Baskerville for printing and, later, by Queen Victoria for letters.

Discovering a plasma substitute

The development of a plasma substitute for emergency blood transfusions saved lives and offered a new way to manage injury and trauma.

It was 1941 when researcher Björn Ingelman wondered why his sugar beet juice had become gooey. He traced the cause to dextran, a polysaccharide produced from sucrose by bacteria. Perhaps this sticky substance could replace plasma in blood transfusions? His curiosity led to Pharmacia’s Macrodex™ dextran solution.

Pioneering paper chromatography

Scientists used Whatman™ filter paper to detect different substances within a mixture, launching paper chromatography as a technique for clinical research and development.

In 1944, researchers Consden, Gordon, and Martin used strips of Whatman™ brand filter paper to conduct early paper chromatography experiments. These studies aimed to determine the number of amino acids in proteins and complemented the parallel work that later earned Martin and Synge a Nobel Prize.

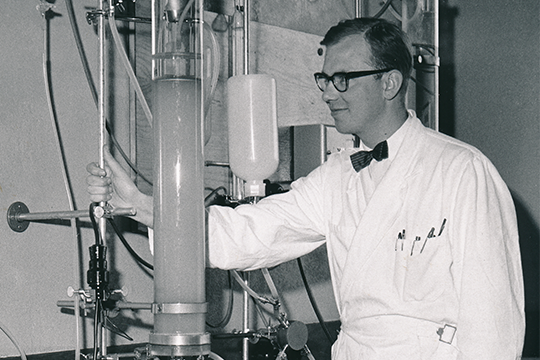

Inventing gel filtration

The development of gel filtration allowed for the separation of biomolecules by size, also known as size exclusion chromatography.

At Uppsala University in Sweden, scientists Jerker Porath and Per Flodin discovered — as a result of a ‘failed’ experiment — that columns packed with cross-linked dextran gel separated proteins. Flodin and Porath published this finding and brought it to Pharmacia. The company introduced Sephadex™ dextran gel, the first gel filtration resin, in 1959.

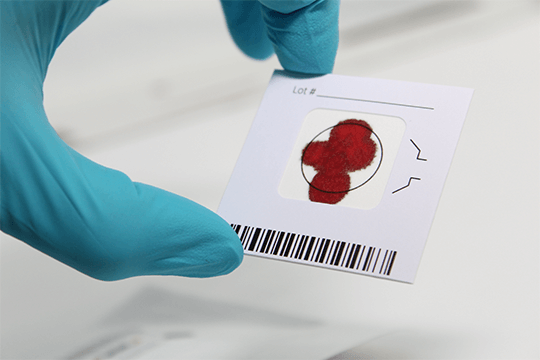

Improving cell serum

Innovations that led to the development of the first high-quality serum have made modern cell culture processes possible.

When Dr. Rex Spendlove couldn't get the high-quality serum he needed to study a deadly viral disease affecting children in developing countries, he developed his own. His efforts led to the creation of HyClone™ serum, which paved the way for the collection, filtration, and processing techniques used in cell culture manufacturing today.

Delivering insulin to all who need it

The use of chromatography columns to purify insulin allowed this critical hormone to be manufactured at scale, making widespread treatment available for people with diabetes.

In 1968, Pharmacia used large chromatography columns — previously for filtering milk in dairy production — to purify insulin from the pancreases of cows and pigs. At last, enough of this lifesaving therapy could be processed at scale for the treatment of diabetes everywhere.

Harnessing SPR technology

The development of SPR technology allowed researchers to study interacting molecules in real time — and non-invasively and label-free — leading to the development of new, better drugs.

Surface plasmon resonance (SPR) technology was used for the first real-time biomolecular interaction analysis of a biological system in 1983. SPR technology ultimately led to the invention of Biacore™ systems. Today, the Biacore™ instrument continues to offer advanced optical biosensing, with real-time, label-free, and noninvasive analyses.

Upgrading purification tech

Innovations in protein purification technology provided scientists with a much-needed upgrade to fast protein liquid chromatography (FPLC) processing.

In 1996, scientists developed a way to perform all liquid chromatographic techniques on a single, flexible platform. This new technology led to the development of ÄKTA™ instruments and was celebrated for being versatile, modular, and reliable. Today, Cytiva is recognized as a world leader in delivering preparative protein purification solutions to the life sciences community.

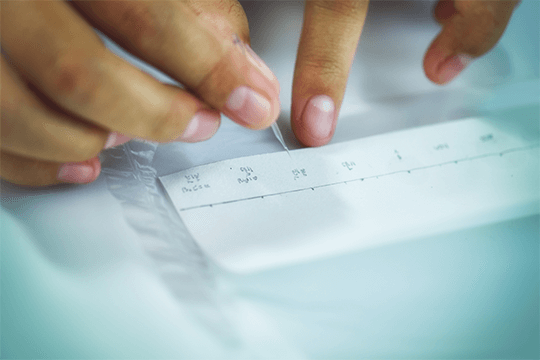

Pioneering FTA paper

The development of FTA technology let scientists collect, transport, store, and purify DNA, with no freezer required.

In 1999, by impregnating filter paper with a clever mix of chemicals, a new paper was invented that could preserve samples of genetic material. This unique system was able to lyse cells, prevent bacterial growth, and protect the DNA. At last, scientists could safely and easily collect, transport, store, and purify DNA at room temperature.

Booming antibodies

As the therapeutic use of antibodies gained rapid success, process development and production demands increased. Efficient and robust protein A chromatography remained the standard for monoclonal antibody purification, but new resin functionalities were needed.

In 2001, Cytiva introduced the first MabSelect™ resin to meet these increased demands. Based on a novel high-flow agarose matrix, this new resin allowed processing of more than 10 000 L of feed in one working day. After the launch of the first MabSelect™ product, we continued to develop additional MabSelect™ versions —all with further improvements to advance antibody research and production.

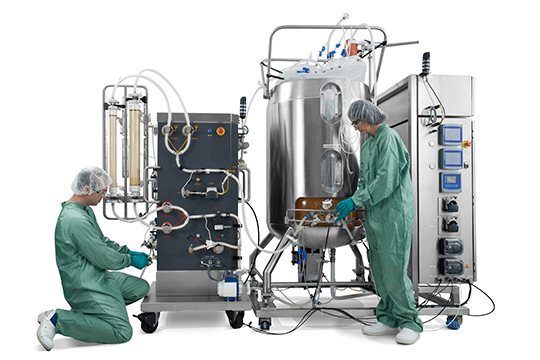

Inventing single-use bioreactors

A new biomanufacturing technology leapfrogged the inflexible 'clean-in-place, steam-in place' protocols of stainless-steel systems.

In 2002, after losing his job, Parrish Galliher followed his vision for a new paradigm in biomanufacturing. The resulting Xcellerex™ instruments revolutionized the protocols of stainless-steel biomanufacturing by offering a disposable platform that uses less hot water and is flexible and efficient.

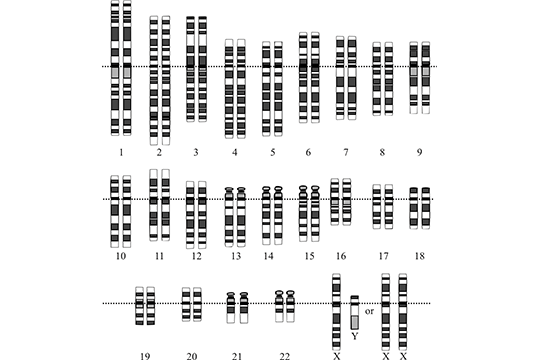

Mapping the human genome

Advancing DNA sequencing technologies was a major focus of the scientific community at the turn of the century, and remains an important area in research and clinical care.

Amersham Biosciences answered the call by developing an innovative, high-throughput sequencing technology. The MegaBACE™ platform was used for about 30% of the mapping done by the Human Genome Project, which ultimately succeeded in completely sequencing the human genome for the first time — a historic achievement which continues to lead to medical breakthroughs today.

Launching the first single-pass TFF system

The development of our innovative tangential flow filtration system helped optimize downstream purification steps for a range of biopharmaceutical processes and applications.

In a milestone moment for Pall Life Sciences, our Cadence™ system was the first to use direct flow-through concentration with no product recirculation. This technology allowed manufacturers to increase yields and throughput while achieving product recovery greater than 98% — all with a smaller footprint. Customers have gone on to use this system to produce a range of drugs and vaccines with greater efficiency.

Curing cancer with CAR-T

The move away from chemically synthesized drugs toward biologics and cell-based therapies is offering hope to patients fighting cancer, autoimmune diseases, diabetes, and more.

In 2012, Emily Whitehead was the first child to beat cancer with CAR-T cell therapy. Our researchers used bioreactors to grow engineered cells and identify the best conditions for each cell type. They also used laser-powered flow cytometers to study cell properties and robots to run production automation experiments.

Fostering new discoveries

We are working to improve the future of biological medicines through innovation and collaboration.

In 2018, Cytiva and the Swedish government co-founded Testa Center™, a global test bed tasked with finding new ways to support academia, the bioprocess industry, and start‑ups. At this innovation hub, researchers have access to the latest technologies, facilities, and resources to foster new ideas and technologies. It's a super-charged springboard to global collaboration and discovery.

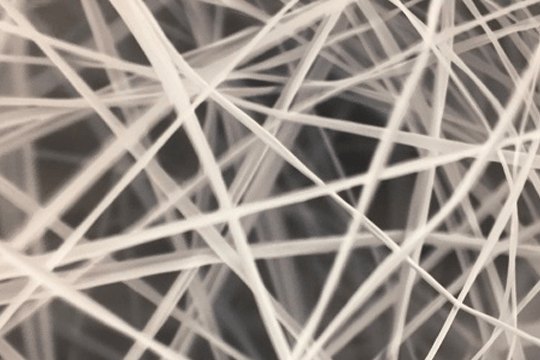

Launching Fibro technology

Therapeutic proteins remain a growing area of focus in medical research and clinical care. Effective and efficient purification processes are essential to getting these critical treatments to patients in need.

In 2020, Cytiva introduced the first Fibro chromatography products, based on electrospun cellulose fibers that enable both high flow rates and high binding capacity. Fibro technology offers flexible, high-productivity purification solutions from process development to manufacturing scale.

Racing to beat COVID-19

We joined the entire life sciences community in supporting widespread efforts to prevent and manage COVID-19.

In response to the COVID-19 pandemic, researchers have worked faster than ever to develop immunization and treatment options. Cytiva scientists were involved in 70% of the global efforts, including 380 vaccine development programs and 200 monoclonal antibody initiatives.

Cytiva scientists and researchers continue to foster our company's rich culture of exploration and discovery in the quest to transform human health.