The oligonucleotide therapeutics market is growing, and the pipeline is diverse. With more than 2000 oligo therapeutics in development and 20 commercialized oligonucleotide drugs on the market to date, the potential for these highly specific sequences is being realized and is set to continue. Building on 40 years of experience, Cytiva launched ӒKTA oligosynt™ benchtop oligo synthesizer in 2022. It is the newest member of our oligo synthesizer family; a family of systems capable of synthesizing at scales ranging from 10 µmol to 1800+ mmol.

We understand it is important for you to have the ability to optimize the synthesis parameters and conditions for every individual cycle. Only with rigorous process optimization can you achieve both the high quality and cost efficiency required to produce an oligonucleotide at scale.

We know that speed for successful process development and scale-up is correlated to having the expertise and experience at hand when optimizing your synthesis process as well as the right support for the full workflow process. When you purchase systems from Cytiva for your oligonucleotide workflow, you gain access to our network of oligonucleotide product specialists, scientists, and scientific support associates who can leverage their significant experience to fast-track your molecule’s development. In other words, we can provide optimization and scientific support for the whole oligonucleotide manufacturing workflow because all the system verification has already been done. Cytiva oligonucleotide synthesizers are tested and validated using our own workflow consumables in-house. This optimization can help you prepare for better performance and improved yields. Investing your time here and making the right selections and decisions can save you later.

All Cytiva synthesizers and columns are verified using our Primer Support™ 5G solid support. The columns are designed to hold the solid support so that none escapes into the flow path, which could lead to hardware issues and can potentially cause down-time.

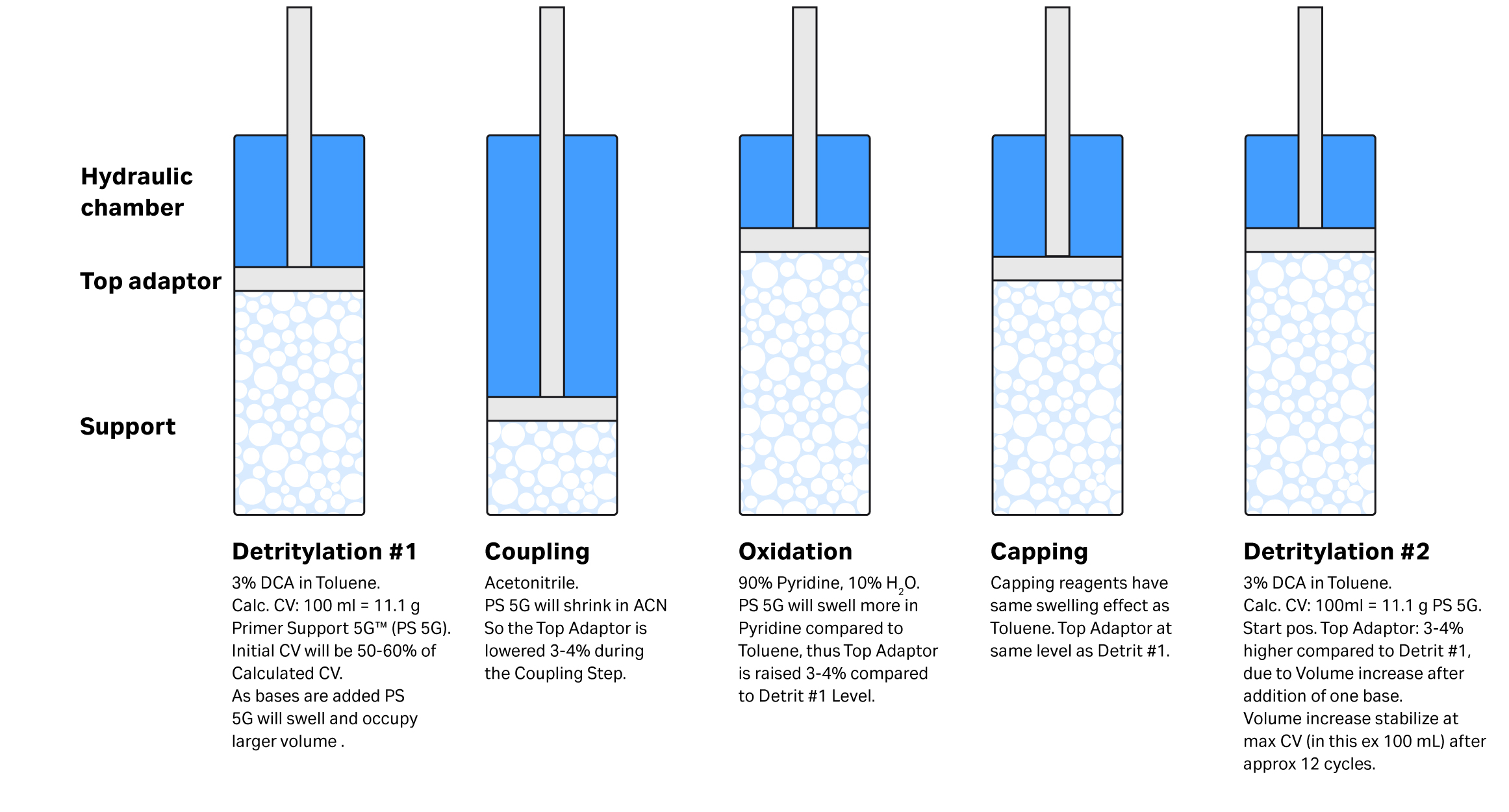

UNICORN™ software is preprogrammed with easy selection criteria with an option of a universal starting linker (UnyLinker) or a starting base to make method creation easier. Primer Support 5G solid support is a high-loaded, polystyrene bead with a swelling behavior typical for highly cross-linked solid supports. The swelling and shrinking behaviors are different depending on the reagent or solvent added in the different steps of a cycle.

Fig 1. Swelling and shrinking characteristics of Primer Support 5G solid support in each step is very predictable.

Using traditional columns with a fixated adaptor position, the column volume will remain the same throughout synthesis and will leave a headspace on top of the solid support bed. This headspace will lead to dilution of reagents entering the column before reaching the top of the bed as well as an overconsumption of washing solvent.

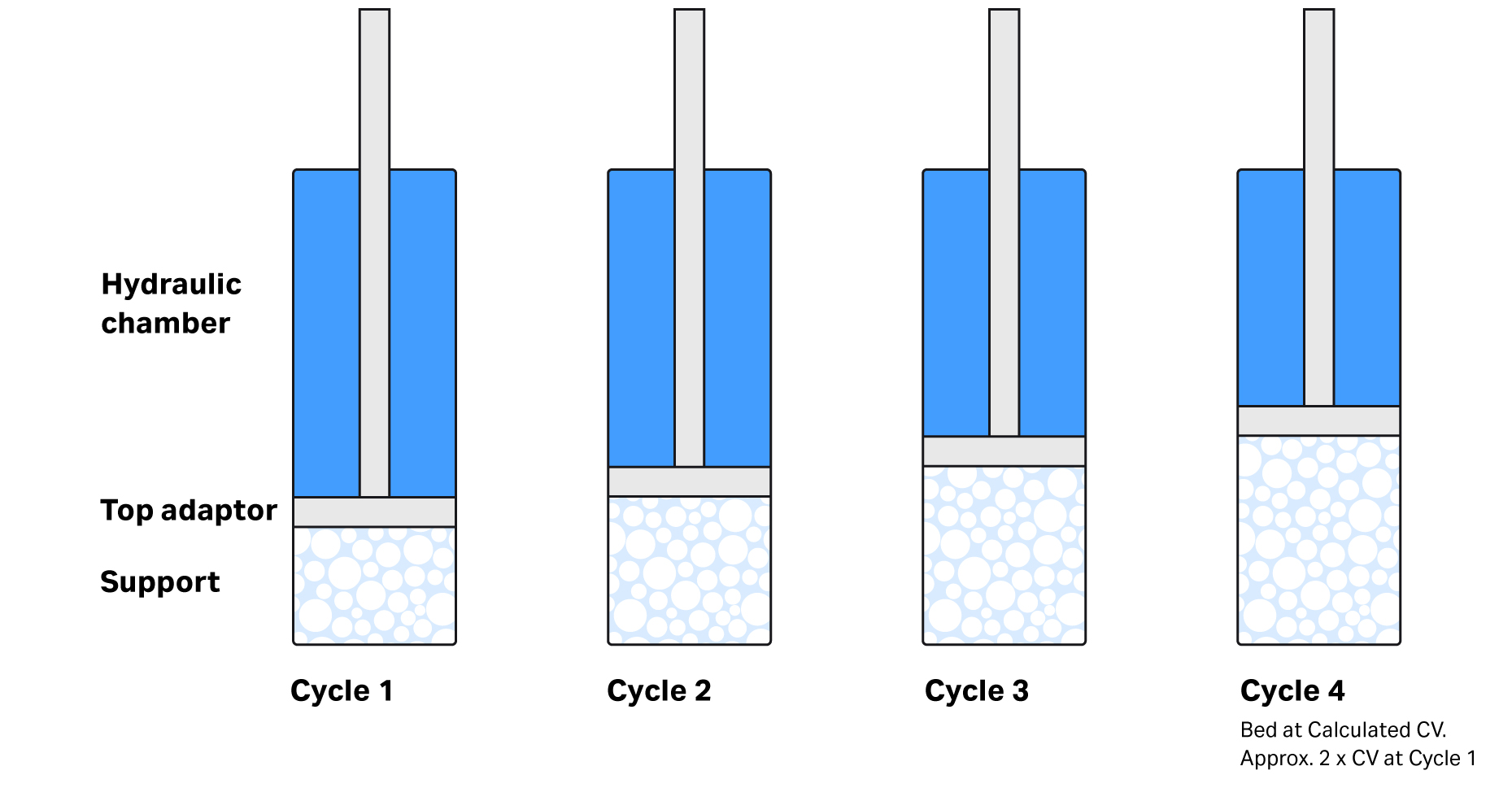

For the first 12 bases added to the growing sequence, the bed is also continuosly growing. This growing bed requires an adaption of the adaptor in the column to leave the bed with sufficient room while still optimizing the column volume.

Several columns offered by Cytiva optimize the column volume in each synthesis step and throughout synthesis when using Primer Support 5G solid support. The adjustment of the adaptor is fully automated and is expected to save solvent at all scales and maintain optimum synthesis conditions in the column volume.

Fig 2. The bed of Primer Support 5G solid support grows for each addition of base until 12th base is added, approximately.

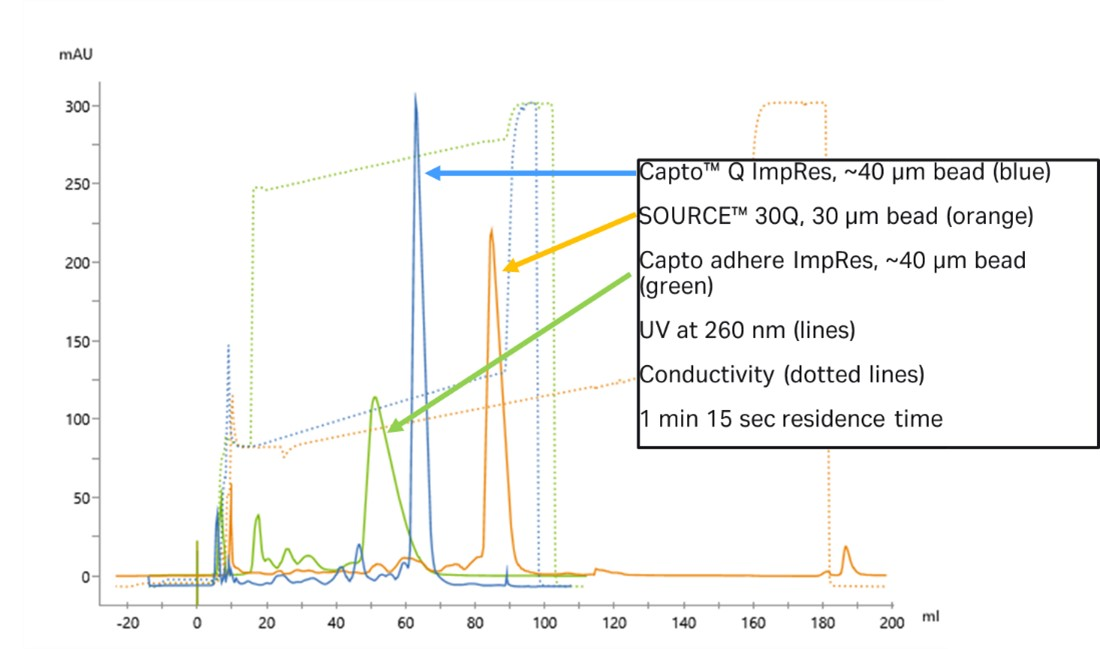

Our synthesis systems are designed and developed by the same engineers who built our huge expertise and reputation in purification in Sweden. With these decades of experience in purification, Cytiva is very well positioned to guide you through the whole oligonucleotide manufacturing workflow. The purification resins to use post-synthesis depends on whether the oligo has a dimethoxytrityl (DMT) protection group on or off. DMT on in the 5’ end provides hydrophobicity to the oligonucleotide. Thus, hydrophobic interaction chromatography (HIC) can be used; we use for example the HIC resins Capto™ Phenyl ImpRes resin or Capto Plasmidselect resin for this. For DMT off, the negative charge on the phosphate group is used for an ion exchange chromatography. The resin we recommend is Capto Q ImpRes, but Capto adhere ImpRes resin can be advantageous for some sequences (see example below). DMT on is recommended when you want to achieve very high purity without compromising too much on recovery. Purification based on the negative charge of oligonucleotides, without 5’-DMT group, is much easier overall and can be used to purify oligonucleotides in the 20 to 25mer range with up to > 90% purity and high recovery.

An example of purification of a DNA 21mer without the DMT protection group on can be seen in Figure 3. SOURCE™ 30Q resin and Capto Q ImpRes resin are strong anion-exchangers. Capto Q ImpRes resin has a generally higher capacity than SOURCE 30Q resin. Capto adhere ImpRes resin has a ligand that is multimodal (has both ion-exchange and hydrophobic functionality) and gives a different elution profile than the anion exchange resins. The elution profile can vary depending on the sequence composition.

Fig 3. An example of purification of a DNA 21mer without the DMT protection group on.

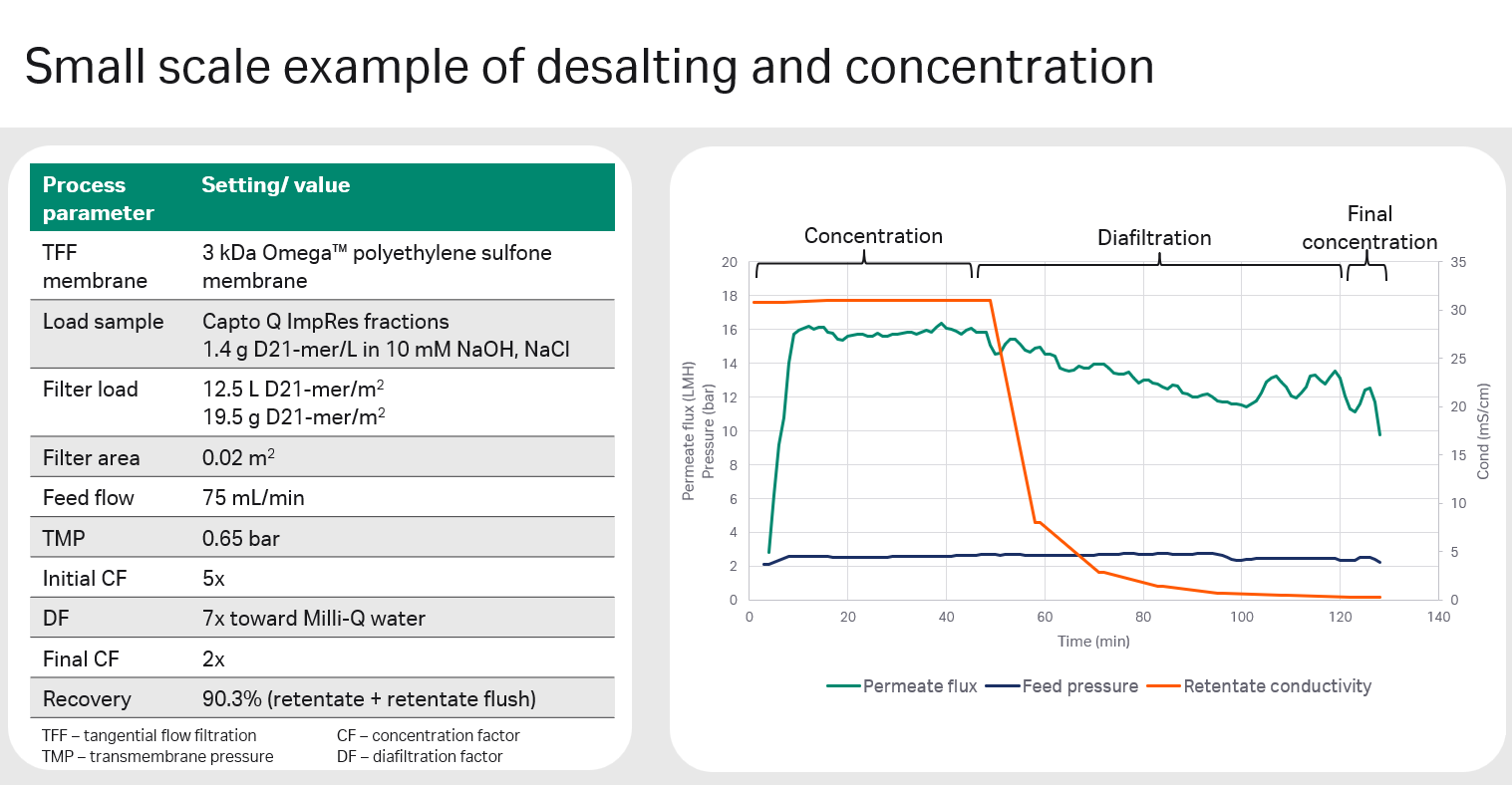

Purification of oligonucleotides includes a requirement for desalting after AIEX or HIC purification and optionally to condition the sample before loading the sample to chromatography columns. Size-exclusion chromatography (SEC) or tangential flow filtration (TFF) are options for conditioning and desalting. Filters newly added to our portfolio, including Omega™ polyethylene sulfone membrane and T-series cassette with Delta regenerated cellulose membrane enhance our oligonucleotide workflow offerings. Filters for oligonucleotides are complicated compared to protein filtration because oligonucleotide synthesis uses solvents such as acetonitrile, which can reside in the sample after cleavage from the solid support and deprotection. The solvent-compatible Delta regenerated cellulose filters are available down to a 10 kDa cut-off and are ideal for longer oligos. Omega filters (polyethylene sulfone, PES) can be used when solvent concentration is low, for example during desalting, and come down in size to 1 KDa. The 3 kDa cut-off version is suitable for oligos longer than 20 bases.

Fig 4.Represents the desalting and concentration of 21mer DNA oligonucleotide approximately 6 kDa in size. This procedure was carried out using an Omega polyethylene sulfone membrane with a 3 kDa cut-off. The sample that was desalted and concentrated was oligonucleotides in fractions collected after AIEX purification using Capto Q ImpRes chromatography resin.

In conclusion, Cytiva has four decades of extensive expertise and capacity in oligonucleotide research and development. This proficiency goes beyond synthesis alone. Our team of scientists and engineers has cultivated a robust understanding of purification and filtration methodologies applicable to a wide array of molecules. Consequently, Cytiva is poised to offer comprehensive optimization and scientific assistance across the entirety of the oligonucleotide workflow, backed by rigorous verification processes. Leverage our specialized knowledge to streamline your efforts to expedite the progression of your molecule to subsequent phases.