The ÄKTA process™ chromatography system is available in two standard configurations. The ÄKTA process™ CFG system is operated with UNICORN™ software, and the ÄKTA process™ DCS system is customized with a distributed control system.

ÄKTA process™ CFG system with UNICORN™ software is available in three flow rate ranges from 1 L/h to 2000 L/h, and with either electropolished stainless steel or polypropylene process piping. The integrated process picture allows real-time control and monitoring of runs and automated column packing is built-in. Configurable options include additional inlets, outlets, particle filters and column connections; the type and quantity of sensors; and isocratic versus gradient and inline dilution (ILD) functionality.

See how it compares

Built on decades of chromatography expertise, the ÄKTA process™ system delivers significant advancements over its predecessor. Explore key improvements in usability, automation, and scalability in the comparison chart.

Pack and run columns with confidence

ÄKTA process™ system is compatible with AxiChrom™ columns between 100 and 1600 mm inner diameter (i.d.), making it ideal for packing and running columns for a wide variety of projects. The integrated Intelligent Packing function and dual column valve make it quick and easy to get robust reliable columns ready for use. For AxiChrom™ columns 300 mm or larger, use the AxiChrom™ column control unit to automate the packing process. For additional capabilities, connect the system to the BioProcess™ Resin Mixer to handle slurry preparation for the largest AxiChrom™ columns. Visit the products pages for more about AxiChrom™ column control unit and the BioProcess™ resin mixer.

Expanded automation and control options

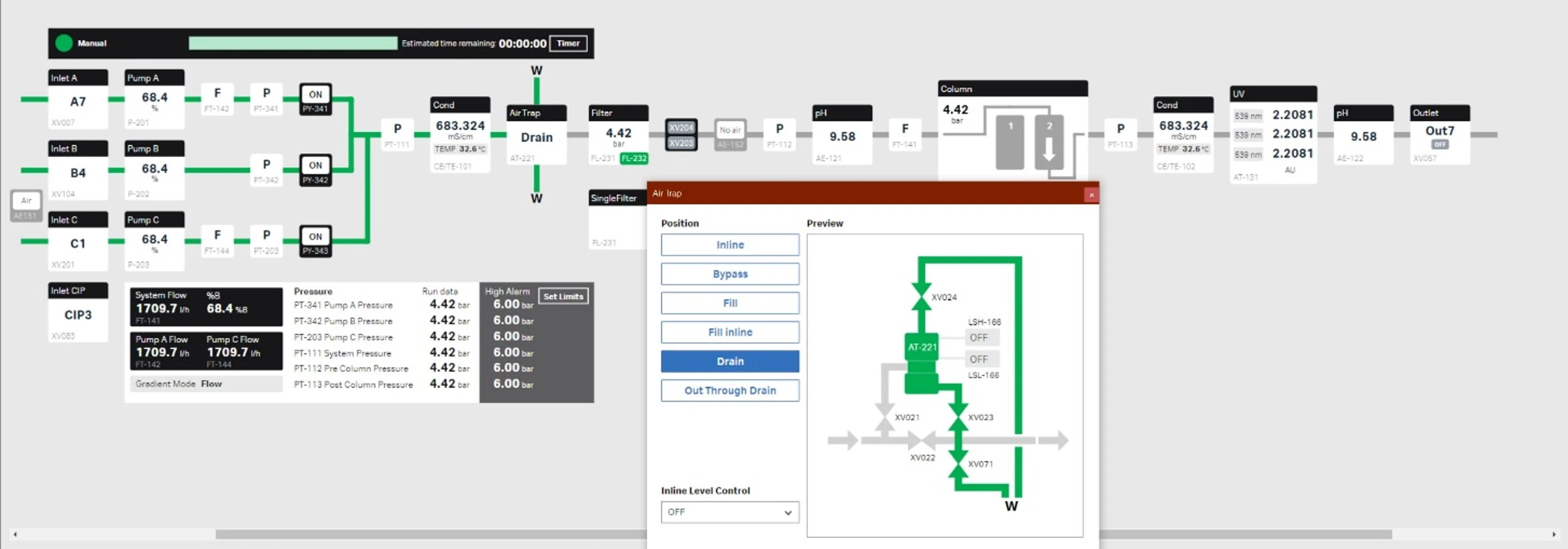

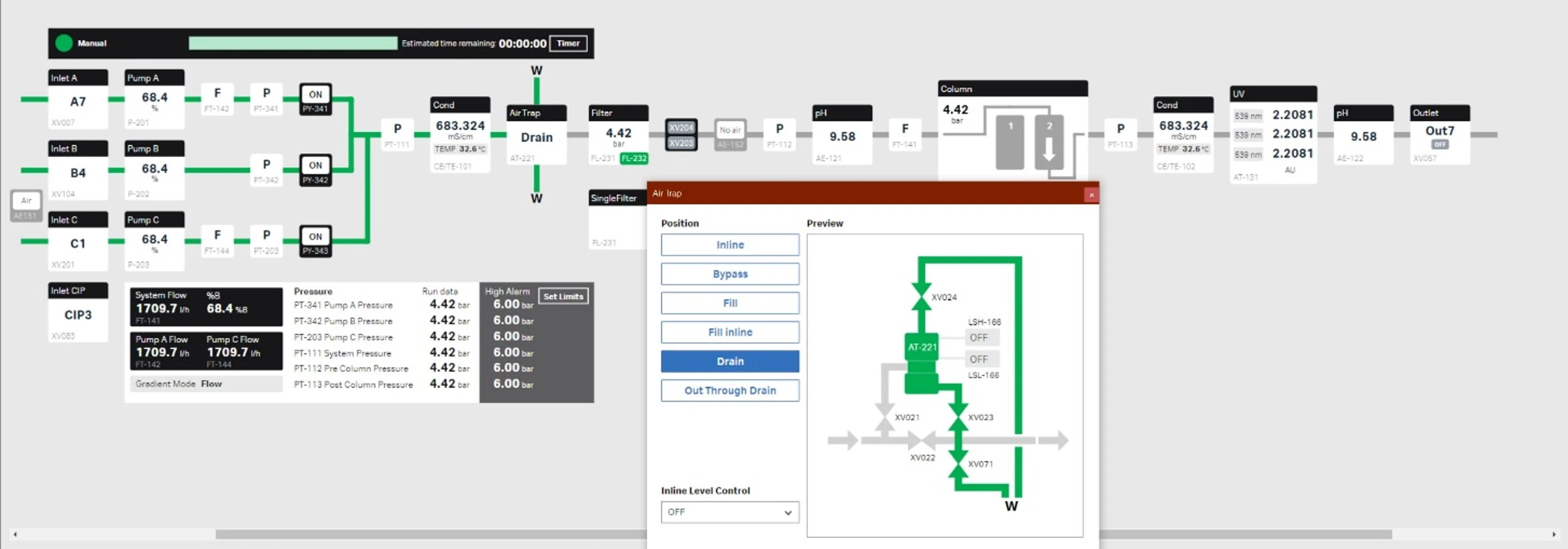

The ÄKTA process™ CFG system includes UNICORN™ software preinstalled on the integrated HMI (human-machine interface), enabling standalone operation and simplified system control.

The software is designed according to GAMP 5 guidelines and can be used in a manner that follows 21 CFR part 11 requirements.

UNICORN™ software has predefined methods with phases for the development of packing, unpacking, priming and column performance test methods for AxiChrom™ columns. The interactive process picture displays key run data, allows the user to set and view manual instructions and alarm limits for components and includes guidance for column packing.

ÄKTA process™ DCS system

For users who require chromatography equipment to be used on their facility’s automation platform, ÄKTA process™ DCS system can be customized with a distributed control system for integration into a plant-wide control system using Open Platform Communications-Unified Architecture (OPC-UA) or EtherNet/IP gateway.

Streamline your sanitization

ÄKTA process™ chromatography system has features to make sanitization with NaOH simple and effective. The cleaning-in-place (CIP) valve placement with the inlet valves drives automated cleaning using UNICORN™ control software. See the application notes below in Product Support that include method instructions for effective cleaning, including ways to reduce the volume of liquid needed or reduce your carbon footprint, to help you meet sustainability goals.

Prepare buffers with inline dilution

Buffer preparation is one of the most resource-intensive activities in downstream processing. Add a third pump to ÄKTA process™ system to support inline dilution (ILD) and prepare buffers at the point of use, saving space, time and costs.

ÄKTA process™ system training support

Find a full list of resources for the system in the Product Support content lower on this page.