Looking for a filter paper, membrane filter, or syringe filter? Let Cytiva help you find the optimal filter for your needs to ensure reliable analysis.

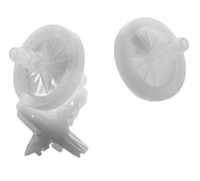

Whatman™ PolyVENT integral vent filters

0.2 µm hydrophobic PTFE air filters work bidirectionally to prevent contamination from entering containers. Biobased plastic options available in the 25 mm size.

Whatman™ PolyVENT integral vent filters

0.2 µm hydrophobic PTFE air filters work bidirectionally to prevent contamination from entering containers. Biobased plastic options available in the 25 mm size.

1. Filtration area

2. Connections

3. Biobased

4. Pack size

Overview

Whatman™ PolyVENT disc filters from Cytiva are integral venting filters that work bidirectionally to prevent contamination from entering containers like fermentation vessels during incubation.

- 0.2 µm hydrophobic PTFE air filters are ideal industrial air filter media

- Validated for 50 steam autoclave cycles; compatible with ethylene oxide (EtO)

- Testable by water break through (WBT) test or bubble point testing

- Passes USP Class VI biosafety tests for plastics

- Manufactured in clean room facilities

- Filtration area 500, 1000, and 2000 cm² to support a range of venting applications

Draining or filling of incubators, fermentation tanks, and other vessels requires a venting filter capable of preventing bacterial contamination. With an integral PTFE filter membrane, Whatman™ PolyVENT acts as an industrial air filter media for sterilization* of gases entering bioreactors such as fermentation tanks.

ISCC+ certified Biobased polypropylene housing (25mm devices):

- 90% Biobased plastic resin.

- Biobased plastic resin is ISCC Plus certified using Mass Balance approach.

- The polypropylene accounts for 95% of the weight/composition of the syringe filters.

Read more on the topic here.

*Refers to sterilization by filtration for small sample use which is an industry term for filters of pore size 0.2 um or smaller as referenced in guidance such as EPA Guidance for Industry Sterile Drug Products Produced by Aseptic Processing — Current Good Manufacturing Practice Section IX, Part B (September 2004).