Pall™ Cadence™ inline diafiltration modules

The Cadence™ inline diafiltration module, part of our Pall filtration portfolio, is designed for continuous processing, in-process buffer exchange or contaminant removal in various processes throughout a wide range of applications.

Pall™ Cadence™ inline diafiltration modules

The Cadence™ inline diafiltration module, part of our Pall filtration portfolio, is designed for continuous processing, in-process buffer exchange or contaminant removal in various processes throughout a wide range of applications.

1. Effective filtration area

2. Membrane material

Overview

The Cadence™ inline diafiltration module, part of our Pall filtration portfolio, is designed for continuous processing, in-process buffer exchange or contaminant removal in various processes throughout a wide range of applications.

The Cadence ILDF technology allows for removal factors of ≥ 3-log. Utilizing conventional TFF cassette building blocks in either Delta regenerated cellulose or Omega™ polyethersulfone membrane ensures accurate scalability and proven selectivity, and low protein binding attributes.

These products utilize proprietary technology, as well as technology licensed from SPF Innovations, and may be covered by one or more patents. See pall.com/patents.

Applications and Operational Benefits

The Cadence inline diafiltration module is designed for continuous processing, in-process buffer exchange or contaminant removal in various processes throughout a wide range of applications in the biopharmaceutical industry. These applications include buffer exchange for final drug substance, desalting or buffer exchange before or after column chromatography, and small molecule contaminant removal.

Enable continuous processing - Until now, there has been a gap in the technology offering for enabling diafiltration in a truly continuous, single-pass method. The Cadence ILDF device fills that gap and is facilitated through the use of staging, providing repetitive dilution/concentration cycles without a re-circulation loop and with significantly smaller system hold-up volume.

High removal factors - The Cadence ILDF technology allows for removal factors of ≥ 3-log. Dialing in the number of diavolumes is easily achieved by adjusting the flow rate on the buffer addition pump and performance is stable over extended operation times.

Optimize processing of highly shear-sensitive products - Processing results in only one pass through the pump and module, therefore reducing shear exposure. Further benefits are achieved by eliminating any mixing or foaming issues associated with the feed tank.

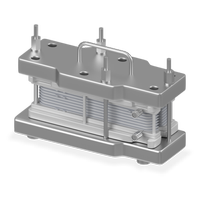

No holder required - Cadence ILDF modules come assembled, and the cassettes and manifolds are configured between two end plates with no extra holder needed. A pre-configured tubing manifold is also provided. Simply torque the device to the recommended setting and attach the tubing manifold to a feed pump and diafiltration buffer pump.

Product Platform Similar to other Cadence SPTFF devices, the Cadence inline diafiltration device utilizes standard Pall T-Series cassettes as the building blocks for the UF/DF tangential flow filtration. These modules are offered with either Delta regenerated cellulose or Omega™ polyethersulfone membranes providing the high flux, high selectivity and low protein binding characteristics that are associated with these membranes. They are available in a range of size formats to accommodate various processing volumes.

A standard PharmaPure♦ tubing manifold is provided with each device, and Sta-Pure♦ tubing manifolds can be ordered separately for extended operation applications (see ordering information).

The Cadence ILDF device requires two standard peristaltic pumps for operation. A 2-headed pump to control the feed and retentate, and a 6-headed pump to control the buffer injection. The feed and retentate lines on the supplied tubing set include PendoTECH pressure transducers and conductivity sensors. A PendoTECH PMAT pressure monitoring device is required to monitor the feed and retentate pressure, and a PendoTECH CMONT device is required to measure conductivity. A torque wrench is also required to torque the module to the recommended level.