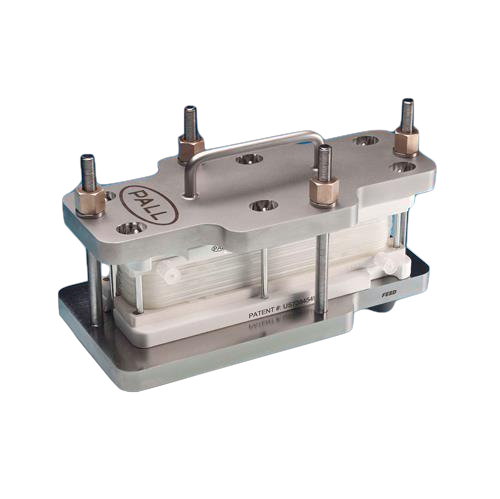

Pall™ Cadence™ single-pass tangential flow filtration (TFF) modules

Cadence™ single-pass tangential flow filtration modules, part of our Pall filtration portfolio, allows direct flow-through concentration with no recirculation of product, which enables high concentration of shear sensitive proteins and antibodies.

Pall™ Cadence™ single-pass tangential flow filtration (TFF) modules

Cadence™ single-pass tangential flow filtration modules, part of our Pall filtration portfolio, allows direct flow-through concentration with no recirculation of product, which enables high concentration of shear sensitive proteins and antibodies.

1. Molecular Weight Cut-Off (MWCO)

2. Effective filtration area

Overview

Cadence™ single-pass tangential flow filtration modules, part of our Pall filtration portfolio, allows direct flow-through concentration with no recirculation of product, which enables high concentration of shear sensitive proteins and antibodies.

Ability to couple the concentration of product before or after other downstream process steps, consequently optimizing other steps and reducing in-process pool tank volumes.

Cadence single-pass TFF modules and systems can be easily integrated with other downstream processes such as chromatography or virus removal.

Using Cadence modules with Delta membrane, the innovative benefits of Single-Pass TFF technology are enhanced by the proven high flux, high selectivity, and low protein binding attributes of Delta regenerated cellulose membrane cassettes.

Optimize Economic and Operational Benefits

Enhance downstream processing to increase capacity and reduce costs – Cadence systems can eliminate or reduce intermediate storage tanks and associated cleaning of tanks when using the systems for in-process volume reduction before or after existing steps.

Increase yield and achieve high product recovery > 98 % – The single-pass TFF process collects most of the process volume during the process run, leaving only a small percentage of the product in the module at the end of the run. This small percentage of product can be easily recovered due to the low hold-up volume in the system.

Enable high concentration factors > 20X – High concentration factors are achieved due to the staging of cassettes in series, which results in high conversions of feed-to-permeate in one flow path. This is accomplished by optimizing the module staging configuration based on cassette performance for a particular application.

Optimize processing of highly shear-sensitive products – Processing results in only one pass through the pump and cassette, reducing shear exposure. For products sensitive to pumping, the pump can be completely eliminated by using pressurized vessels to flow the process fluid through the module. Further benefits are achieved by eliminating any mixing or foaming issues associated with the feed tank.

Use smaller, more compact systems – Cadence systems require less pump capacity, allowing smaller piping or tubing diameters for a more compact system design with lower working and hold-up volumes.

Simplify installation and use – Cadence modules are supplied preassembled. The modules’ feed, retentate and permeate ports are easily connected to clearly-marked system ports.

Product Platform

Innovative single-pass TFF processing takes place within Cadence modules. Cadence modules incorporate T-Series cassettes with Delta membrane, and are available in different sizes to accommodate various processing volumes (see Ordering Information). Cadence modules are designed for use with a Pall Cadence single-pass TFF system.

Cadence Modules Incorporate High Performance T-Series Cassettes with Delta Membrane

Delta regenerated cellulose membrane offers high flux and selectivity. The membrane has been specifically developed to minimize protein binding to the surface and interstitial structure of the membrane. Inherently hydrophilic, this membrane shows low protein adsorption properties and is optimal for processes involving very hydrophilic proteins. Delta regenerated cellulose membrane shows low fouling characteristics, allowing consistent performance or flux from run to run. It is easy to clean and typically recovers normalized water

Shelf Life

The shelf life of Cadence modules packaged in preservative is expected to be two years from the date of manufacture when the modules are stored unopened in the original packaging at ambient temperature up to 25°C and protected from direct light. Extended shelf life studies are ongoing.

Biological Safety

Materials of construction for Cadence modules have been tested and meet the requirements for the Biological Reactivity Tests listed in the United States Pharmacopeia (USP) under USP <88> for Class VI - 70°C Plastics.

Applications

Cadence single-pass TFF modules and systems are used to concentrate biomolecules. They also can be used for salt-level reduction by concentrating followed by in-line dilution. Volume capacities range from several liters to thousands of liters. Single-pass TFF may be used to perform various steps in a wide range of applications in the biopharmaceutical industry, including:

In-process volume reduction

Desalting protein solutions

Purification and recovery of antibodies or recombinant proteins

Preparation of samples (concentrating, desalting) before or after column chromatography

Single-Use Applications

Depending on the application, Cadence modules may also be applied for single use. When applied for single use, Cadence modules are used with a specially-designed Cadence system.

Application Note: Cadence Systems Employ New Single-Pass TFF Technology To Simplify Processes And Lower Costs

The commercialization of a revolutionary TFF technology by Pall Life Sciences presents opportunities to simplify biopharmaceutical process design and lower capital and operational costs. The new technology, single-pass TFF, is brought to life through Pall’s Cadence systems and modules. This Application Note introduces the design innovations of Cadence Single-Pass TFF Systems to biopharmaceutical researchers and manufacturers.

Protein Concentration with Single-Pass Tangential Flow Filtration (SPTFF): This peer-reviewed journal article on the Cadence Single-Pass Tangential Flow Filtration (SPTFF) technology has been published in the Journal of Membrane Science (Volume 384, Issues 1-2, 2011, pp 82-88). The article highlights the novel SPTFF process including:

SPTFF process is continuous, produces high concentration factors, significantly higher conversion in one pass through flow rating control and eliminates the need for the conventional recirculation loop.

Elimination of the conventional recirculation loop minimizes aggregation problems and requires no mixing, minimizes shear exposure and also alows the SPTFF step to be coupled with other downstream process steps.

Additional SPTFF benefits over conventional TFF include lower system hold-up volumes, higher recoveries, and lower flush volume requirements.

Applications that can leverage SPTFF technology include but are not limited tin-process volume reduction, inline salt reduction, high-concentration formulations, and processing of fragile biomolecules.