NanoAssemblr™ Ignite and Ignite+ nanoparticle formulation systems

Easy to use, robust, and scalable systems to accelerate preclinical development of nanomedicines

NanoAssemblr™ Ignite and Ignite+ nanoparticle formulation systems

Easy to use, robust, and scalable systems to accelerate preclinical development of nanomedicines

1. Max volume

2. Max flow rate

Overview

The NanoAssemblr™ Ignite and Ignite+ systems enable scalable, reproducible, and easy-to-use formulation of lipid nanoparticles (LNPs) for preclinical genomic medicine development.

- Accelerated timelines – Simplified workflows and comprehensive technical support expedite drug development and data generation

- Reproducible – Automated and advanced NxGen™ mixing technology minimizes batch-to-batch and user variability to reproducibly generate homogenous particles

- Easy to use – Simple workflows and intuitive software allow users to be up and running quickly

- Minimized risk – The robust design of the system greatly reduces the chances of contamination and user errors, minimizing troubleshooting and downtime

- Controlled assembly – Precise control over fluid flow rates and ratios allows fine-tuning of the critical quality attributes (CQAs), including particle size, to your specifications

- Scalable – The system enables modeling of clinically relevant parameters and processes at small volumes to predictably scale optimized formulations on the NanoAssemblr™ Blaze system and NanoAssemblr™ commercial formulation system

The NanoAssemblr™ Ignite system formulates at the bench scale with volumes of up to 20 mL and flow rates of up to 20 mL/min.

The NanoAssemblr™ Ignite+ system builds on these features with expanded capabilities, formulating up to 60 mL at up to 200 mL/min. This flexibility supports small-scale de-risking of large-scale systems and initiates process development activities using simple, low-volume workflows.

Scalable NxGen™ technology

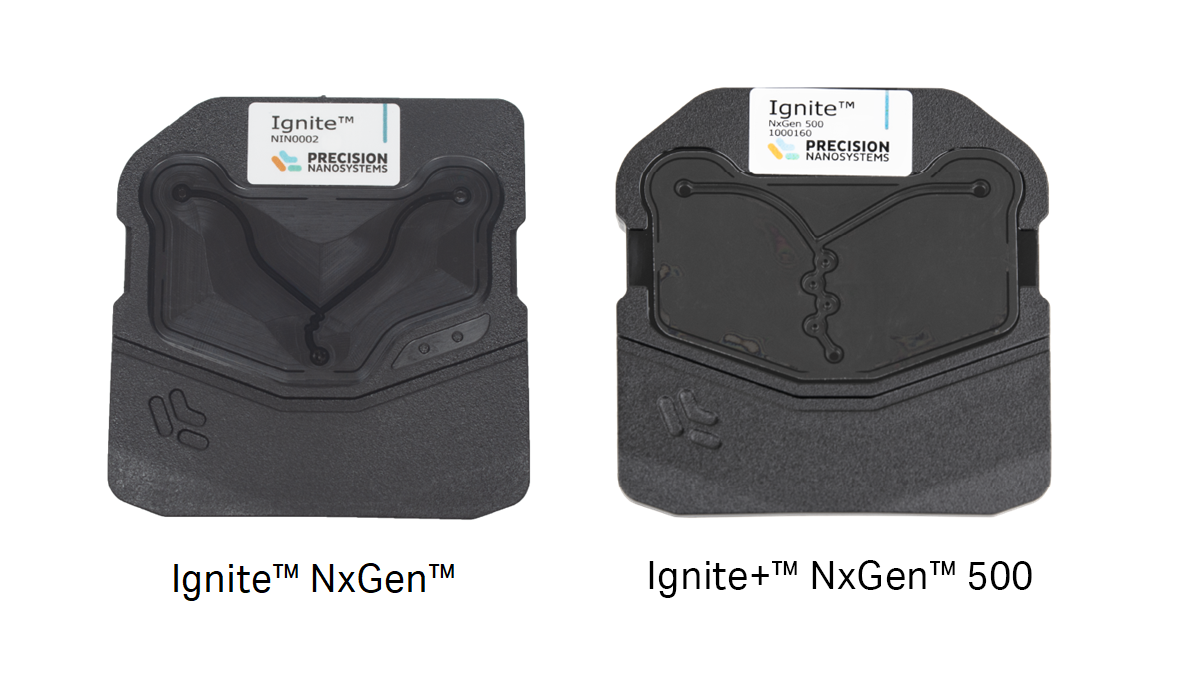

NanoAssemblr™ Ignite and NanoAssemblr™ Ignite+ systems feature NxGen™ technology, an advanced mixing architecture that uses toroidal structures within the flow path to maintain steady, consistent mixing conditions. This enables effective transfer of critical process parameters (CPPs) during scaling up while maintaining reproducibility and control.

All cartridges are validated for single use only. Beginning in September 2025, customers can request a software upgrade that allows optional reuse of current NxGen™ and NxGen™ 500 cartridges. For advanced applications, the new NxGen™ scale-ready cartridge (coming soon) is a gamma-irradiated version of the NxGen™ 500 cartridge, designed with GMP in mind and optimized to minimize risks in early-phase and small-scale clinical trials. Click here to request a software upgrade to enable reusability and/or learn more about the new NxGen™ scale-ready cartridge.

Simple, easy workflow

Quickly prepare LNP formulations using a simple, easy to use workflow requiring minimal setup and training.

Optimize formulations and process parameters

Optimize your formulations by controlling critical process and chemical parameters including flow rate, concentration, and charge. Quick formulation times allow for an efficient systematic approach to finding lead genomic medicine candidates.

Polymer and liposome formulations were optimized by controlling critical process and chemical parameters. A) Starting concentration, B) total flow rate and C) flow rate ratio parameters were varied, and 5 replicates were performed for each data point.

Seamless transfer of manufacturing processes

Establishing new specifications for CPPs including total flow rate (TFR) for large-scale preclinical and clinical systems is critical for successful scale-up. Performing these studies at the bench scale enables the direct protocol transfer of formulation and process parameters to larger systems, new teams, or manufacturing facilities. This ensures CQAs are maintained across scales, saving time and resources while reducing risk during technology transfer.

Critical quality attributes are maintained across a range of flow rates and volumes. Using SARS-CoV-2 self-amplifying RNA (saRNA)-LNPs as a model system, volumes were scaled from 5 mL to 40 mL on Ignite+™ while changing CPPs from the bench scale (12 mL/min, 5 mL) to clinical scale (200 mL/min, 40 mL). CQAs of in-process and finished SARS-CoV-2 saRNA-LNPs including A) size and polydispersity following formulation, in-line dilution and sterile filtration and B) encapsulation efficiency are similar across a range of flow rates and volumes when prepared on Ignite+™. C) Lipid content is also similar across flow rates and volumes.

Related products

Instrument cartridges

NanoAssemblr™ Ignite and Ignite+ cartridges feature NxGen™ technology that allows scale-up through a single mixer from mL/min to L/h.

No priming or cleaning required for an efficient workflow. Ignite™ cartridges are compatible with a wide range of solvents to make a diverse array of nanomedicine formulations.

Automatic In-line dilution cartridges

Automated in-line dilution allows modelling of the processes that will be required for future GMP production of nanoparticles.

Reagents

Expand formulation capabilities and advance genomic medicines with specialized accessories and optimized LNP delivery reagents.

GenVoy-ILM is an off-the-shelf LNP reagent designed to enable the rapid and easy production of RNA-loaded LNPs using the NanoAssemblr™ Ignite™.

GenVoy-ILM T Cell Kit for mRNA is an off-the-shelf LNP reagent mix optimized for the delivery of mRNA or Cas9 mRNA/sgRNA into activated human primary T cells.

Cytiva CD34+ HSC LNP kit is an off-the-shelf LNP reagent mix optimized for the delivery of mRNA or Cas9 mRNA/sgRNA into hematopoietic stem cells.

Cytiva RNA delivery LNP kit is an off-the-shelf LNP reagent with ready–to–use ionizable lipid mix and buffers to fast-track payload screening and RNA drug delivery validation, progressing lead candidates quickly through preclinical studies accelerating clinical evaluation.

Heating Package

The heating package empowers users to heat and keep their formulations in syringes at temperature when operating the Ignite™ and Ignite+™ instruments.