LevMixer™ biocontainer bags

Biocontainer bags for LevMixer™ single-use mixing systems. Made with Allegro™ bioprocess film.

LevMixer™ biocontainer bags

Biocontainer bags for LevMixer™ single-use mixing systems. Made with Allegro™ bioprocess film.

1. Shape

2. Volume

3. Design

Overview

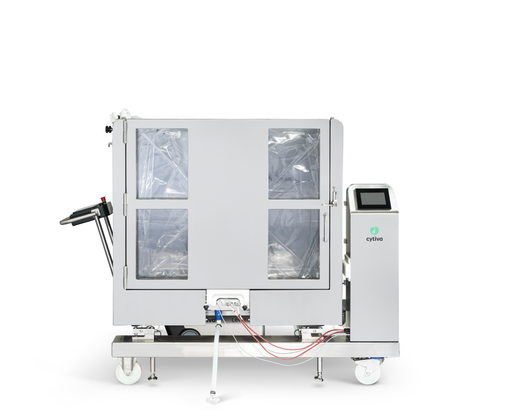

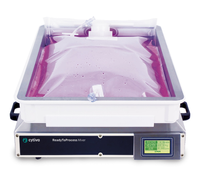

LevMixer™ single-use biocontainer bags include a bottom-mounted, single-use impeller that levitates during operation. The impeller is coupled with a mobile superconductive drive unit, which allows it to rotate while levitating. The biocontainer bags are made from Allegro™ bioprocess film, which is animal-derived component free (ADCF). The bags come in a variety of sizes designed to be fitted into either stainless steel or plastic mixing tanks (30 to 1600 L).

Key features

- Levitating impeller for low shear and minimal particle shed

- Inert, low-density polyethylene contact layer

- High clarity, flexibility, and excellent barrier properties

- Compatible with a wide range of chemicals

- Very low level of extractables and leachables

- Excellent barrier properties

- Animal derived component free (ADCF)

- Complies fully with USP Class VI requirements

- Gamma-irradiated, ready-to-use biocontainers

- Available from 100 mL to 1600 L working volume

Key applications

- Upstream and downstream applications

- Buffer and media preparation

- pH adjustment and reagent mixing

- Viral inactivation and TFF retentate vessel

- Fill and finish

- Product hold

- Shear-sensitive mixing steps

- Process development and manufacturing

| LevMixer™ 10 L biocontainers | LevMixer™ biocontainers | |

| Biocontainer volumes | 10 L | 30 L to 1600 L |

| Shape | Cubical only | Cubical and round options available |

| Biocontainer configurations | Standard, general-use with thermowell, aseptic | Standard, general-use, general-use with thermowell, filtered product, filtered-product sanitary outlet |

| Film | Allegro™ bioprocess film | Allegro™ bioprocess film |

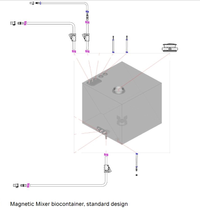

Configurations for LevMixer™ tanks 30 to 1600 L

Standard biocontainer (options available for either cubical or round mixing tanks).

Designed for most standard mixing operations, this configuration offers two top inlets, a4-in. powder port, a bottom drain, and a sampling valve. The connector types used inthis configuration are MPX and MPC.

Filtered product biocontainer (cubical tanks only)

The filtered product biocontainer is designed for closed processing and has no powderport. It has two main inlets and one smaller inlet on the top face, a bottom drain, and asampling valve. The inlet connector types used in this configuration are Kleenpak™ Presto sterile connectors. The outlet connector type is the choice of either a Kleenpak™ Presto sterile connector or a sanitary flange.

General-use biocontainer (cubical tanks only)

Designed for open processing with universal sanitary flange connections. This biocontainer design has two main inlets and two smaller inlets on the top face, a 4-in. powder port, a sampling port, two sensor ports, and a bottom drain. The design is made to be as universal as possible, and it is well suited for applications such as sensing, pH adjustment, buffer prep, and media prep.

General-use biocontainer with thermowell (cubical tanks only)

Designed to offer the same advantages as the general-use biocontainer with a thermowell on the front port. This allows for pH, conductivity, and temperature sensing for applications that require close progress parameter monitoring.

Configurations for LevMixer™ 10 L single-use mixing system

LevMixer™ 10 L single-use mixing biocontainers are available in multiple configurations to support open or closed processing:

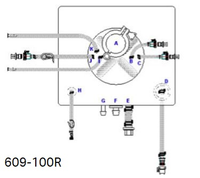

Standard biocontainer

The standard MPC connector design is the most basic with one bottom inlet and one outlet line, both with MPC connectors. The MPC design also contains a sampling line. There is no powder port, no single-use pH sensor, and no inflation line on this design.

General-use biocontainer

General-use biocontainer designs are well suited for open processing and include vendor-agnostic Tri-Clamp sanitary flange connections. General-use designs have one bottom inlet, two top inlets, a powder port, an outlet port with sampling, and a thermowell for temperature sensing. Optional features include a pre-installed, single-use pH sensor and inflation line. The design is made to be as universal as possible, and it is well suited for pH adjustment, buffer prep, media prep, and other applications.

Aseptic processing biocontainer

The aseptic processing designs are intended for closed processing (e.g., no open powder port). These biocontainers have one bottom inlet, two top inlets, and an outlet line, all with intrinsic sterile connectors for closed processing. The design also includes a thermowell for temperature sensing and a sampling line. Optional features include a pre-installed, single-use pH sensor and inflation line.

Flexibility designed in

LevMixer™ single-use biocontainer bags (30 to 1600L) are part of a modular mixing system family that also includes magnetic mixer systems. They use the same tanks and interchangeable drive units to enable maximal flexibility. By swapping out drive units and using the corresponding biocontainer bag, you will have a single-use mixing system that can take you from buffer or media preparation all the way through to final filling process steps.

| Category | Product |

|---|---|

| Tanks | LevMixer™ and magnetic mixer tanks |

| Drive unit | LevMixer™ drive unit |

| Powder bags (10 to 1600 L) | PD2 powder handling bags |