Videos

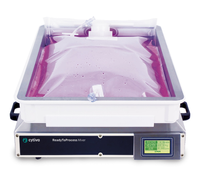

Xcellerex™ XDUO single-use mixing system

This configurable, plug-and-play single-use mixer features powerful automation capabilities with robust mixing and continued support.

Xcellerex™ XDUO single-use mixing system

This configurable, plug-and-play single-use mixer features powerful automation capabilities with robust mixing and continued support.

Volume

Overview

- Configurability comes standard – volumes from 50 L to 2500 L, jacketed or non-jacketed. Enables data management on connected systems for batch record requirements in GMP manufacturing environments, enabling you to be 21 CFR Part 11 compliant, and eliminating the need for paper logs.

- Integrates seamlessly with ÄKTA ready™ extended system, enabling automation and connection of your unit operation, powered by UNICORN™ software.

- A human touch – backed by Cytiva service and support to keep you up and running throughout the years.

XDUO mixing systems are suitable for commercial and clinical production of biopharmaceuticals, vaccines, and other biologics. They support upstream and downstream applications for automated mixing of buffer, media, product and intermediates, and other process fluids. The smart automation and process control capabilities of the XDUO range make complex and sensitive upstream cell culture and downstream purification/separation operations easier. Talk to your local product sales specialists about reducing minimum volume requirements.

Additional benefits of the XDUO:

- Easy interface: The onboard instrument panel immediately initiates the unit's operations and mixing process upon start-up. Digital touch-operated HMI display ensures that trends are clearly shown in raw and graphical representation on the instrument panel display.

- OPC UA and Ethernet/IP compatibility, output to data historians.

- The onboard motor eliminates the need for a separate drive unit, saving time and floor space. Control can be performed locally or remotely for Xcellerex™ FlexFactory™ (using M-station) and other biomanufacturing platforms (using X-station), avoiding manual control.

- Unified control of integrated systems can control pH, temperature, monitor weight, conductivity, and temperature within UNICORN™ software.

- The 2500 L model features dual impellers with the same integrated magnetically coupled drives as the smaller sizes, for faster setup and mixing times.

- Fortem film biocontainer bags available in standard and plus configurations with blunt end, ReadyMate, Tri-Clamp, and AseptiQuik® connector compatibility. Customization is possible. Plus, standard UF/DF mixer biocontainers are designed specifically to work with XDUO mixers as a retentate vessel.

The data files in the Product Support section below provide detailed product specifications and additional product insights, including recommended applications and bag-assembly information.

Related products

| Category | Product | Part number |

|---|---|---|

| Biocontainers | Xcellerex™ XDM single-use mixer bags with Fortem™ film (fit the XDUO mixing system) | Multiple |

| Probes | Assure probe sheath (4) | 29207815 |

| Probe sheath (4) | 29041158 | |

| Insert pH, 12 × 225 mm, Hamilton, VP | 817-00144 | |

| Insert conductivity, 12 × 225 mm | 817-80003 | |

| Reusable probe stand autoclave | 826-00304 | |

| Probe clamp pliers | 29041784 | |

| Manifolds | Sample manifold (2) | 29041165 |

| Sample manifold (4) | 29041166 | |

| Sample manifold (10) | 29041167 | |

| Powder bags | 5 kg Fortem™ film powder bag | 29399774 |

| 10 kg Fortem™ film powder bag | 29399775 | |

| 5 kg powder bag | 29041168 | |

| 10 kg powder bag | 29041169 |

Service and Support

In our customers’ own words

"The instrument itself has been a life-changer, and the support (both technical and service) from Cytiva has been exemplary."

"Service desk and service technician (Mike Black) have made working with Cytiva a pleasure during a time of high stress when production is in progress."

OptiRun service solutions offer a comprehensive range of options that can be customized to your asset-management needs and desired outcomes. Learn more about service agreements, extended warranty, and lifecycle support for your equipment.

Change Control Notifications

Our web-based change control notification (CCN) service notifies you of changes that could potentially impact your product or process.

The CCN service is available for free by subscription at the Regulatory Support website.